The Ultimate Guide to Micro Water Jet Cutting: Precision, Versatility, and Innovation

In the ever-evolving world of precision manufacturing, the demand for technologies that can cut intricate, delicate, or complex materials without compromising their integrity is higher than ever. Among the front-runners in this field is Micro Water Jet Cutting, a process that harnesses the power of ultra-high-pressure water, often mixed with fine abrasives, to achieve remarkably precise cuts. Unlike traditional cutting methods that rely on heat, micro water jet cutting offers a cold-cutting alternative, eliminating heat-affected zones (HAZ) and thermal distortion. This makes it an indispensable tool for industries where precision is paramount, from medical device manufacturing to electronics and aerospace. This comprehensive guide will delve into the intricacies of micro water jet cutting, exploring its fundamental principles, numerous advantages, diverse applications, key system components, and crucial considerations for implementation. By understanding the full potential of this technology, businesses can unlock new possibilities in design and production.

What is Micro Water Jet Cutting and How Does It Work?

Micro Water Jet Cutting is an advanced subtractive manufacturing process that evolved from conventional waterjet cutting. While a standard waterjet can generate a stream around 0.030 to 0.060 inches (0.76 to 1.5 mm) in diameter, micro water jet cutting focuses on achieving drastically smaller jet diameters, typically in the range of 0.003 to 0.015 inches (0.076 to 0.38 mm). This reduction in size is what allows for exceptional precision, with kerf widths as small as 0.002 inches (0.05 mm) and tolerances within ±0.0005 inches (±0.013 mm).

The core principle remains the same: pressurizing water to extreme levels. Here’s a step-by-step breakdown of the process:

Pressurization: A high-pressure pump, either intensifier or direct-drive type, pressurizes ordinary tap water to incredibly high levels, typically between 60,000 to 94,000 PSI (4,000 to 6,500 bar).

Orifice: This ultra-high-pressure water is then forced through a precisely engineered gemstone orifice, usually made of sapphire or diamond. The orifice is the first critical component for miniaturization, as its small diameter (often 0.004-0.012 inches) creates a coherent, high-velocity stream.

Abrasive Introduction (For Abrasive Micro Cutting): For cutting harder materials like metals, ceramics, or composites, an abrasive material (such as garnet) is introduced into the stream. This happens in a mixing chamber located just after the orifice. The vacuum created by the high-speed water stream pulls abrasive into the head, where it is accelerated and focused through a focusing tube (or nozzle), typically made of tungsten carbide.

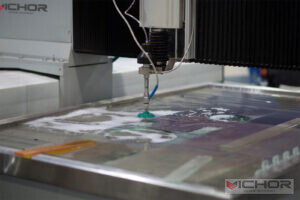

Cutting: The resulting stream—a supersonic mixture of water and abrasive particles—is ejected from the nozzle and directed onto the workpiece by a CNC (Computer Numerical Control) system. This system moves the cutting head along a programmed path with extreme accuracy, eroding the material away particle by particle to create a clean, precise cut.

The “micro” aspect is achieved through several technological advancements: smaller orifices and focusing tubes, superior pump stability for consistent pressure, higher accuracy CNC controls, and specialized software that can manage the extreme precision required for such fine details.

The Key Advantages of Adopting Micro Water Jet Cutting Technology

The growing adoption of micro water jet cutting is driven by a unique set of benefits that are difficult to match with other cutting technologies.

Cold Cutting Process: This is arguably its most significant advantage. Since the process uses water and abrasives without generating heat, it completely avoids creating a heat-affected zone (HAZ). This means the material’s inherent properties—hardness, temper, structure—remain unchanged right up to the edge of the cut. This is critical for heat-sensitive materials like tempered glass, certain composites, and exotic metals.

Exceptional Precision and Minimal Kerf: The ability to produce extremely narrow kerfs and hold tight tolerances allows manufacturers to create highly complex and intricate geometries with minimal material waste. This is essential for miniaturized components in the medical and electronics industries.

Versatility in Material Compatibility: Micro water jet cutting is an omni-material process. It can cleanly cut virtually any material, from soft, delicate substances like foam, rubber, and food products to ultra-hard materials like titanium, Inconel, ceramic, and glass. Simply switching from pure water (for soft materials) to abrasive waterjet (for hard materials) is all that’s required.

No Mechanical Stress: Unlike milling or punching, the waterjet process exerts very little mechanical force on the workpiece. This allows for the cutting of very thin and fragile materials without causing distortion or breakage, and enables precise cutting near the edge of a part without fear of cracking.

Environmentally Friendly: The process produces no hazardous fumes or vapors, as it does not involve combustion or melting. The primary waste products are water and spent abrasive, which can be managed and recycled in various ways, making it a cleaner alternative to laser or EDM (Electrical Discharge Machining) in many cases.

Diverse Applications of Micro Water Jet Cutting Across Industries

The unique capabilities of micro water jet cutting have made it a valuable technology across a wide spectrum of high-tech industries.

Medical Device Manufacturing: This industry is a prime beneficiary. Micro water jet cutting is used to manufacture intricate components for surgical tools, implants (e.g., titanium spinal cages, knee implants), and diagnostic devices. Its ability to cut biocompatible materials without altering their properties or creating micro-cracks is invaluable.

Electronics and Semiconductors: The technology is used for precision cutting of circuit boards, creating intricate patterns in insulating materials, and trimming delicate components without subjecting them to thermal stress that could damage embedded electronics.

Aerospace and Defense: The aerospace sector uses micro water jet cutting for machining complex parts from high-strength, heat-resistant superalloys used in turbine engines, as well as for cutting lightweight composite materials and honeycomb structures for airframes without delamination.

Automotive: Applications include cutting gaskets, airbag components, interior trim, and even lightweight composite and carbon fiber parts for high-performance vehicles, all with high precision and no heat damage.

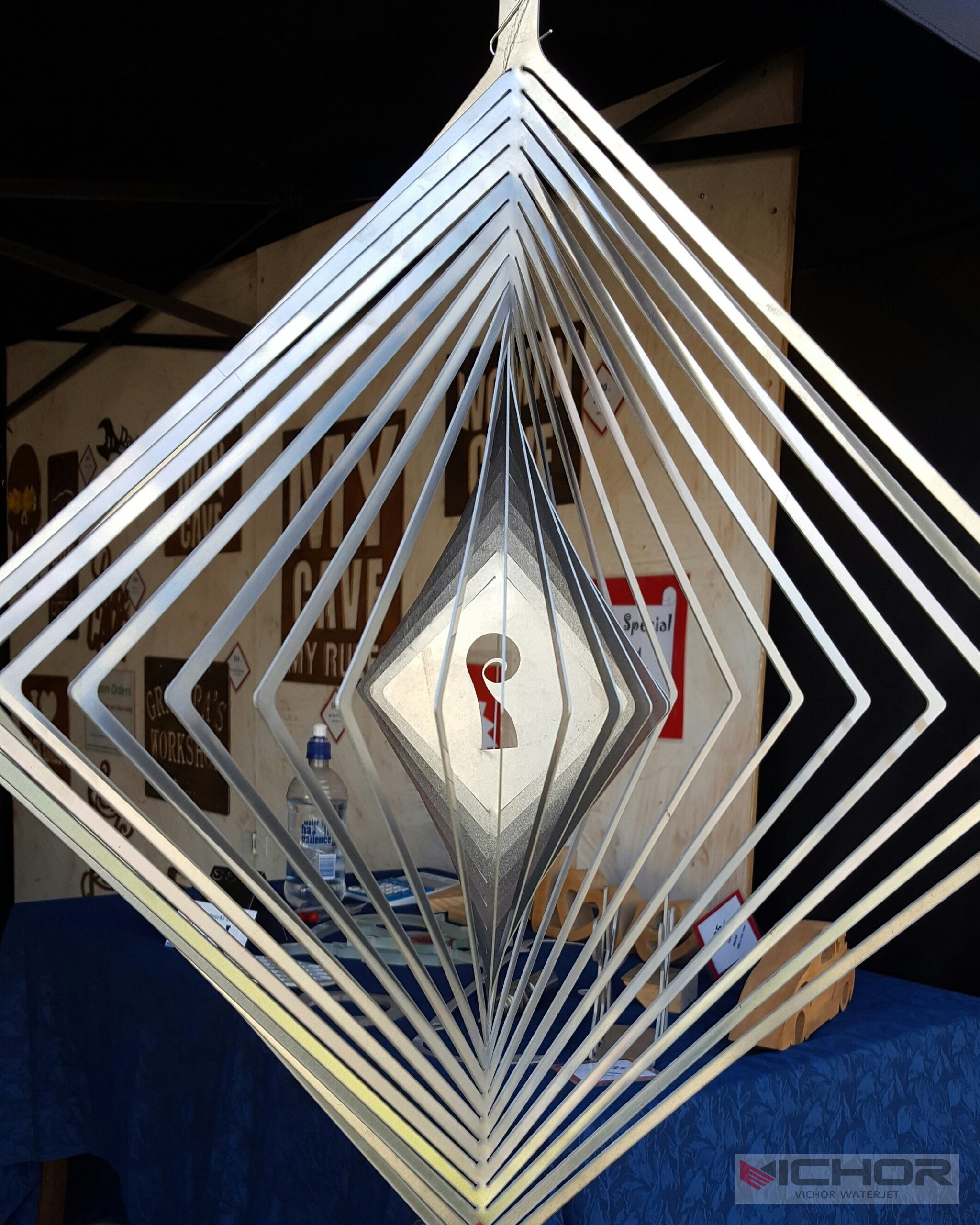

Glass and Ceramics: The technology excels at cutting brittle materials. It is used for creating intricate designs in stained glass, manufacturing electronic substrates, and cutting smartphone glass and touchscreens without creating micro-fractures that can lead to future failure.

Food Industry: On a larger scale, pure waterjet cutting is used for portioning food. The “micro” variant could be applied for precise cutting of delicate food products or for creating intricate patterns and designs.

Critical Components of a Micro Water Jet Cutting System

A reliable micro water jet cutting system is a synergy of several high-tech components, each playing a vital role in achieving precision.

Ultra-High-Pressure Pump: The heart of the system. It must provide stable, pulsation-free pressure at extreme levels to ensure consistent cutting performance. Pump reliability is directly tied to cut quality and operational uptime.

Precision Cutting Head: This is where the magic happens. The micro-cutting head includes the gemstone orifice (sapphire or diamond) and the abrasive mixing chamber and focusing tube. The quality and precision of these consumables are critical for maintaining a coherent, fine jet stream.

CNC Motion System: To leverage the fine jet, the motion system must be exceptionally accurate and smooth. Systems often use precision linear motors or high-quality ball screws and linear guides, coupled with advanced motion control software to minimize vibration and achieve precise positioning at high speeds.

Abrasive Delivery System: For abrasive micro water jet cutting, a consistent and controlled flow of abrasive is essential. This system must meter the abrasive accurately to prevent clogs and ensure an even cut.

CAD/CAM Software: Specialized software is required to convert digital designs (CAD) into machine instructions (CAM). For micro-cutting, the software must handle complex geometries, optimize cutting paths for accuracy and speed, and precisely control the cutting head’s acceleration and deceleration.

Catch Tank & Waste Management: The system requires a tank to contain the high-energy stream after it passes through the material. This tank is often equipped with a water recycling system to reduce waste and operational costs.

Factors to Consider When Implementing Micro Water Jet Cutting

Integrating micro water jet cutting into a production environment requires careful consideration of several factors:

Initial Investment vs. ROI: The technology represents a significant capital investment. The justification comes from the value it adds: the ability to produce complex, high-value parts with reduced secondary processing, less material waste, and higher quality.

Operating Costs: Key consumables include orifices, focusing tubes, high-pressure pump parts, and abrasive material. Understanding these costs and implementing practices to extend consumable life is crucial for economical operation.

Cutting Speed vs. Precision: There is a trade-off. Achieving the highest levels of precision often requires slower cutting speeds. The application will dictate the necessary balance between throughput and accuracy.

Technical Expertise: Operating and maintaining a micro water jet cutting system requires trained personnel. Knowledge of the machine’s mechanics, the pump system, and the CNC software is essential for troubleshooting and achieving optimal results.

Facility Requirements: The system requires adequate space, a reliable power source, and a supply of water and abrasive. The pump can be noisy, so considerations for placement may be necessary.

Micro Water Jet Cutting stands as a testament to the innovation driving modern manufacturing. It successfully bridges the gap between the unparalleled versatility of waterjet technology and the extreme precision demanded by today’s miniaturized and complex components. Its cold-cutting nature, material versatility, and ability to produce intricate geometries without thermal or mechanical stress make it an irreplaceable solution in fields where failure is not an option. As technology continues to advance, with improvements in pump stability, motion control, and software algorithms, the capabilities of micro water jet cutting will only expand further. For any industry seeking to push the boundaries of design and material application, embracing this technology is not just an option—it is a strategic step towards a future of limitless precision and innovation.

continue reading

Related Posts

- 1315 words6.6 min read

- 1300 words6.6 min read

- 1232 words6.2 min read