7 Fascinating Ways a Water Jet CNC Machine Transforms Manufacturing

In the ever-evolving world of manufacturing and fabrication, few tools command as much respect and intrigue as the water jet CNC machine. It’s a technology that seems almost paradoxical: using a high-pressure stream of water, sometimes mixed with an abrasive substance, to slice through solid materials with incredible precision. This isn’t just a powerful tool; it’s a versatile and innovative solution that has revolutionized how industries approach cutting. This article dives deep into seven key aspects that make water jet CNC technology a cornerstone of modern production.

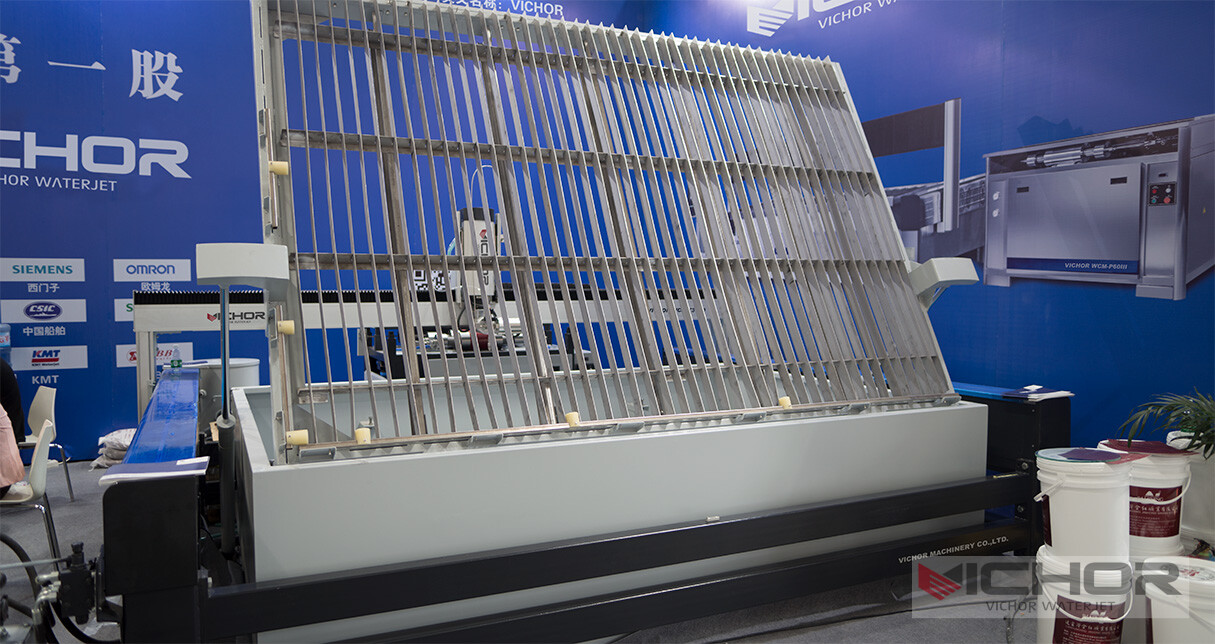

How a Water Jet CNC Machine Actually Works

At its core, a water jet CNC system is a marvel of engineering that transforms ordinary tap water into an industrial-grade cutting tool. The process begins with a high-pressure pump, which is the heart of the machine. This pump intensifies the water pressure to an astonishing degree, typically between 60,000 and 90,000 Pounds per Square Inch (PSI).

This ultra-high-pressure water is then forced through a small orifice, usually made of sapphire or diamond, located in the cutting head. This orifice focuses the stream into a coherent jet moving at speeds several times the speed of sound. For cutting harder materials like metals, stone, or ceramics, a granular abrasive (often garnet) is introduced into the stream right after the orifice. The abrasive particles mix with the high-speed water, creating an erosive action that grinds through the material. The entire cutting head is mounted on a computer numerically controlled (CNC) gantry system, which moves it with extreme accuracy along the X, Y, and Z axes according to a digital design file, ensuring perfect cuts every time.

The Unmatched Versatility of Materials

Perhaps the most significant advantage of water jet CNC cutting is its extraordinary material versatility. Unlike laser or plasma cutters, which are limited by a material’s thermal properties, water jet is a cold-cutting process. This allows it to cut virtually any material without altering its intrinsic structure.

Metals: From soft aluminum and copper to tough titanium, tool steel, and stainless steel.

Stone and Tile: Granite, marble, slate, and ceramic tiles are cut smoothly without chipping.

Glass: It can create intricate designs in laminated, tempered, or stained glass without cracking it.

Composites: Ideal for carbon fiber and fiberglass, as it avoids delamination and fraying.

Plastics and Rubber: Cuts through thick plastics, rubber sheets, and foam without melting or releasing toxic fumes.

Exotic Materials: It can even handle materials like Kevlar and bulletproof glass.

This “one-tool-cuts-all” capability makes the water jet CNC an invaluable asset for job shops and factories that work with diverse material inventories.

Precision and Accuracy in Cutting

When we talk about precision in the context of a water jet CNC machine, we are referring to its ability to hold incredibly tight tolerances, often within ±0.001 inches (±0.03 mm). The CNC component ensures that this level of accuracy is consistent and repeatable across multiple parts. The kerf, or the width of the cut, is very narrow, determined by the stream diameter (typically between 0.02″ and 0.05″). This minimizes material waste and allows for intricate detailing and nesting of parts to optimize raw material usage.

Furthermore, because there is no heat-affected zone (HAZ), the edges of the cut material remain pristine and unaltered. There is no hardening, warping, or micro-fracturing, which is a common issue with thermal cutting processes. This means parts often require little to no secondary finishing, saving both time and money.

The Critical Advantage of a Cold Cutting Process

The cold-cutting nature of the water jet CNC process cannot be overstated. Heat is a destructive force in machining. It can weaken the structural integrity of metals, create hardened edges that are difficult to machine later, cause warping in thin materials, and burn or melt plastics.

By using a stream of cold water (often room temperature), the water jet CNC system completely eliminates these thermal drawbacks. The material being cut remains at or near ambient temperature throughout the process. This is absolutely crucial for industries where the material’s metallurgical or structural properties must remain unchanged, such as in aerospace components or military applications. It also ensures the safety of operators by not creating a fire hazard when cutting flammable materials.

Exploring the Wide-Ranging Applications and Industries

The unique combination of versatility, precision, and cold-cutting power has led to the adoption of water jet CNC technology across a vast spectrum of industries.

Aerospace and Aviation: Used for cutting intricate parts from titanium, aluminum alloys, and composites for airframes and engines, where material integrity is paramount.

Architecture and Art: Artists and architects use it to create complex sculptures, detailed inlays for floors, intricate stone facades, and custom signage.

Automotive: Manufacturers use it for cutting gaskets, interior trim, body panels, and even custom parts for luxury and racing vehicles.

Food Industry: Surprisingly, pure water jets (without abrasive) are used in the food sector for cutting cakes, frozen foods, fish, and poultry. It’s a hygienic and precise method that doesn’t contaminate the product.

Manufacturing and Machine Shops: This is the broadest application, where job shops use water jet CNC as a primary or secondary service to produce parts for everything from mining equipment to consumer electronics.

Environmental Impact and Sustainability

In an era focused on green manufacturing, the water jet CNC process stands out for its environmental friendliness. The primary “cutting tool” is water and natural abrasive (garnet), both of which are non-toxic and naturally occurring. The process does not produce hazardous fumes, gases, or dust that require expensive ventilation or filtration systems. Furthermore, the water used in the process can often be recycled and reused within a closed-loop system, significantly reducing consumption. The waste material is typically just the cut scraps and spent abrasive, which are generally inert and easier to dispose of compared to the waste from other industrial processes.

Understanding the Limitations

While incredibly powerful, water jet CNC technology does have some limitations to consider. The cutting speed, especially for thick, hard materials, can be slower than that of plasma or laser cutters. Operating and maintaining the ultra-high-pressure pumps requires specialized knowledge and can be costly. There is also the ongoing cost of consumables, such as the abrasive material and the orifice/nozzle components. Finally, while the kerf is narrow, the water stream is slightly tapered, meaning the top of the cut is ever so slightly wider than the bottom. However, modern CNC systems can compensate for this taper with advanced programming to produce near-perfectly straight edges.

In conclusion, the water jet CNC machine is far more than just a powerful cutter; it is a testament to innovation in manufacturing. Its ability to handle an unparalleled range of materials with cold, precise, and environmentally conscious power makes it an indispensable tool. From the workshop floor to the artist’s studio, this technology continues to transform ideas into tangible reality, proving that sometimes, the most powerful force in fabrication is, quite literally, a stream of water.

continue reading

Related Posts

- 1077 words5.4 min read

- 1175 words5.9 min read

- 1255 words6.3 min read