7 Critical Advantages of Water Jet Cutting for Porcelain Tile Projects

Porcelain tile is renowned for its durability, aesthetic versatility, and resistance to moisture and wear. It’s a premier choice for floors, walls, countertops, and artistic features. However, its renowned hardness, which makes it so durable, also presents a significant challenge: how do you cut it into complex shapes with precision and without damage? Traditional blade cutting often falls short, leading to chipping, cracking, and material waste. This is where the revolutionary technology of water jet cutting porcelain tile comes into play. This advanced method utilizes a high-pressure stream of water, often mixed with an abrasive substance, to slice through hard materials with unparalleled accuracy. In this article, we will explore the seven key advantages that make water jet cutting porcelain tile the preferred method for fabricators, architects, and DIY enthusiasts tackling sophisticated projects.

The Unmatched Precision of Water Jet Cutting

When it comes to intricate designs and exact measurements, no other cutting method can compete with a water jet. Water jet cutting porcelain tile operates with computer numerical control (CNC), meaning the machine follows a digital design file with extreme accuracy, typically within a tolerance of +/- 0.005 inches (0.13 mm).

This precision is crucial for several applications:

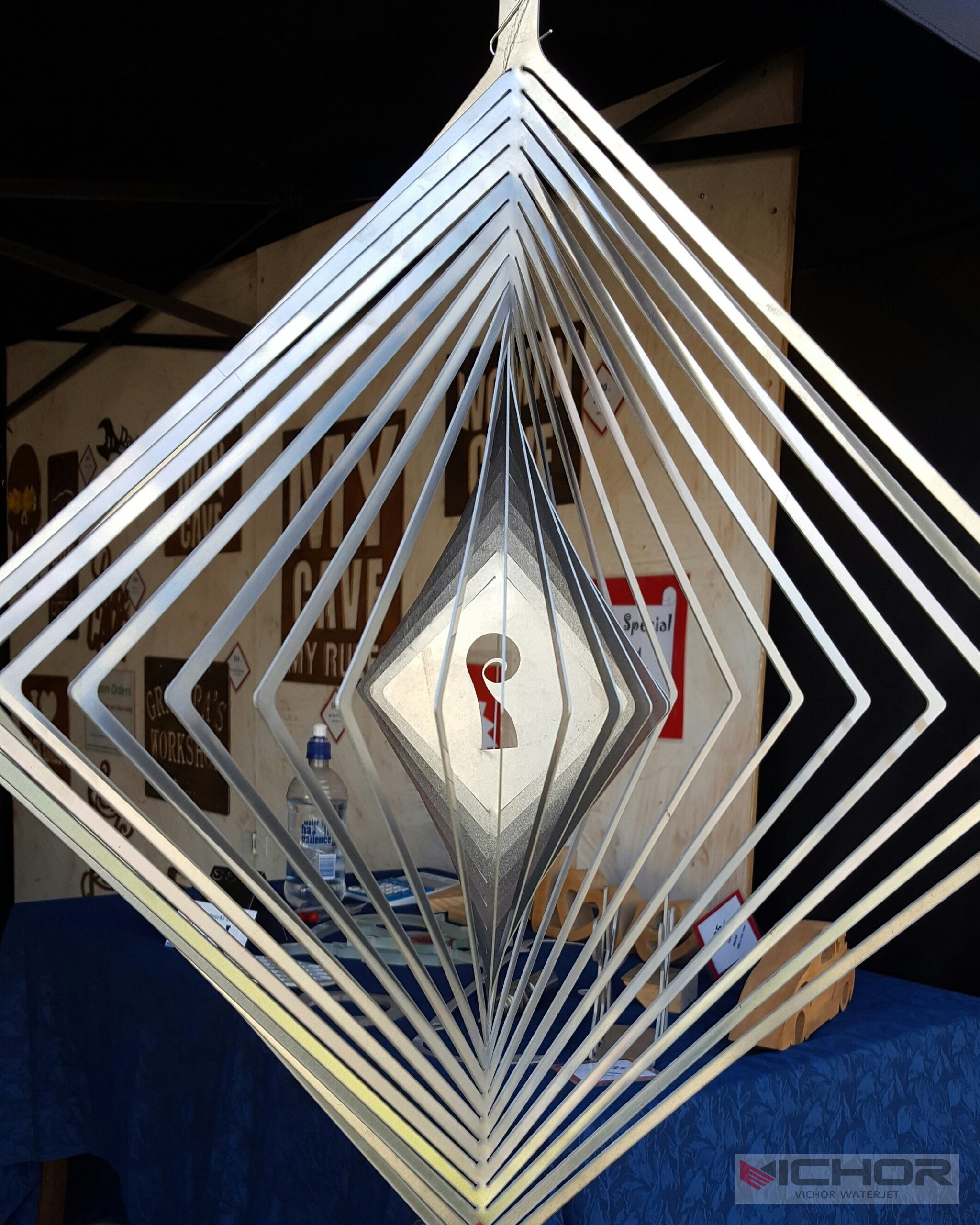

Complex Patterns: Creating intricate mosaics, logos, or custom inlays requires pieces that fit together perfectly. A water jet can produce curves, sharp angles, and detailed cutouts that would be impossible with a manual tile saw.

Tight Tolerances: For installations around plumbing fixtures, electrical outlets, or custom cabinetry, a cut must be exact. The water jet eliminates the guesswork and manual errors associated with traditional nibblers or saws.

Repetition: If a project requires multiple identical complex pieces, the CNC-driven water jet can replicate the same cut hundreds of times with zero deviation, ensuring consistency across the entire installation.

This level of accuracy ensures that every piece of tile fits perfectly the first time, reducing dry-fitting time and ensuring a flawless final result.

Achieving a Chip-Free and Clean Finish

One of the most significant frustrations when cutting hard, brittle materials like porcelain is chipping. The mechanical force and vibration from a diamond blade can cause micro-fractures and break away the delicate glazed surface, ruining the tile’s appearance and edge quality.

Water jet cutting porcelain tile is a cold-cutting process. It does not generate heat, which is a primary cause of thermal stress and cracking in other methods. The abrasive water stream erodes the material at a microscopic level without applying lateral force or vibration. This results in a smooth, clean edge that is virtually free of chips and fractures. The edge quality is superior, often requiring minimal to no polishing, which preserves the integrity and beauty of the tile’s surface right to the very edge. This is especially important for tiles with a rectified edge (precisely ground) that are meant to be installed with very thin grout lines.

Unlocking Unlimited Design Possibilities and Customization

The precision and cleanliness of the water jet process directly translate into boundless creative freedom. It transforms porcelain tile from a standard building material into a medium for artistic expression.

Custom Inlays: Homeowners and designers can create stunning feature walls or floors by combining different colored tiles into a seamless, custom pattern. The water jet can cut complementary pieces from different tiles that lock together like a puzzle.

Detailed Artistic Pieces: From company logos in a commercial lobby to a family crest in a residential foyer, a water jet can translate any vector-based image into a cut path on a tile.

Complex Shapes: Instead of being limited to standard squares and rectangles, tiles can be cut into circles, waves, hexagons, or entirely organic, free-form shapes.

Vent Covers and Outlets: Instead of awkwardly cutting around air vents or electrical outlets, a tile can be precisely cut to incorporate these elements neatly, making them a deliberate part of the design rather than an afterthought.

This ability to customize is a game-changer, allowing for truly unique and personalized spaces that reflect the owner’s specific taste and vision.

The Material Efficiency and Waste Reduction Advantage

Porcelain tile is a significant investment, and wasted material due to cutting errors can drastically increase the cost of a project. Traditional cutting methods, especially for complex shapes, often result in a high percentage of breakage and off-cuts that are too small to use.

Water jet cutting porcelain tile is incredibly efficient. The CNC software allows for nesting, which is the process of arranging multiple cut paths from a digital design onto a tile slab in the most optimal way to minimize waste. The narrow kerf (the width of the cut) of a water jet stream—only about 0.04 inches (1 mm)—means significantly less material is turned into dust compared to the wider cut of a diamond blade. This efficient use of material not only saves money on the cost of tiles but also aligns with sustainable building practices by reducing waste sent to landfills.

Versatility Across Tile Types and Thicknesses

The composition and thickness of porcelain tile can vary widely, from thin 3mm panels used in renovations to thick 20mm (or more) slabs for countertops. A common challenge is finding one tool that can handle this entire range effectively.

A water jet cutter is exceptionally versatile. The pressure of the water and the amount of abrasive can be calibrated to cut through virtually any thickness of porcelain tile without a loss in quality. It handles:

Thin Tiles: Without the risk of vibration causing breakage.

Thick Slabs: Capable of cutting through 3-inch (75mm) thick materials, making it perfect for countertops and heavy-duty commercial floors.

Textured Surfaces: Tiles with heavy texture or rippled surfaces are difficult to cut with a blade because the uneven surface can cause the blade to chatter and skip. A water jet, having no physical contact until the stream hits the material, glides over textures without issue, ensuring a consistent cut from start to finish.

This “one-tool-fits-all” capability makes it an incredibly valuable asset for fabricators who work with a diverse range of materials.

The Safety and Environmental Benefits

Compared to many industrial cutting processes, water jet cutting porcelain tile offers a notably safer and cleaner working environment.

No Heat or Harmful Fumes: Since it’s a cold process, there is no risk of burning the material or generating hazardous dust. While cutting does produce a slurry (a mixture of water and abrasive garnet), it is not airborne like the silica dust created by dry cutting. Silica dust is a serious health hazard when inhaled, leading to respiratory illnesses like silicosis. Water jet cutting significantly mitigates this risk.

Reduced Physical Risk: The cutting process is fully enclosed during operation, protecting the operator from the high-pressure stream. There are no exposed sharp blades to handle, reducing the risk of laceration injuries.

Eco-Friendly: The primary abrasive used, garnet, is a non-toxic, natural mineral. The water used in the process can often be recycled and filtered within the machine’s system. The lack of chemical additives or oils makes the process more environmentally friendly than many alternatives.

Integrating Water Jet Cutting into Your Project Workflow

Understanding how to leverage this technology is key to a successful project. The process typically involves:

Design: Creating or obtaining a vector file (e.g., .DXF or .DWG) of the desired shape.

Programming: The file is imported into the water jet’s CNC software where the cutting path is programmed.

Setup: The porcelain tile is securely placed on the machine’s cutting table.

Execution: The machine executes the cut with precision, guided by the digital file.

Finishing: The cut pieces are removed, cleaned of the abrasive slurry, and are ready for installation, often with no further edge work needed.

For most individuals, this means partnering with a professional fabrication shop that offers water jet cutting porcelain tile services. Providing them with a precise digital design file is the first step to transforming a vision into a tangible, beautifully cut piece of porcelain art.

While traditional tile cutters still have their place for simple, straight cuts, the advantages of water jet cutting porcelain tile for complex, high-end, and custom projects are undeniable. From its surgical precision and chip-free edges to its incredible versatility and material efficiency, this technology solves the biggest challenges associated with working with hard porcelain. It empowers designers, architects, and homeowners to push the boundaries of creativity, ensuring that the final installation is not only structurally sound but also a flawless work of art. For any project that demands perfection beyond the standard square cut, investing in water jet technology is the clear and superior choice.

continue reading

Related Posts

- 1077 words5.4 min read

- 1175 words5.9 min read

- 1255 words6.3 min read