5 Fascinating Ways Water Jet Pressure Cuts Through Solid Steel

In the world of industrial manufacturing and fabrication, cutting through incredibly hard materials like steel is a daily challenge. While lasers, plasma torches, and saws have their place, one technology stands out for its cool, precise, and versatile nature: using extremely high water jet pressure to cut steel. This process, which might seem like something from science fiction, is a well-established and highly efficient method for slicing through metal with astonishing accuracy. This article delves into the science, applications, and advantages of using pressurized water as a cutting tool.

The Core Principle: How Pure Water Transforms Into a Cutting Tool

At its heart, the process is deceptively simple. It’s all about harnessing the power of intense pressure. A standard waterjet pump takes ordinary tap water and pressurizes it to an extreme degree, typically between 60,000 and 90,000 Pounds per Square Inch (PSI). To put that into perspective, the pressure from a fire hose is around 300 PSI; a waterjet operates at pressures several hundred times greater.

This ultra-high-pressure water is then focused through a small, precision gemstone nozzle (often made from diamond or sapphire), creating a coherent stream moving at speeds up to three times the speed of sound. When we talk about using water jet pressure to cut steel, this pure water stream is effective for softer materials. However, for hard metals, an additional component is needed to do the actual cutting.

The Role of Abrasive Garnet in Cutting Hard Steel

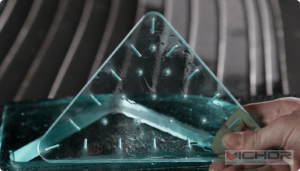

Pure water, even at these tremendous pressures, cannot efficiently cut through hardened or thick steel. This is where the process evolves into “abrasive waterjet cutting.” Just after the pure water stream exits the nozzle, it enters a mixing tube where a specially processed mineral, typically garnet, is sucked into the stream via a vacuum effect.

The incredibly fast-moving water particles accelerate these hard, abrasive garnet particles, transforming the water stream into a potent erosive tool. It is this abrasive slurry—the combination of high-water jet pressure and the hard garnet—that microscopically erodes the steel, creating a clean, precise cut. Think of it as using a super-high-pressure sandblaster that is focused into a single, tiny beam. The abrasive additive is the key that unlocks the ability to use water jet pressure to cut steel of virtually any type and thickness.

Why Choose Waterjet? The Unmatched Advantages

So, why would a fabricator choose this method over more traditional tools? The benefits are numerous and significant:

No Heat-Affected Zone (HAZ): This is the single biggest advantage. Unlike plasma or laser cutting, which use extreme heat to melt through metal, a waterjet is a cold-cutting process. The water jet pressure to cut steel does not generate heat, meaning the structural properties of the steel remain unchanged. There is no hardening, warping, or residual stress introduced along the cut edges, which is critical for precision components.

Material Versatility: A waterjet is the ultimate omnivore of cutting tools. The same machine can cut steel, aluminum, titanium, stone, glass, rubber, composites, and food products. There is no risk of cross-contamination or chemical changes, making it ideal for projects involving multiple materials.

Exceptional Precision and Quality: Waterjets produce incredibly accurate cuts with a very narrow kerf (the width of the cut). Modern systems are CNC-controlled, allowing for the execution of complex shapes and intricate designs with tight tolerances, often without the need for secondary finishing.

Environmental and Safety Benefits: The process generates no hazardous fumes or gases, as it doesn’t involve combustion or melting. The primary waste product is the used garnet and small metal particles, which are generally non-toxic and can often be recycled or disposed of easily.

Understanding the Numbers: Pressure, Thickness, and Cut Speed

The effectiveness of using water jet pressure to cut steel is governed by a few key factors. The relationship between pressure, material thickness, and cutting speed is direct and critical.

Higher pump pressure allows for faster cutting speeds and the ability to cut thicker materials. For example, a 60,000 PSI pump might cut through 2-inch thick steel at a certain speed, while a 90,000 PSI pump could cut the same steel significantly faster or handle even thicker plates. The desired cut quality also plays a role; a slower cut speed will produce a smoother edge finish, while a faster speed might be used for rougher cuts where edge quality is less important. Operators carefully balance these parameters—pump pressure, abrasive flow rate, and traverse speed—to achieve the perfect cut for each specific job.

The Diverse Industrial Applications of Waterjet Cutting

The unique capabilities of this technology make it indispensable across a wide range of industries. The use of water jet pressure to cut steel and other materials is found in:

Aerospace and Aviation: For cutting high-strength alloys, titanium components, and composite materials without compromising their integrity.

Automotive: Used for prototyping, creating interior components, and cutting intricate parts for custom vehicles and production lines.

Architecture and Art: Favored by artists and architects for creating detailed metal sculptures, decorative panels, and intricate inlays in steel and other metals.

Manufacturing and Machine Shops: A workhorse for producing parts, tools, and components from plate metal, especially when designs change frequently, as there are no expensive tooling requirements.

In conclusion, the technology behind using water jet pressure to cut steel is a remarkable fusion of simplicity and brute force. By propelling water and abrasive particles at supersonic speeds, it achieves what heat-based tools cannot: perfect, cold, precise cuts in almost any material. Its versatility, precision, and lack of thermal distortion secure its place as an essential and powerful tool in modern industry, continuing to push the boundaries of what is possible in fabrication and design.

continue reading

Related Posts

- 1077 words5.4 min read

- 1175 words5.9 min read

- 1255 words6.3 min read