The Ultimate Guide to a Water Jet Cutter for Home Use: 5 Realities You Must Know

The idea of owning a water jet cutter for home use sparks the imagination of DIY enthusiasts, artists, and hobbyists everywhere. Imagine effortlessly slicing through metal, stone, tile, and glass in your garage or workshop, creating intricate designs with cold, precise, and burr-free edges. It sounds like a futuristic dream, something reserved for heavy industrial factories.

However, the landscape of technology is constantly shifting. What was once an impossible tool for the average person is now—cautiously—entering the realm of possibility. But is a water jet cutter for home use a practical reality in 2024, or is it still a pipe dream? This ultimate guide cuts through the hype and explores five critical aspects you must understand, covering the exciting potential and the hard, cold realities of bringing this powerful technology into your home.

The Reality Check: Is a Home Water Jet Cutter Even Practical?

Before diving into specifications and models, it’s crucial to address the elephant in the room: practicality. A traditional industrial waterjet is a beast. It requires a massive amount of space, three-phase power, a dedicated water supply and drain, and generates significant noise and mess. This is clearly incompatible with a water jet cutter for home use.

The game-changer has been the development of desktop waterjet systems. Pioneered by companies like WAZER, these machines are explicitly engineered for the prosumer and small business market. They are dramatically smaller, often the size of a large desktop CNC router or a washer/dryer unit. They run on standard 110V/220V household electricity and use a closed-loop filtration system to minimize water consumption and mess.

So, the answer is a qualified yes. A water jet cutter for home use is now a practical reality, but with major caveats. It’s not for the casual weekend warrior due to its cost and complexity. It’s aimed squarely at:

Serious artists and sculptors working with metal, stone, or glass.

Small-scale custom fabricators and inventors running a business from a home workshop.

Dedicated hobbyists for whom this is a primary passion and investment.

It is not a tool you buy on a whim; it’s a significant commitment of space, budget, and learning.

Inside a Desktop Water Jet Cutter: How It Works and Key Specifications

Understanding the core technology is key to evaluating any machine. The fundamental principle of eroding material with a high-pressure stream of water and abrasive remains the same, but the execution is scaled down for a water jet cutter for home use.

Key Components Simplified:

The Pump: Instead of a massive 60,000 PSI intensifier pump, desktop models use a simpler, quieter, and more compact direct-drive or pressure multiplier pump. They typically operate in the 40,000 to 60,000 PSI range, which is still more than enough power to cut through most materials a home user would need, just at slower speeds than industrial counterparts.

The Cutting Bed and Motion System: The machine is built on a sturdy, precision-milled aluminum or steel frame. A gantry system with accurate stepper or servo motors moves the cutting head on the X and Y axes based on digital instructions.

The Closed-Loop Water System: This is a critical feature for a water jet cutter for home use. Instead of constantly draining water, the machine pumps it from a main tank, through the pump and head, and into a “catch tank.” The water is then filtered and recirculated back to the main tank. This drastically reduces water consumption, needing only a top-up now and then due to evaporation.

Abrasive Delivery System: A hopper holds the garnet abrasive, which is metered into the cutting head via a precise feed system.

Key Specifications to Compare:

Work Envelope: The maximum size of material you can cut. Desktop models range from about 12″ x 12″ to 24″ x 48″. This is a primary limiting factor.

Max Pump Pressure: Higher pressure generally allows for faster cutting speeds and the ability to tackle thicker materials.

Positioning Accuracy and Repeatability: Measured in thousandths of an inch (±0.001″ or similar), this defines how precise your cuts will be.

Materials and Max Thickness: Every machine will have a chart specifying its performance (cut speed) on various materials (e.g., aluminum, steel, stone, titanium) at different thicknesses.

The True Cost of Ownership: Far More Than the Sticker Price

This is the most critical section for anyone considering a water jet cutter for home use. The initial purchase price is just the beginning.

1. Initial Investment:

Desktop water jets start at around $10,000 and can go up to $25,000+ for more capable models. This immediately places them in a different league than most home workshop tools like 3D printers or laser cutters.

2. Consumables (The Ongoing Cost):

This is where many beginners get a shock. The true cost of running a waterjet is in its consumables.

Abrasive Garnet: You will go through garnet quickly. It’s a continuous consumable, much like ink in a printer, but far messier. A 50lb bag costs between $30-$60, and you might use multiple bags for a large project.

Orifice and Nozzle: The tiny sapphire orifice and tungsten carbide mixing tube (nozzle) are wear items. Their lifespan depends on usage and water quality but expect to replace them every 20-50 cutting hours. Each can cost $100-$200.

High-Pressure Seals: The pump has seals that will need replacement after several hundred hours of use. This is a more involved maintenance task.

Water Filter Cartridges: The closed-loop system uses filters to keep the water clean, and these need regular replacement.

3. Maintenance:

These are precision machines. You will need to perform regular maintenance: cleaning the tank of sludge (a mix of spent abrasive and cut material), checking for leaks, replacing filters, and ensuring the abrasive feed is not clogged. It is a dirty, time-consuming process.

H2: Safety, Setup, and the Home Environment: A Major Consideration

You cannot simply plug a water jet cutter for home use into any outlet and start cutting. The setup requirements are substantial.

Space: You need a dedicated, well-ventilated space like a garage or a sturdy outbuilding. The machine itself, its water tanks, and the material handling require a significant footprint.

Power: Most desktop models require a dedicated 220V outlet, similar to a welder or a large tablesaw.

Noise: While quieter than an industrial machine, it is still very loud. Ear protection is mandatory for anyone in the room while it’s operating.

Mess and Sludge: Waterjet cutting is inherently messy. Fine abrasive dust and the wet sludge of cut material (known as “swarf”) will get everywhere if not contained. You will be dealing with a gritty, watery waste product that must be disposed of properly—it cannot go down a household drain.

Safety: The cutting stream is invisible and can cause severe injury in an instant. The machine must be operated with all safety guards in place. The high-pressure system also presents a risk of leaks, which can damage your surroundings.

Is It Right For You? Material Projects and Alternatives

Finally, you must honestly assess your needs. A water jet cutter for home use excels at cutting hard, thick materials that other desktop tools cannot handle.

Ideal Projects for a Home Waterjet:

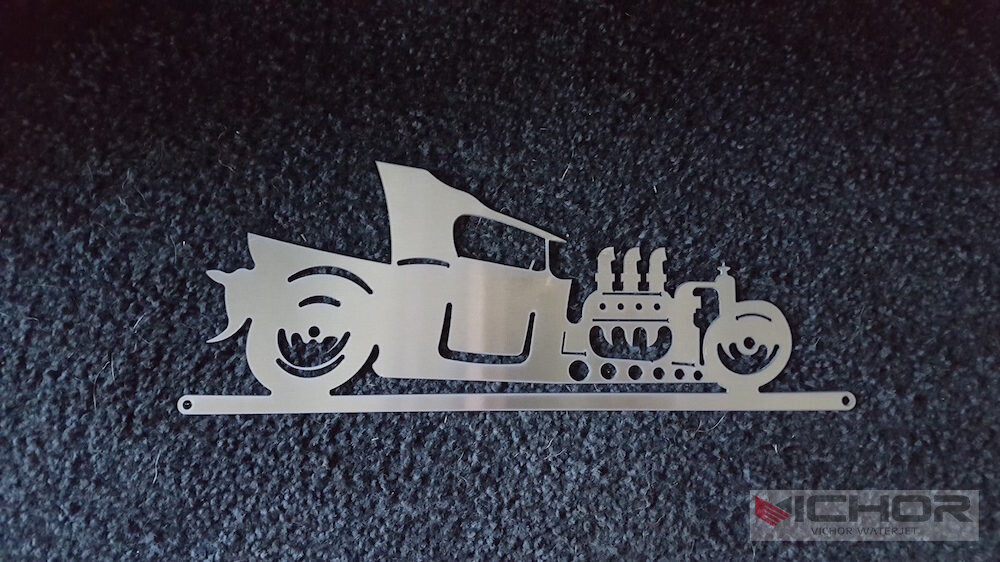

Creating intricate custom metal art and signs.

Cutting precise parts for custom motorcycles, bikes, or cars.

Fabricating one-off prototypes from aluminum or stainless steel.

Making custom stone, marble, or glass tiles and inlays.

Crafting detailed parts from composites like carbon fiber.

Before You Buy, Consider These Alternatives:

For thin metals/plastics: A fiber laser cutter is faster, cleaner, and has lower consumable costs, but it cannot cut non-metals effectively and is a major fire hazard.

For wood, plastics, and soft materials: A CNC router is a far more affordable and cleaner option.

For general metal shaping: An angle grinder, bandsaw, or plasma cutter (for conductive metals only) are vastly cheaper, though less precise.

The dream of a water jet cutter for home use is now a reality, but it remains a niche, high-end, and demanding tool. It is not for everyone. It is a serious capital investment with significant ongoing costs and maintenance demands. However, for the right person—a serious artist, a micro-fabricator, or an inventor who needs its unique capability to cut virtually any material with precision—it is an utterly revolutionary technology that can unlock incredible creative potential from the comfort of a home workshop. The key is to go in with your eyes wide open to the realities, costs, and commitment required.

continue reading

Related Posts

- 1216 words6.1 min read

- 1207 words6.1 min read