Mobile Water Jet Cutting Services: Revolutionizing On-Site Industrial Fabrication

In today’s demanding industrial landscape, the need for precision cutting solutions that can travel directly to the job site is paramount. Enter Mobile Water Jet Cutting Services – a game-changing innovation that brings the unparalleled versatility and power of waterjet technology directly to your location, eliminating the logistical headaches and costs associated with transporting large or complex workpieces. This comprehensive guide explores how these mobile services are transforming industries by delivering high-precision, cold-cutting capabilities wherever they are needed.

What Are Mobile Water Jet Cutting Services? (The Core Concept)

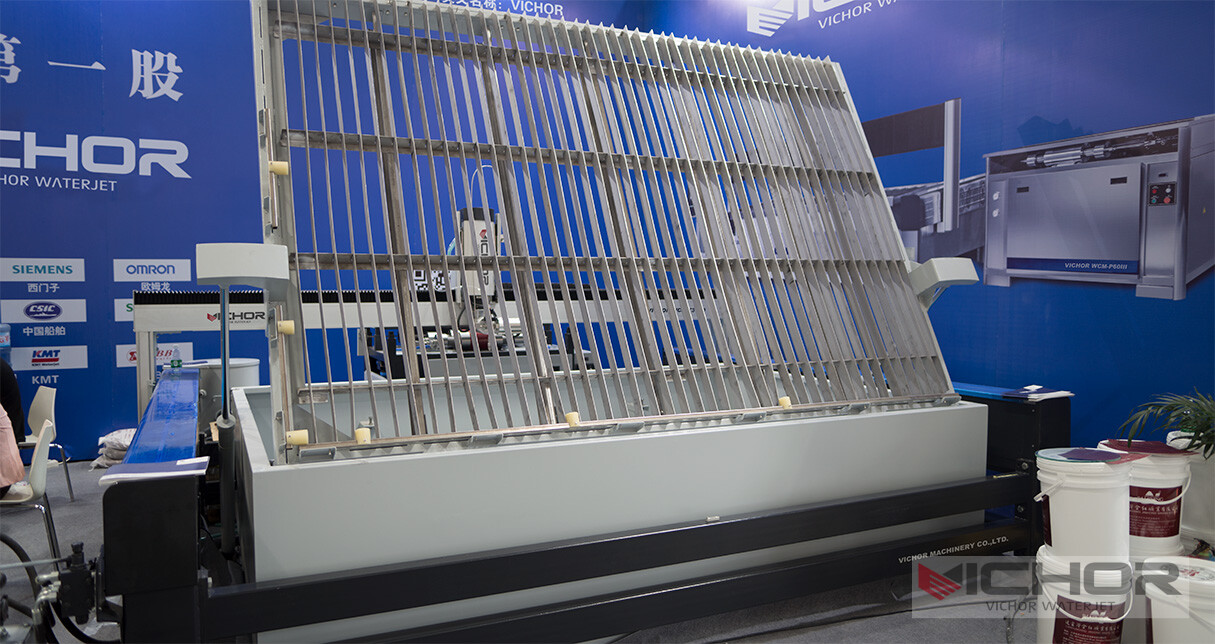

Unlike traditional waterjet cutting confined to fixed workshops, mobile water jet cutting services utilize specialized trailers or trucks equipped with fully functional, high-pressure waterjet cutting systems. These self-contained units house the intensifier pump, abrasive delivery system, cutting table or structure, and sophisticated CNC controls, all designed for transportation and rapid setup on-site. The core principle remains the same as stationary waterjets: a supersonic stream of water, often mixed with abrasive garnet, erodes material with extreme precision and without generating heat. The revolutionary aspect lies in bringing this capability to the project – whether it’s a construction site, a factory floor, a shipyard, an offshore platform, or a decommissioning project. This inherent mobility defines the unique value proposition of on-site waterjet cutting solutions.

The Compelling Advantages of Choosing Mobile Cutting

Opting for mobile water jet cutting services offers a multitude of significant benefits over traditional fabrication methods or transporting parts to a fixed shop:

Eliminate Transport Costs and Risks: Moving large, heavy, or delicate materials is expensive, logistically complex, and risks damage. Mobile services remove this burden entirely.

Minimize Project Downtime: On-site cutting drastically reduces or eliminates the downtime associated with disassembling equipment, removing components for off-site work, and reinstalling them. Cutting can often be performed while adjacent operations continue.

Unmatched Versatility On-Demand: Need to modify an existing structure, create an opening in a pressure vessel, or cut intricate shapes in a large assembly? Mobile waterjet cutting provides instant access to a tool capable of handling virtually any material and complex geometry right where the need arises.

Cold Cutting Process: The waterjet process generates no heat-affected zone (HAZ). This is absolutely critical when working near sensitive components, hazardous materials, or heat-treated metals where thermal distortion or structural weakening is unacceptable. It also prevents material hardening and eliminates fumes or toxic gases produced by thermal cutting.

Material Agnosticism: From 10-inch thick steel and exotic alloys (titanium, Inconel) to stone, glass, composites, rubber, and food products, mobile waterjet services cut them all effectively without changing tools or processes.

High Precision and Edge Quality: CNC-controlled mobile water jet cutting delivers exceptional accuracy (±0.003″ to ±0.005″ is typical) and produces smooth edges, often requiring little to no secondary finishing.

Enhanced Safety: The cold-cutting nature reduces fire hazards significantly, especially crucial in volatile environments like refineries, chemical plants, or confined spaces. The mobile unit itself incorporates safety features for on-site operation.

Diverse Applications: Where Mobile Waterjet Excels

The flexibility of mobile water jet cutting services makes them indispensable across a wide spectrum of industries and scenarios:

Construction & Infrastructure: Modifying structural steel beams on-site, cutting precise openings in concrete or rebar, creating custom stone or tile features during building installation, tunnel liner plate modification.

Shipbuilding & Repair (Shipyards & Dry Docks): Cutting hull plates, decks, and bulkheads; modifying existing ship structures; cutting pipe and flange faces; propeller cutouts; removing damaged sections without thermal distortion affecting surrounding hull integrity. Mobile waterjet services are essential for dry dock efficiency.

Oil & Gas (Platforms, Refineries, Pipelines): Cutting pipe in-situ, modifying pressure vessels and tanks (especially crucial due to no HAZ), cutting wellheads, creating hot taps, decommissioning equipment safely in hazardous areas. The cold-cutting capability is non-negotiable here.

Power Generation (Nuclear, Fossil, Renewable): Maintenance and modification of turbines, boilers, heat exchangers, and containment structures where thermal cutting is prohibited. Cutting composite wind turbine blades on-site.

Aerospace & Defense: On-site modification or repair of airframe components, cutting composite structures, removing damaged sections from large assemblies without disassembly. Precision is paramount.

Heavy Manufacturing & Fabrication: Modifying large machinery bases, frames, or assemblies that cannot be moved easily. Creating custom parts or prototypes directly on the factory floor.

Decommissioning & Dismantling: Safely and precisely cutting apart large structures, pressure vessels, reactors, or equipment for removal and recycling, especially in confined or sensitive areas.

Mining & Heavy Equipment: Repairing and modifying large mining equipment, crushers, and haul truck bodies on-site.

The Mobile Operation: Logistics and Site Requirements

Understanding how mobile water jet cutting services operate logistically is key:

The Mobile Unit: Typically housed in a large, climate-controlled trailer or truck. It contains the high-pressure pump (often 60,000-90,000+ PSI), water filtration/purification system, abrasive hopper and metering system, cutting head manipulator (gantry, articulated arm, or track system), CNC controller, and often a cutting table or support structure.

Site Setup: Requires a reasonably level, stable surface for the trailer/truck. Access for the vehicle is crucial. Setup usually takes several hours once positioned.

Utilities:

Power: High electrical demand is the primary requirement. Units typically need a robust 3-phase power supply (e.g., 480V, 100-200+ amps), often provided by a large generator (which the service may bring) or connected to the site’s main power.

Water: Requires a clean water source (municipal, filtered well water) for filling the system’s reservoir. Water is recycled internally during cutting, but initial fill and occasional top-ups are needed. Flow rate demand is moderate.

Drainage: A containment area or plan for the spent water/abrasive slurry is essential. This slurry is non-hazardous but requires proper collection and disposal, often managed by the mobile service provider.

Abrasive Supply: Garnet abrasive is consumed during cutting. The mobile unit carries a supply, but large projects may require additional abrasive delivery to the site.

Operator Expertise: Highly skilled technicians operate the complex equipment and program the cuts, ensuring safety and precision on-site.

Selecting the Right Mobile Water Jet Cutting Service Provider

Choosing a reliable mobile water jet cutting service is critical for project success. Consider these factors:

Equipment Capability: Does their mobile unit have sufficient pressure, cutting envelope size (X, Y, Z travel), and precision for your specific job? Can it handle the material type and thickness?

Experience & Expertise: Look for proven experience in your industry and with similar applications. Operator skill is paramount for complex on-site cutting. Ask for case studies or references.

Mobility & Reach: Confirm they service your geographic location and can mobilize to your site within your timeframe.

Power Solutions: Clarify how they handle power requirements – do they provide large generators, or must you supply the specified 3-phase power?

Slurry Management: Understand their process for containing, removing, and disposing of the abrasive slurry. This is a key logistical aspect.

Safety Record & Protocols: Rigorous safety procedures are non-negotiable for on-site industrial work. Inquire about their safety programs, certifications (like OSHA compliance), and site-specific safety planning.

Project Management & Communication: Effective communication and clear project planning are essential for coordinating the mobile service arrival, setup, cutting, and demobilization seamlessly with your site operations.

Cost Competitiveness & Transparency: Obtain detailed quotes that outline setup, cutting time, abrasive costs, consumables, and any ancillary fees (like slurry disposal or generator fuel).

Mobile Water Jet Cutting Services represent a significant leap forward in industrial flexibility and efficiency. By eliminating the constraints of fixed workshop locations and overcoming the challenges of moving massive components, they unlock new possibilities for fabrication, modification, maintenance, and repair across countless sectors. The combination of extreme versatility (cutting virtually any material), the critical advantage of cold cutting (no HAZ), and the delivery of high precision directly to the point of need makes this service an invaluable strategic asset.

As industries continue to seek ways to reduce downtime, lower costs, enhance safety, and tackle complex projects in challenging environments, the demand for reliable, high-performance mobile water jet cutting services will only intensify. They are no longer just a niche offering but an essential, productivity-boosting solution for forward-thinking businesses aiming to maintain a competitive edge through innovative on-site manufacturing capabilities. When faced with large-scale, immobile, or heat-sensitive cutting challenges, the answer increasingly lies in calling upon the power and precision of a mobile water jet cutting service.

continue reading

Related Posts

- 1077 words5.4 min read

- 1175 words5.9 min read

- 1255 words6.3 min read