Water Jet Cut Tiles: Unlocking Precision, Design Freedom & Durability for Modern Spaces

In the world of tile design and installation, achieving intricate patterns, perfect curves, and seamless fits often pushes traditional cutting methods to their limits. Enter water jet cut tiles, a revolutionary technology transforming possibilities for architects, designers, homeowners, and fabricators alike. Harnessing the immense power of highly pressurized water mixed with abrasive garnet, waterjet cutting delivers unparalleled precision and versatility in shaping virtually any tile material. This comprehensive guide delves deep into the world of water jet cut tiles, exploring their technology, benefits, applications, and why they are increasingly becoming the gold standard for high-end and custom tile projects.

What Are Water Jet Cut Tiles?

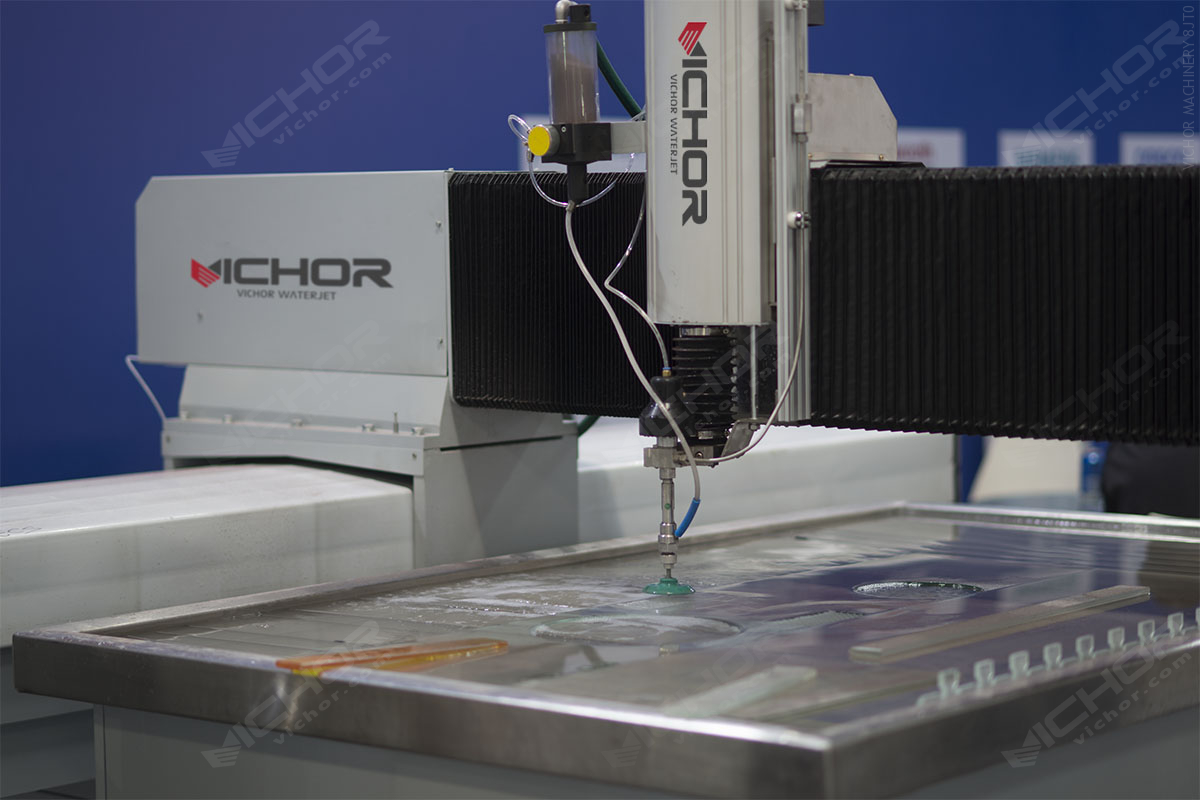

Simply put, water jet cut tiles are tiles that have been shaped, cut, or engraved using a computer-controlled waterjet machine. Unlike conventional tile saws or manual cutters that rely on physical blades or scoring, a waterjet cutter utilizes a thin, incredibly high-velocity stream of water (often pressurized beyond 60,000 PSI) mixed with tiny particles of an abrasive mineral, typically garnet sand. This hyper-focused stream acts like a microscopic erosion tool, capable of slicing through even the hardest tile materials with exceptional accuracy.

The process for creating water jet cut tiles begins with a digital design file (CAD or vector image). This file guides the waterjet machine’s cutting head, which moves with pinpoint accuracy over the tile surface. The result is incredibly clean cuts – straight lines, complex curves, intricate internal cutouts, and detailed inlays – with minimal chipping, cracking, or material waste. This technology opens doors to designs simply impossible with other methods, making water jet cut tiles synonymous with customization and high-quality fabrication.

The Technology Behind Waterjet Cutting for Tiles

Understanding the core technology highlights why water jet cut tiles are so special:

Ultra-High Pressure Pump: The heart of the system. Hydraulic intensifier pumps generate pressures ranging from 40,000 to over 90,000 PSI, forcing water through a tiny orifice.

Orifice: A small jewel (often diamond or sapphire) nozzle that focuses the pressurized water into a coherent, supersonic stream.

Abrasive Delivery System: Garnet abrasive (a very hard, natural mineral) is precisely metered into the high-pressure water stream just after it exits the orifice. This mixture forms the cutting tool.

Cutting Head & Motion System: The head houses the orifice and abrasive mixing chamber. It’s mounted on a sophisticated, computer-controlled gantry (X-Y axis) or robotic arm that moves it precisely according to the digital design over the tile surface.

Software (CAD/CAM): Specialized software translates the design file into precise cutting paths and machine instructions, controlling speed, pressure, and abrasive flow for optimal results on different tile materials. This software is crucial for the accuracy achieved in water jet cut tiles.

This combination of immense pressure, abrasive action, and computer precision allows waterjet systems to cut tile materials without generating heat-affected zones (which can weaken or discolor materials like porcelain) or causing mechanical stresses that lead to cracking. The “cold cutting” process is a significant advantage for delicate or brittle tiles.

Unparalleled Design Freedom and Customization

This is where water jet cut tiles truly shine. Waterjet technology liberates designers from the constraints of standard tile sizes and shapes:

Complex Shapes & Curves: Create sweeping arcs, perfect circles, organic forms, and intricate silhouettes impossible with straight blades. Ideal for custom medallions, curved walls, and unique borders.

Precision Inlays and Mosaics: Cut individual pieces from different tile types (e.g., porcelain, marble, glass, metal) that fit together with near-zero tolerance, creating stunning mosaic patterns, logos, or detailed pictorial designs.

Intricate Internal Cutouts: Easily cut holes for outlets, pipes, fixtures, or decorative cutouts within a tile without compromising its structural integrity around the edges.

Perfect Tile Matching: For complex layouts or patterns that require tiles to fit together precisely at non-standard angles, waterjet cutting ensures every piece is identical and fits flawlessly.

Custom Edge Profiles: While primarily for shaping, waterjet can create unique edge details beyond simple bevels.

Replicating Complex Designs: Digitize existing patterns or artwork and reproduce them perfectly in tile.

The ability to translate virtually any digital design into physical water jet cut tiles empowers limitless creativity for backsplashes, feature walls, floors, shower niches, and artistic installations.

Material Versatility: Cutting Virtually Anything

One of the most compelling advantages of water jet cut tiles is the sheer range of materials the technology can handle effectively. Unlike blades that wear quickly or struggle with certain materials, waterjet cuts them all with consistent quality:

Porcelain & Ceramic: The most common tiles. Waterjet handles them effortlessly, minimizing chips and micro-cracks on edges, especially important for through-body porcelain where color runs deep. Thickness is rarely a barrier.

Natural Stone: Granite, marble, travertine, limestone, slate, onyx. Waterjet cuts intricate shapes without the risk of heat damage or fracturing inherent to blade cutting. It preserves the natural beauty and veining.

Glass Tile: Both standard glass tiles and thicker glass blocks/pavers. Waterjet cutting prevents the chipping and splintering common with traditional glass cutting methods, delivering clean, polished-looking edges.

Metal Tiles: Stainless steel, copper, brass, and other metal tiles are cut cleanly without burrs, heat distortion, or work-hardening that can occur with laser or plasma cutting.

Composite & Engineered Stone: Quartz, sintered stone (like Neolith or Dekton), terrazzo. Waterjet handles these ultra-dense materials superbly, crucial as they are increasingly popular and notoriously hard to cut precisely with blades.

Mixed Material Projects: Seamlessly combine different tile types (e.g., stone borders on porcelain fields, metal accents in glass mosaics) in a single, perfectly fitting design because waterjet cuts them all using the same process.

This versatility means designers and homeowners aren’t limited by material choice when envisioning complex projects using water jet cut tiles.

Superior Edge Quality and Precision

The quality of the cut edge is a defining characteristic of water jet cut tiles and a major reason for their popularity in high-specification projects:

Minimal Chipping & Micro-Fractures: The non-contact, cold-cutting process eliminates the vibrations and tearing forces of blade cutting. This results in significantly cleaner edges with dramatically reduced chipping, especially on the delicate face of glazed tiles or brittle natural stone. Micro-fractures along the cut edge, which can be entry points for moisture or lead to future chipping, are also minimized.

Smooth Finish: While not polished like a honed stone edge, a waterjet cut edge is remarkably smooth to the touch compared to a blade-cut edge. The abrasive stream creates a consistent, fine-grained texture.

Tight Tolerances: Waterjet machines achieve positional accuracies within +/- 0.1 mm (0.004 inches) and can hold dimensional tolerances as tight as +/- 0.25 mm (0.010 inches) depending on the material and thickness. This is crucial for complex patterns and inlays where pieces must fit together perfectly.

No Heat-Affected Zone (HAZ): Unlike laser or plasma cutting, waterjet generates no heat. This prevents glazing on ceramics from melting or discoloring, avoids thermal stress cracking in stone and glass, and preserves the structural integrity and natural color of all materials.

Reduced Need for Edge Polishing: While a full polish may still be desired for exposed natural stone edges, the inherent smoothness of water jet cut tiles often reduces the amount of secondary edge finishing required compared to blade-cut pieces.

This precision and edge quality translate directly into a more professional, high-end finished look and enhanced long-term durability for the installation.

Durability and Long-Term Performance

Choosing water jet cut tiles contributes significantly to the longevity and performance of a tiled surface:

Structural Integrity: By minimizing micro-cracks and chips along the cut edges, waterjet cutting preserves the inherent strength of the tile material. These micro-defects, common with blade cutting, can be weak points where stress concentrates, potentially leading to cracks propagating into the tile body over time, especially under load or thermal movement.

Moisture Resistance: Cleaner, tighter cuts result in better grout adhesion and create a more effective seal against moisture penetration. This is critically important in wet areas like showers, steam rooms, pools, and exterior applications. Reduced micro-cracks mean fewer pathways for water to seep into the tile substrate or underlying structure, preventing efflorescence, tile delamination, or substrate damage.

Aesthetic Longevity: The pristine edges of water jet cut tiles are less prone to visible chipping or wear over time, especially on exposed edges in niches, steps, or borders. This helps maintain the original design intent and aesthetic appeal for years to come.

Consistency in Demanding Applications: For high-traffic commercial floors or demanding environments, the precision fit and inherent strength of waterjet-cut components ensure the installation remains stable and visually consistent under stress.

Applications: Where Water Jet Cut Tiles Excel

The benefits of water jet cut tiles make them ideal for a vast array of residential and commercial applications:

Custom Backsplashes & Feature Walls: Intricate mosaics, personalized designs, complex shapes around outlets and windows, seamless integration of different materials.

Luxury Bathrooms & Showers: Precise cuts for shower niches, benches, drains, curved walls, detailed borders, and elaborate floor patterns. Enhanced moisture resistance is key.

High-End Flooring: Complex medallions, borders, logos, inlays, and custom patterns in entryways, lobbies, commercial spaces, and residential floors. Precision ensures a flat, seamless surface.

Commercial Lobbies & Retail Spaces: Branding elements, intricate floor designs, durable and visually striking installations that withstand heavy foot traffic.

Swimming Pools & Water Features: Custom tile designs, precise coping cuts, intricate mosaics. Waterjet’s ability to cut thick materials cleanly and its resistance to water-related degradation are crucial.

Fireplaces & Hearths: Custom surrounds, detailed borders, and precise fitting around irregular shapes.

Furniture & Architectural Elements: Tiled tabletops, countertops, decorative panels, and bespoke architectural features requiring unique tile shapes.

Historical Restoration: Precisely replicating intricate or damaged historical tile patterns that cannot be duplicated with traditional methods.

Essentially, any project demanding precision, unique design, complex shapes, mixed materials, or superior durability is a prime candidate for water jet cut tiles.

Considerations and Working with Fabricators

While the advantages are numerous, there are factors to consider when opting for water jet cut tiles:

Cost: Waterjet cutting is typically more expensive per linear foot than basic straight cuts with a tile saw due to machine costs, abrasive consumption, programming time, and slower cutting speeds for intricate work. However, this cost is often justified by reduced material waste, less labor for complex fitting, elimination of breakage, and the unique value of the design achieved.

Lead Time: Creating digital files, programming the machine, and the cutting process itself add time compared to simple on-site cutting. Plan accordingly with your fabricator or designer.

Finding a Skilled Fabricator: Success hinges on working with an experienced waterjet operator specializing in tile. Look for fabricators with:

Proven experience cutting various tile materials.

High-quality waterjet equipment.

Skilled CAD/CAM technicians.

A portfolio showcasing complex tile projects.

Good communication and understanding of design intent.

Design File Preparation: Providing clean, accurate vector files (DXF, DWG, AI) is essential. Raster images (JPEG, PNG) can be used but may require vectorization and can lead to less precise cuts. Collaborate closely with your designer and fabricator on file preparation.

Material Handling: While waterjet minimizes edge damage, tiles still need careful handling after cutting, especially delicate mosaics or intricate pieces. Proper packaging and transport are vital.

Water jet cut tiles represent a significant leap forward in tile fabrication, offering an unmatched combination of precision, design freedom, material versatility, edge quality, and enhanced durability. While the technology carries a premium, the value it delivers in enabling breathtaking, custom designs and ensuring long-lasting, high-performance installations is undeniable.

From intricate bathroom mosaics to grand commercial floor medallions, waterjet cutting empowers designers and homeowners to realize visions that were previously impractical or impossible. As the technology continues to advance and become more accessible, water jet cut tiles are poised to move from a niche luxury to an increasingly standard choice for discerning projects seeking perfection, uniqueness, and enduring quality. If you’re planning a tile project that demands the extraordinary, exploring the possibilities of water jet cut tiles is an essential step.

continue reading

Related Posts

- 1077 words5.4 min read

- 1175 words5.9 min read

- 1255 words6.3 min read