How Much Does Water Jet Cutting Cost?

If you’re exploring manufacturing options for your project, you’ve likely asked this very question. Water jet cutting, a versatile and powerful machining process, is renowned for its ability to cut virtually any material with precision and no heat-affected zones. But for many, the pricing structure remains a mystery. Unlike a standard product with a fixed price tag, the cost of a water jet cutter service is influenced by a complex interplay of factors.

This article will demystify the expenses involved, whether you’re considering hiring a service or investing in your own machine. We’ll break down the pricing models, explore the market for a new or used water jet cutter for sale, and introduce you to a leading brand in the industry.

What is a Water Jet Cutter and How Does It Work?

Before diving into costs, it’s essential to understand the technology. A water jet cutter, also known as a hydro cutting machine, is a tool that uses a very high-pressure stream of water, often mixed with an abrasive substance like garnet, to cut through materials.

There are two primary types:

Pure Water Jet Cutting: Uses only highly pressurized water to cut softer materials like foam, rubber, food, and insulation.

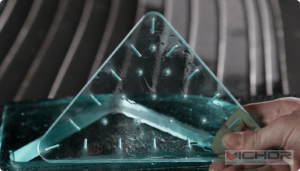

Abrasive Water Jet Cutting: Mixes an abrasive grit into the water stream, enabling it to cut through hard materials like metal (steel, titanium, aluminum), stone, glass, and ceramic.

The process is cold, meaning it doesn’t generate heat that can alter the material’s properties, making it ideal for heat-sensitive applications. This versatility is a key reason why businesses across aerospace, automotive, art, and architecture rely on this technology.

Breaking Down the Cost of Water Jet Cutting Services

When you outsource your cutting work to a service provider, you’ll typically encounter a few standard pricing models. Understanding these will help you decipher any quote you receive.

1. Cost Per Hour (Machine Time)

This is one of the most common methods. Shops calculate an hourly rate based on their operational costs. This rate can range from $60 to $300+ per hour. The wide range depends on:

Machine Capability: High-pressure pumps (e.g., 60,000 psi vs. 90,000 psi) command a higher rate due to faster cutting speeds.

Overhead: Facility costs, labor, and administrative expenses are factored in.

Location: Shops in regions with higher costs of living typically charge more.

2. Cost Per Inch (Linear)

For many projects, especially those with long, complex cuts, a per-inch price is more accurate. Providers calculate the total length of the cut path and charge a rate per linear inch. This rate is often $0.15 to $1.50 per inch, influenced by:

Material Type and Thickness: Cutting a 2-inch thick titanium plate costs significantly more per inch than cutting 1/4-inch acrylic.

Tolerances and Complexity: Simple shapes are cheaper. Intricate designs with tight corners and high precision require slower cutting speeds, increasing the cost.

3. Cost Per Part

For high-volume production runs, shops may offer a flat rate per part. This simplifies the quote and can be more economical for the customer as the provider optimizes their process for efficiency.

Key Factors That Directly Impact Your Quote:

Material Cost: You are paying for the raw material sheet plus a markup.

Abrasive Cost: Garnet abrasive is a significant consumable. Thicker materials require more abrasive, adding to the cost.

Piercing Time: The time taken to pierce the material at the start of a cut. Multiple pierces for a nest of parts add up.

Set-Up and Programming: Simple one-off projects have minimal setup. Complex projects requiring custom programming or fixturing will incur additional charges.

Labor: Handling, finishing (deburring), and quality inspection time.

Investing in Your Own Hydro Cutting Machine

For businesses with consistent, high-volume needs, purchasing a machine becomes a compelling option. This eliminates per-job costs and offers complete control over your production schedule. The market for a water jet cutter for sale is vast, ranging from small desktop systems to massive industrial platforms.

New vs. Used Water Jet Cutter Price

The price spectrum is broad, primarily determined by size, power, and features.

Entry-Level/Tabletop Systems: Small 5′ x 5′ or 4′ x 8′ machines with lower pressure pumps can start from $60,000 to $120,000.

Standard Industrial Systems: A robust 5′ x 10′ machine with a high-pressure pump (60,000-90,000 psi) from a reputable brand like VICHOR typically ranges from $150,000 to $300,000.

Large-Format/Custom Systems: Machines with tables exceeding 10′ x 20′ or with specialized automation can easily cost $400,000 to over $1,000,000.

A used water jet cutter for sale can offer significant savings, often 30-50% less than a new equivalent. However, this comes with risks: potential hidden maintenance issues, outdated software, and lack of a warranty. Thorough inspection and service history review are crucial.

The Total Cost of Ownership

The purchase price is just the beginning. When budgeting for a water jet cutter, you must consider operational costs:

Abrasive (Garnet): A major ongoing expense.

High-Pressure Pump Maintenance: Seals, valves, and intensifiers need regular replacement.

Nozzles and Focusing Tubes: These are wear items with a limited lifespan.

Electricity: The pumps and motors are significant power consumers.

Water: Requires a filtration and deionization system to protect the pump.

Labor: A trained operator is needed.

Brands like VICHOR have focused on engineering machines that not only offer high performance and precision but also improved efficiency, reducing abrasive consumption and energy use to lower the total cost of ownership for their customers.

VICHOR: A Synonym for Precision and Reliability

In the world of hydro cutting machine manufacturers, VICHOR has established itself as a leader known for innovation and durability. A VICHOR water jet cutter is engineered for high productivity and exceptional cut quality. They offer a range of models to suit different needs and budgets, from versatile standard gantries to fully automated cutting cells. For a business evaluating a water jet cutter for sale, considering a brand like VICHOR means investing in robust technology backed by engineering support, which is vital for minimizing downtime and maximizing return on investment.

Common Questions About Water Jet Cutter Price and Process

Q: What is the minimum order quantity for a water jet cutting service?

A: Many shops have no minimum order, making it great for prototypes. However, setup costs make one-off parts more expensive per unit. Volume discounts usually apply for larger orders.

Q: How accurate is water jet cutting?

A: It is extremely accurate. Modern machines like those from VICHOR can hold tolerances as tight as ±0.003″ (±0.076 mm) or better, depending on the material and thickness.

Q: Can a water jet cutter create internal threads?

A: No. The stream creates a slightly tapered kerf and cannot create the helical structure of a thread. Threads would need to be tapped after the cutting process is complete.

Q: How does the water jet cutter price compare to laser or plasma cutting?

A: Laser: Generally faster for thin metals but can’t cut reflective materials (e.g., copper, aluminum) or thick plates as effectively. Laser generates heat. Plasma: Much cheaper for thick steel but with a larger heat-affected zone and lower precision. Water jet is the most versatile, cold-cutting option but can be slower and more expensive for some applications.

Q: What file format do I need to provide for a quote?

A: Vector files are required. The industry standard is DXF (Drawing Exchange Format). Other acceptable formats include DWG, AI, and sometimes PDF.

So, how much does water jet cutting cost? The answer is, “it depends.” For services, your project’s complexity, material, and volume dictate the price. For a machine, the water jet cutter price is an investment in long-term capability, with costs spread across the machine’s lifespan.

The best approach is to start with detailed CAD drawings of your part. Reach out to several reputable service providers for quotes. If your projects are constant and growing, use those service costs to build a business case for purchasing your own hydro cutting machine. Whether you choose the flexibility of a service or the control of owning a machine like a VICHOR water jet cutter, this technology offers unparalleled manufacturing flexibility that can bring even the most complex designs to life.

continue reading

Related Posts

- 1077 words5.4 min read

- 1175 words5.9 min read

- 1255 words6.3 min read