5 Revolutionary Advantages of a Water CNC Cutting Machine: The Ultimate Guide

In the realm of modern manufacturing and fabrication, precision, versatility, and efficiency are paramount. While lasers, plasma cutters, and traditional milling machines have long been staples on the shop floor, one technology stands out for its unique ability to cut almost any material without heat or mechanical stress: the Water CNC Cutting Machine. Often referred to as a waterjet cutter, this remarkable tool combines the ancient power of water with sophisticated computer numerical control (CNC) to create one of the most flexible cutting systems available today. But what exactly is it, and why should you consider it for your operation? This in-depth guide explores the five key advantages of using a Water CNC Cutting Machine, delving into how it works, its vast applications, and how it compares to other technologies.

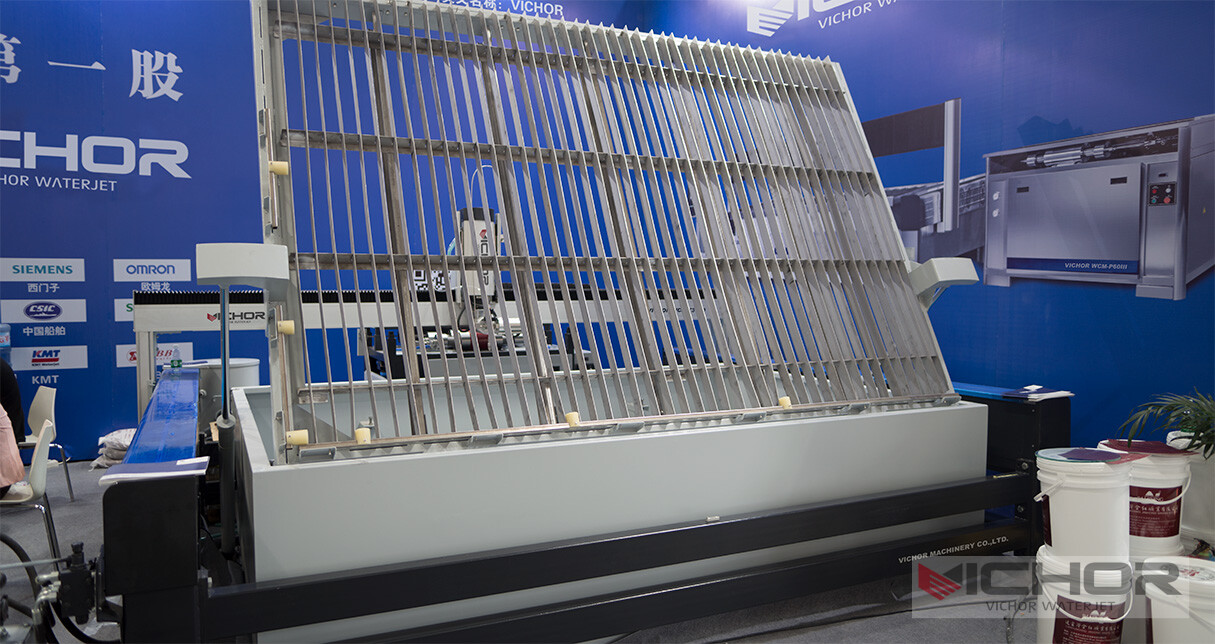

What is a Water CNC Cutting Machine? The Fusion of Nature and Technology

A Water CNC Cutting Machine is a computer-controlled industrial tool that uses a highly pressurized stream of water, often mixed with an abrasive substance, to cut through materials. The “CNC” aspect is crucial—it means the machine’s movement is directed by a computer program following a digital design (like a CAD file), allowing for incredibly precise and repeatable cuts.

The process begins with a high-pressure pump, typically an intensifier pump, that pressurizes ordinary tap water to extreme levels, ranging from 60,000 to 90,000 pounds per square inch (PSI). This ultra-high-pressure water is then forced through a small, precision orifice—usually made of sapphire or diamond—creating a thin, coherent stream moving at speeds up to three times the speed of sound. For cutting hard materials like metal, stone, or glass, a granular abrasive (such as garnet) is sucked into the stream via a venturi effect in a mixing chamber, creating a potent erosive beam that micromachines the material. The entire cutting head is mounted on a sturdy gantry system that moves along the X and Y axes with extreme accuracy, following the path dictated by the CNC software.

Advantage 1: Unmatched Versatility and Material Compatibility

Perhaps the most significant benefit of a Water CNC Cutting Machine is its breathtaking versatility. It is truly a “one-stop-shop” cutting solution.

Cuts Virtually Any Material: From the hardest known substances to the softest and most delicate, a waterjet can handle it. This includes metals (titanium, steel, aluminum, brass), stone and tile, glass, composites, rubber, plastics, foam, leather, and even food products.

No Material Limitations: Unlike laser cutters, which struggle with reflective materials (copper, brass) or materials that emit toxic fumes when vaporized (like PVC), a waterjet has no such restrictions. It can cut reflective materials effortlessly and is a cold process, so there is no toxic gas emission from the material itself.

Variable Thickness: The same machine can cut thin, delicate sheets of paper or foil and then be programmed to slice through 8-inch-thick blocks of titanium or granite without changing the tooling.

This unparalleled material compatibility makes the Water CNC Cutting Machine an invaluable asset for job shops and manufacturers who work with a diverse range of products and don’t want to invest in multiple, dedicated cutting systems.

Advantage 2: The Cold Cutting Process – Zero Heat-Affected Zone (HAZ)

Heat is the enemy of material integrity in many cutting processes. Lasers and plasma cutters use intense heat to melt or vaporize material, which creates a Heat-Affected Zone (HAZ) along the edge of the cut.

What is HAZ? The HAZ is an area where the material’s metallurgical properties are altered by the extreme heat. This can lead to hardening, warping, micro-cracking, or changes in temper, which often requires secondary processing like grinding or annealing to correct.

The Waterjet Solution: A Water CNC Cutting Machine is a cold-cutting process. It erodes material through mechanical abrasion, not thermal energy. This means there is absolutely no heat input into the part being cut.

Preserves Material Properties: The absence of HAZ ensures that the material retains its original strength, hardness, and structure right up to the cut edge. This is a critical advantage for aerospace components, tool steel, and heat-sensitive metals where any structural compromise is unacceptable.

Advantage 3: Superior Precision and Minimal Kerf

CNC technology brings exceptional accuracy to waterjet cutting, making it suitable for highly complex and detailed work.

Tight Tolerances: A modern Water CNC Cutting Machine can hold tolerances as tight as ± 0.003 inches (± 0.076 mm) or better, depending on the material and thickness. This allows for the creation of intricate patterns, sharp corners, and fine details that would be difficult or impossible with other methods.

Small Kerf Width: The kerf (the width of the cut) is determined by the diameter of the stream, typically ranging from 0.020″ to 0.050″ (0.5mm to 1.3mm). This is narrower than a plasma cutter and comparable to many lasers. A small kerf means less material waste, which is a major cost-saving factor when working with expensive materials like titanium or marble.

5-Axis Capability: Advanced waterjet systems can be equipped with 5-axis cutting heads. This allows the nozzle to tilt and cut beveled edges on thick material without taper (a common issue known as the “V-shaped kerf”) and create complex 3D shapes, further expanding its capabilities beyond flat sheet cutting.

Advantage 4: Environmental Benefits and Operational Safety

In an era of increasing environmental consciousness, the Water CNC Cutting Machine offers several green and safe advantages.

Reduced Hazardous Waste: The process does not produce hazardous fumes or vapors. The primary waste is a slurry of water and spent abrasive mixed with fine particles of the cut material. This slurry is non-toxic and can often be separated and disposed of easily, with the water being recycled back into the system.

Energy Efficiency: While the intensifier pump requires significant power, the overall energy consumption for cutting a wide variety of materials can be lower than maintaining multiple dedicated machines (e.g., a laser for thin metal, a router for composites, a saw for stone).

Safety: The process is inherently spark-free, making it safe for use in environments where flammable gases or dust may be present. The cutting action is also contained within a water-filled tank, which significantly reduces noise levels and contains splash and debris.

Advantage 5: Speed, Efficiency, and Ease of Use

For many applications, a waterjet offers a perfect balance of speed, setup time, and operational simplicity.

Rapid Prototyping and Production: There is no need for custom tooling, molds, or dies. A designer can create a part in CAD, generate the toolpath, and begin cutting within minutes. This makes it ideal for both rapid prototyping and short-to-medium production runs, drastically reducing lead times.

Nesting Software: Advanced CNC software allows for efficient nesting of parts, automatically arranging them on a sheet of material to minimize waste. This maximizes material yield and improves overall job efficiency.

Minimal Setup and Operation: Once the material is placed on the table and the program is loaded, the machine can largely run unattended. Modern systems are designed for reliability and ease of maintenance, ensuring high uptime and productivity.

Key Applications Across Industries

The unique combination of advantages makes the Water CNC Cutting Machine indispensable across a wide spectrum of industries:

Aerospace & Automotive: Cutting composites, titanium alloys, aluminum panels, insulation, gaskets, and custom parts without compromising material strength.

Architecture & Art: Creating intricate designs in stone, tile, and metal for decorative panels, sculptures, signage, and countertops.

Manufacturing: Producing parts for machinery, tools, and consumer products from a vast array of materials.

Food Industry: Using pure water jets (without abrasive) to portion frozen foods, cut cakes, slice fish, and more—hygienically and without crushing or bruising.

Waterjet vs. Laser vs. Plasma: Choosing the Right Tool

While superior in versatility, it’s important to understand where a waterjet stands against its competitors:

Laser: Faster on thin metals and offers excellent edge quality on certain materials, but limited by material type and creates HAZ.

Plasma: Faster and cheaper for thick conductive metals, but with a much larger kerf, significant HAZ, and lower precision.

Waterjet: The best all-rounder. It may not always be the absolute fastest, but it is the only technology that can cut such a wide range of materials厚度 with high precision and no thermal damage.

The Water CNC Cutting Machine is more than just a tool; it is a transformative manufacturing solution. Its five revolutionary advantages—unmatched versatility, cold-cutting with no HAZ, high precision, environmental friendliness, and operational efficiency—make it a compelling investment for any serious fabricator. If your work involves a diverse mix of materials, requires absolute preservation of material properties, or demands complex shapes with tight tolerances, a waterjet is not just an option; it is the ultimate cutting technology capable of unlocking new levels of creativity and productivity in your workshop.

continue reading

Related Posts

- 1077 words5.4 min read

- 1175 words5.9 min read

- 1255 words6.3 min read