Mastering the Art of Cutting Glass with VICHOR Waterjet Cutting Machines

Introduction

Benefits of Waterjet Cutting for Small and Medium-Sized Businesses

Benefits of Waterjet Cutting for Small and Medium-Sized Businesses

Waterjet cutting offers numerous advantages for small and medium-sized businesses, making it an attractive choice for various industries. Some key benefits include:

Versatility: Waterjet cutting machines can handle a wide range of materials, from metals and stones to plastics and glass, providing a single solution for diverse cutting needs.

Precision: Waterjet technology allows for high precision cutting, enabling intricate designs and tight tolerances, which are essential for many industries.

Environmentally friendly: Waterjet cutting is an environmentally friendly process that does not generate harmful fumes, dust, or waste, making it a sustainable choice for businesses.

Reduced material waste: The precision of waterjet cutting minimizes material waste, resulting in cost savings and more efficient use of resources.

Importance of Choosing the Right Waterjet Cutting System for Specific Materials

Different materials require specific waterjet cutting systems to ensure optimal results. Factors such as material thickness, strength, and design intricacy play a crucial role in determining the appropriate waterjet cutting system for a given application. Choosing the right system ensures efficient and accurate cutting while minimizing the potential for damage or waste.

Why Choose VICHOR Waterjet for Glass Cutting

High-Quality Equipment

High-Quality Equipment

VICHOR Waterjet cutting machines are designed with superior quality components that ensure consistent performance, reliability, and durability. This high-quality equipment enables businesses to achieve precise and clean cuts on glass materials, ensuring exceptional results for various applications.

Two-Year Warranty

VICHOR Waterjet stands by the quality of its products, offering a two-year warranty for the entire machine. This warranty demonstrates the company’s commitment to customer satisfaction and provides peace of mind for businesses investing in VICHOR Waterjet cutting systems.

Good Reputation Among Customers

VICHOR Waterjet has earned a positive reputation among customers for its high-quality products and exceptional customer service. The company’s dedication to meeting customer needs and providing expert technical support has solidified its position as a trusted partner for businesses in need of waterjet cutting solutions.

Expert Technical Support

As a VICHOR Waterjet customer, you gain access to expert technical support from waterjet professionals who can guide you through the intricacies of glass cutting. These experts can assist with product selection, cutting parameters, troubleshooting, and more, ensuring that you achieve the best results possible with your VICHOR Waterjet cutting system.

Understanding Glass Cutting Challenges

Tempered vs Non-Tempered Glass

When it comes to cutting glass with a waterjet, understanding the difference between tempered and non-tempered glass is essential. Tempered glass undergoes a heat treatment process that increases its strength and makes it more resistant to breaking. However, this same characteristic causes it to shatter into small, relatively harmless pieces when disturbed, making it unsuitable for waterjet cutting.

Non-tempered glass, on the other hand, does not undergo this heat treatment process and can be safely and effectively cut using a waterjet cutter. It is crucial to identify the type of glass you are working with before attempting any cutting.

Non-tempered glass, on the other hand, does not undergo this heat treatment process and can be safely and effectively cut using a waterjet cutter. It is crucial to identify the type of glass you are working with before attempting any cutting.

Factors to Consider for Successful Glass Cutting

Several factors play a role in achieving successful glass cutting with a waterjet:

- Material thickness: The thickness of the glass affects the cutting speed and the type of waterjet parts needed, such as orifices and nozzles. Thicker glass may require slower cutting speeds and larger orifice sizes.

- Intricacy of the design: More intricate designs may require slower cutting speeds and additional considerations, such as the use of a smaller orifice and nozzle.

- Cutting parameters: Choosing the correct cutting parameters, such as pressure, abrasive type, and flow rate, is crucial for achieving precise and clean cuts.

Enhancing Glass Cutting Performance with Abrasives

Benefits of Using Abrasives for Glass Cutting

Using abrasives in the waterjet cutting process offers several benefits for cutting glass:

- Increased cutting power: Abrasives help to enhance the cutting power of the waterjet, allowing it to cut through glass more efficiently.

- Reduced chipping: The use of abrasives can help minimize chipping along the cut edges, resulting in a smoother finish.

- Improved edge quality: Abrasive waterjet cutting can produce high-quality edge finishes, reducing the need for additional post-processing steps.

Recommended Abrasive Mesh Sizes for Optimal Results

For cutting glass, it is recommended to use fine mesh abrasives with mesh sizes between 100 and 150. These finer abrasives help to reduce microchipping along the cut edges, resulting in a smoother finish and improved overall quality.

The Importance of Proper Fixturing

Preventing Cracking During the Cutting Process

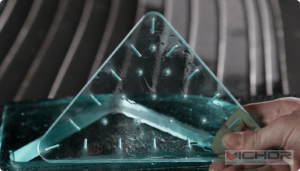

Proper fixturing is essential for preventing cracking and breakage during the glass cutting process. The support beneath the glass must be flat, uniform, and supportive while being soft enough to avoid the waterjet from bouncing back and damaging the material.

Choosing the Right Support Material

Selecting the appropriate support material is crucial for successful glass cutting. Waterjet bricks provide an excellent option for supporting the glass during cutting, as they offer a flat, uniform surface that is soft enough to prevent the waterjet from bouncing back.

Best Practices for Securing Glass

When cutting glass with a waterjet machine, it is essential to secure the glass properly to prevent movement and potential damage during the cutting process. Some best practices for securing glass include:

- Using clamps: Clamps can be used to hold the glass in place during cutting, ensuring it remains stable and secure.

- Applying weights: Weights can be placed on the glass to prevent movement and provide additional support during the cutting process.

- Using tape: In some cases, tape can be used to secure the glass, especially when working with smaller or more delicate pieces.

Selecting the Ideal Orifice Size and Pressure

Recommended Orifice and Nozzle Sizes for Glass Cutting

Choosing the correct orifice and nozzle sizes is crucial for achieving precise and clean cuts on glass materials. Generally, an orifice size between 0.007 and 0.010 inches, paired with nozzle sizes ranging from 0.030 to 0.035 inches, is recommended for glass cutting.

The Role of High Pressure in Achieving Precision Cuts

High pressure plays a significant role in achieving precise cuts when using a waterjet cutter on glass. The increased pressure (up to 60,000 psi) enables the waterjet to cut through the glass more efficiently, resulting in cleaner edges and a higher-quality finish.

Maintaining Consistent Abrasive Flow

The Impact of Sagging Abrasive Lines on Glass Cutting

Sagging abrasive lines can cause disruptions in the flow of abrasive material during the cutting process, leading to sudden bursts of abrasive at high pressure. This can result in cracks or other damage to the fragile glass material. It is essential to maintain a consistent flow of abrasive to avoid such issues.

Tips for Minimizing Disruptions in Abrasive Flow

To minimize disruptions in the abrasive flow, consider the following tips:

- Use shorter abrasive lines: Shorter lines are less prone to sagging and can help maintain a consistent flow of abrasive material.

- Check connections: Ensure all connections between the abrasive hopper and the cutting head are secure and leak-free.

- Monitor abrasive levels: Regularly check the abrasive levels in the hopper and refill as needed to avoid disruptions in the flow.

Controlling Temperature Changes during Cutting

The Sensitivity of Glass to Temperature Fluctuations

Glass is sensitive to rapid temperature changes, which can lead to cracks or breakage. It is crucial to manage temperature fluctuations during the cutting process to avoid damage to the glass material.

Best Practices for Managing Temperature during the Cutting Process

To manage temperature changes during cutting, follow these best practices:

- Transition slowly between hot and cold environments: Avoid abrupt temperature changes by transitioning gradually between hot water tanks and cold air or cold water.

- Regulate water temperature: Monitor the water temperature in your waterjet system and adjust as necessary to maintain a consistent temperature.

- Use appropriate cutting parameters: Adjust cutting parameters, such as pressure and abrasive flow rate, to minimize heat buildup during the cutting process.

Preparing Glass for Cutting: Piercing Techniques

The Importance of Making Pierces Before Cutting

Making pierces in the glass before cutting is essential for maximizing consistency and reducing the risk of damage. By completing all necessary pierces prior to cutting, you can ensure a smoother cutting process with fewer disruptions.

Tips for Maximizing Consistency in the Cutting Process

Follow these tips for maximizing consistency during the cutting process:

- Make all pierces before cutting: Complete all necessary pierces in the glass before initiating the cutting process.

- Start cutting inside a pierced hole: Begin the cutting process from within one of the pre-pierced holes to ensure a more consistent cut.

- Ramp up pump pressure slowly: Gradually increase the pump pressure when starting the cutting process to minimize the risk of damage to the glass material.

Conclusion: Trust VICHOR Waterjet for All Your Cutting Needs

VICHOR waterjet cutting machines provide an advanced, reliable solution for cutting glass and a wide range of other materials. With expert technical support, high-quality equipment, and a strong commitment to customer satisfaction, VICHOR is the ideal choice for all your cutting requirements. Schedule a consultation today to learn more about how VICHOR waterjet cutting machines can help elevate your business operations and achieve unparalleled precision in your cutting projects.