The 2025 Guide to 4x8 Waterjet Table Price: Breaking Down Costs & Key Factors

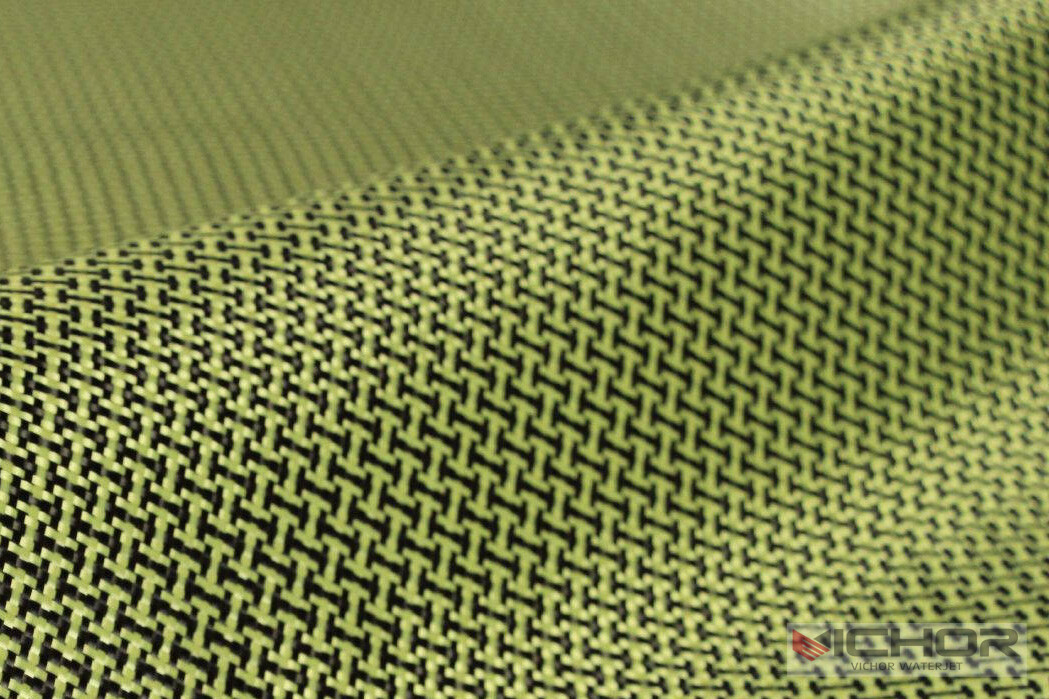

Understanding the 4×8 waterjet table price is a critical step for any shop considering this powerful, versatile cutting technology. A 4×8 foot cutting bed is arguably the most popular size globally, offering an excellent balance of capability for sheet materials (like metal, stone, glass, composites) and manageable footprint. However, the price tag for such a machine is far from simple. It’s not a single number but a spectrum influenced by numerous technical and commercial factors. This guide delves deep into the key elements shaping the 4×8 waterjet table price, empowering you to budget effectively and make an informed investment.

Why Understanding the 4×8 Waterjet Table Price is Crucial

Purchasing a waterjet represents a significant capital investment. Accurately forecasting the 4×8 waterjet table price range relevant to your specific needs prevents sticker shock and ensures you secure a machine that delivers the required performance and return on investment. Underestimating costs can lead to budget overruns, while overestimating might cause you to overlook viable options. Knowing the components that drive price allows for meaningful comparisons between manufacturers and configurations, ensuring you pay for the capabilities you truly need, not unnecessary extras or, conversely, sacrifice critical features for a lower upfront cost that costs more in the long run.

Factor 1 – Machine Base Price & Core Configuration

The foundation of the 4×8 waterjet table price is the base machine itself, encompassing the structural frame, motion system (gantry, drives, rails), cutting table (slats or tank), and basic control hardware.

Entry-Level Systems: Starting around $150,000 – $220,000 USD, these typically feature simpler linear motion systems (possibly belt-driven or basic rack-and-pinion), manual slat adjustment, a basic water tank, and a standard industrial PC-based control. They target shops needing reliable cutting for less demanding materials and tolerances.

Mid-Range Systems: Ranging from $220,000 – $350,000 USD, this tier offers significant upgrades. Expect precision ground rails, high-torque servo motors, robust gear rack and pinion or linear motor drives, automatic slat positioning, larger capacity water tanks with filtration, and more sophisticated control systems with better software integration. This is the most common range for general fabrication and job shops.

High-Precision/Industrial Systems: Prices climb from $350,000 – $500,000+ USD for machines built for heavy-duty, high-volume, high-accuracy cutting. Features include ultra-precise linear motor drives, granite or polymer concrete bases for superior damping and thermal stability, advanced dynamic height control (DHC) systems integrated from the start, premium linear guides, and industrial-grade CNC controls designed for seamless factory integration and minimal downtime.

The core build quality, rigidity, and precision of the motion system directly impact longevity, achievable accuracy, and cut quality, heavily influencing the 4×8 waterjet table price.

Factor 2 – Pump Power & Technology: The Heart of the Cost

The high-pressure pump is arguably the single most significant cost driver and performance determinant, dramatically affecting the overall 4×8 waterjet table price. Pump power is measured in Horsepower (HP) or kilowatts (kW), and the technology type is crucial:

Intensifier Pumps:

Technology: Use hydraulic oil to drive a piston that intensifies water pressure. Operate in a “ram” cycle (pressure builds, cuts, releases, repeats).

Cost: Generally offer the lowest initial purchase price within a given HP range. Entry-level pumps (e.g., 30-50HP) might add $40k-$70k to the base machine cost. Higher HP intensifiers (60-100HP) can add $70k-$150k+.

Pros: Proven technology, robust, handle abrasive cutting well.

Cons: Pressure fluctuations during the ram cycle, slightly higher noise/vibration, potentially higher long-term maintenance costs for hydraulic components.

Direct Drive Pumps:

Technology: Use a large electric motor coupled directly to a crankshaft driving multiple plungers. Deliver constant, ripple-free pressure.

Cost: Command a significant premium over intensifiers. Expect to add $70,000 – $150,000+ USD for pumps in the 50-100HP range. High-horsepower direct drives (100HP+) can push this add-on cost well beyond $200k.

Pros: Smoother cut quality (especially on thick materials and delicate edges), constant pressure improves orifice and mixing tube life, generally quieter, potentially lower long-term maintenance (no hydraulics).

Cons: Higher upfront price, more complex electronics.

Pump HP Impact: Within each technology type, higher HP pumps cost significantly more. A 100HP pump, whether intensifier or direct drive, will cost substantially more than a 50HP pump from the same manufacturer. Higher HP enables faster cutting speeds, especially on thicker materials, and the ability to run multiple cutting heads efficiently. The pump choice alone can easily swing the total 4×8 waterjet table price by $50,000 to $150,000 or more.

Factor 3 – Cutting Head Configuration & Complexity

The number and sophistication of cutting heads directly add to the 4×8 waterjet table price.

Single Cutting Head: The standard and most economical configuration. Sufficient for many shops. Adds the essential components (high-pressure tubing, valve, abrasive delivery system, cutting head assembly).

Multiple Cutting Heads (2, 3, or more): Significantly increases throughput by cutting multiple identical parts simultaneously. However, this adds substantial cost:

Additional Head Hardware: Each head requires its own set of valves, abrasive metering systems, high-pressure plumbing, and the head itself.

Pump Demand: Running multiple heads effectively usually requires a higher HP pump (increasing pump cost).

Control Complexity: The CNC system needs to manage multiple toolpaths and synchronize head movements.

Cost Impact: Adding a second head can increase the machine price by $40,000 – $80,000+ USD. A third head adds another substantial increment. Multi-head systems are powerful but can push the 4×8 waterjet table price well into the $400k-$600k+ range easily.

Dynamic Height Control (DHC): This critical subsystem automatically maintains the optimal standoff distance between the cutting head nozzle and the material surface during cutting, compensating for warped material or tapered cuts. While sometimes standard on higher-end machines, it’s often an option costing $15,000 – $40,000+ USD. Omitting DHC severely limits capability and cut quality but reduces initial price.

Vision Systems/Precision Piercing: Advanced options for automated alignment on pre-marked parts or specialized piercing techniques add further cost.

Factor 4 – Control System & Software Sophistication

The CNC control system and accompanying software suite are the “brains” of the operation and vary significantly in capability and price.

Basic Controls: Offer core functionality for programming and running parts. May require more manual intervention or lack advanced features. Often found on entry-level machines, helping keep the 4×8 waterjet table price lower.

Advanced Industrial Controls (e.g., Siemens, Fanuc, proprietary high-end): Provide superior processing power, reliability, advanced motion control algorithms for smoother cutting and higher accuracy, better user interfaces, and robust connectivity (Ethernet, fieldbus). These add $10,000 – $30,000+ USD.

Software Packages: Beyond basic CAD/CAM:

Nesting Software: Optimizes material usage by arranging parts efficiently on the sheet. Crucial for profitability. Basic nesting might be included; advanced, automated nesting is a costly option.

Simulation & Verification: Visualizes the cutting process and checks for errors before running.

Production Monitoring: Tracks machine utilization, job times, material usage.

Advanced CAM Features: Automatic taper compensation, kerf compensation, specialized cutting modes.

Cost Impact: Comprehensive software suites can add $15,000 – $40,000+ USD to the total 4×8 waterjet table price.

Factor 5 – Brand Reputation, Support & Hidden Costs

The manufacturer’s reputation, build quality, and level of support are intangible factors reflected in the price and impacting long-term value.

Premium Brands (e.g., Flow, Omax, KMT – Hypertherm, Bystronic): Command higher prices due to established reputations for reliability, cutting-edge technology, extensive R&D, and (usually) robust global service and support networks. You pay for peace of mind and minimized downtime. Their 4×8 waterjet table price will typically be at the higher end of the spectrum.

Value/Import Brands: Several manufacturers, particularly from China and other regions, offer machines at significantly lower initial price points (sometimes 20-40% less than premium brands for seemingly similar specs). While quality is improving, potential trade-offs can include less robust construction, lower-grade components, potentially less responsive or localized support, and shorter warranty periods. Thorough due diligence is crucial.

Warranty: Length and coverage terms vary. A comprehensive, longer warranty adds value but may be reflected in the initial price.

Installation & Rigging: Often overlooked! Getting a multi-ton machine into your facility, positioned, and leveled requires specialized riggers. Budget $5,000 – $20,000+ USD, depending on location and facility complexity.

Utilities & Site Preparation:

Electrical: High-power pumps (especially direct drive) require substantial 3-phase power (480V common). Installation/upgrade costs can be $10,000 – $50,000+.

Water: Requires clean, filtered water supply and a drain capable of handling abrasive slurry. Filtration systems might be needed.

Compressed Air: For valve operation and cleaning. Requires dry, clean air.

Flooring: Needs a level, robust concrete pad capable of supporting the machine’s weight (often 15,000+ lbs).

Abrasive & Consumables: Garnet abrasive is a major ongoing cost. Orifice jewels and mixing tubes wear out regularly (especially without DHC). Factor in hundreds to thousands of dollars per month in consumables.

Training: Essential for operators and programmers. Can be included or cost extra ($3,000 – $10,000+).

Service Contracts: Highly recommended to minimize downtime. Annual costs typically range from $10,000 – $25,000+ USD, depending on coverage level and machine complexity.

New vs. Used: Navigating the Price Spectrum

The used market offers potential savings on 4×8 waterjet table price:

Potential Savings: Can be 30-60% less than a comparable new machine. Good option for budget-conscious shops or specific, well-understood needs.

Significant Risks:

Unknown History: Wear and tear, maintenance neglect, hidden damage.

Outdated Technology: Older controls, pump technology, or software lacking modern features.

Limited/No Warranty: Repairs become your immediate responsibility.

Parts Availability: Obsolete components can be difficult and expensive to source.

Lack of Support: Manufacturer may not support older machines; seller support may be limited.

Refurbished/Reconditioned: Offered by some manufacturers or specialized dealers. Machines are disassembled, inspected, worn parts replaced, and tested. Usually come with a limited warranty. Price is higher than “as-is” used but lower than new, offering a middle ground. Expect $100,000 – $300,000+ USD depending on age, spec, and refurbishment level.

Due Diligence is Paramount: Inspection by a qualified technician, verifying hours of operation (on pump and machine), checking maintenance records (if available), and understanding the true condition are essential before buying used.

Making Sense of the 4×8 Waterjet Table Price Range – Key Takeaways

As we’ve explored, the 4×8 waterjet table price is a complex equation. Here’s a summary of realistic total investment ranges for a new machine delivered and installed, reflecting the major factors:

Basic Entry-Level: ~ $200,000 – $300,000 USD

Simple motion system, basic control, lower HP Intensifier Pump (30-50HP), single head, minimal options, limited software. Requires careful consideration of long-term needs.

Mid-Range (Most Common): ~ $300,000 – $450,000 USD

Robust motion system, better control, mid-range HP Pump (50-80HP Intensifier or lower-end Direct Drive), single head, likely includes basic DHC, better software suite. Represents a good balance for many job shops.

High-Performance/Heavy Duty: ~ $450,000 – $600,000+ USD

Precision motion (linear motors), industrial control, high HP Pump (80-100HP+ Direct Drive preferred for quality), potentially 2 heads, advanced DHC, comprehensive software. Built for high throughput, tight tolerances, and demanding materials.

Multi-Head/Ultra-Premium: $600,000 – $1,000,000+ USD

Top-tier components, very high HP Direct Drive pump, 2-3+ cutting heads, all advanced options, maximum automation and software. For high-volume production environments.

Smart Buying Tips for Your 4×8 Waterjet

Define Needs Rigorously: Material types, thicknesses, required tolerances, daily/weekly cutting hours, desired cut quality (edge finish, taper), automation needs. Don’t overbuy, but ensure the machine meets all critical requirements.

Total Cost of Ownership (TCO): Look beyond the sticker price. Factor in installation, utilities, consumables (abrasive, parts), maintenance, training, software updates, and potential downtime costs. A slightly higher initial price with lower operating costs or higher reliability often wins long-term.

Get Detailed Quotes: Ensure quotes include everything: machine specs, pump type/HP, head count, DHC, control, software, warranty, delivery terms (FOB?), installation support scope. Compare apples-to-apples.

Demand Demonstrations: Cut samples of your materials on prospective machines. Evaluate cut speed, quality, edge finish, taper, ease of use, and software workflow.

Investigate Support: Research the manufacturer/dealer’s reputation for service response time, parts availability, and technical expertise in your region. Strong support is invaluable.

Consider Financing: Explore lease options or loans to preserve capital. Tax incentives (like Section 179 in the US) may apply.

Frequently Asked Questions (FAQ) on 4×8 Waterjet Table Price

Q: What is the absolute cheapest 4×8 waterjet table price I can find?

A: Very basic, new entry-level machines from value brands might start around $150,000-$180,000 base price before pump. However, with a minimal pump, installation, and essentials, expect the total outlay to be at least $200,000. Used “as-is” machines can be found below $100,000 but carry high risk.

Q: Is a Direct Drive pump worth the extra cost?

A: It depends. For precision cutting, superior edge quality (especially on thick materials or delicate edges), reduced consumable wear, and potentially lower long-term maintenance (no hydraulics), Direct Drive is often worth the premium for demanding applications. For rougher cuts or budget focus, a high-quality Intensifier can be sufficient.

Q: How much does installation really cost?

A: Budget $10,000 – $30,000 USD realistically. This covers professional rigging, moving, positioning, leveling, and basic utility hookup assistance. Complex site prep (power upgrades, special foundations) adds significantly more.

Q: What are the biggest hidden costs?

A: Site preparation (electrical upgrades!), ongoing garnet abrasive (a major expense), replacement consumables (orifice, mixing tubes, seals), maintenance labor/parts, training, and potential production losses due to downtime if support is poor.

Q: How much should I budget for annual maintenance?

A: At a minimum, budget 3-5% of the machine’s purchase price annually for routine maintenance parts and labor. A full service contract typically costs $10,000 – $25,000+ USD per year but provides predictable costs and faster support.

Navigating the 4×8 waterjet table price landscape requires careful consideration of your specific production needs, a deep dive into the core cost factors (machine build, pump, heads, controls), and a realistic assessment of the total cost of ownership, including installation, operation, and support. While the initial investment is substantial, ranging roughly from $200,000 for a basic setup to well over $600,000 for a high-performance multi-head system, the versatility, precision, and material-cutting capabilities of a 4×8 waterjet deliver significant value for manufacturers across countless industries. By thoroughly understanding what drives the 4×8 waterjet table price and focusing on Total Cost of Ownership, you can make a confident investment that boosts your shop’s capabilities and profitability for years to come. Always prioritize demonstrations and evaluate the manufacturer’s support reputation alongside the quoted price.

continue reading

Related Posts

- 1077 words5.4 min read

- 1175 words5.9 min read

- 1255 words6.3 min read