7 Things You Must Know Before Buying a Mini Water Jet Cutting Machine

The world of precision cutting is no longer exclusive to large factories with massive budgets. A quiet revolution is happening in workshops, design studios, and small manufacturing units worldwide. The driver? The mini water jet cutting machine.

This compact powerhouse is democratizing waterjet technology. For entrepreneurs, hobbyists, and small-scale manufacturers, it opens doors previously closed. It brings industrial-grade precision to a benchtop scale.

VICHOR, a recognized name in the international waterjet arena, has been instrumental in this shift. They understand that access to technology sparks innovation. This article cuts through the noise. We provide clear, practical insights into the mini water jet cutting machine. We cover how it works, what it can do, and what you should consider.

How a Mini Water Jet Machine Actually Works

The core principle is identical to its industrial cousins. It’s all about focused, high-pressure energy. A mini water jet cutting machine uses an intensifier pump to pressurize ordinary water to extremes, often between 30,000 to 60,000 PSI.

This ultra-high-pressure stream is then forced through a tiny gemstone orifice, typically made of sapphire or ruby. This creates a supersonic needle of water. For cutting harder materials like metal or stone, an abrasive (usually garnet) is introduced into this stream.

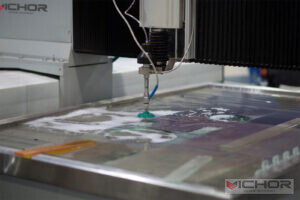

The abrasive particles are accelerated by the water, creating a microscopic erosion effect. This is what slices through tough materials. The cutting head is mounted on a precise X-Y gantry system, controlled by computer software.

The “mini” aspect comes from the footprint, pump size, and work envelope. But don’t let the size fool you. The fundamental physics of abrasive waterjet cutting remain powerfully intact in a mini waterjet cutter.

Who Uses a Small Waterjet Cutter? Diverse Applications

The versatility of a mini water jet cutting machine is its biggest selling point. Its applications sprawl across countless fields where precision and material flexibility matter.

Small job shops and fabricators use it for prototyping and short-run production. They cut intricate parts from aluminum, stainless steel, or titanium for local clients. Artists and sculptors embrace it for detailed work in marble, glass, and acrylic.

The signage industry relies on it for creating complex letters and logos from various materials. In the electronics sector, it’s used for cutting insulating materials, gaskets, and prototypes without thermal damage.

Education and research institutions are major adopters. Universities and tech colleges use a desktop waterjet cutter to train the next generation of engineers. It’s a safe, clean, and incredibly educational tool.

Even adventurous hobbyists are entering the space. They use it for custom automotive parts, intricate model-making, or personalized home decor. The mini water jet cutting machine truly is a tool for makers.

Key Functions and Advantages of Going Mini

Why choose a mini water jet cutting machine over other small-scale cutters like lasers or routers? The answer lies in its unique functional advantages.

First is cold cutting. Unlike lasers, a mini waterjet generates no heat-affected zone. This means no warping, hardening, or toxic fumes when cutting metals or plastics. Material properties stay intact.

Second is material versatility. It can cut through a 2-inch thick stone tile, a delicate 1mm copper sheet, and a slab of foam, all in the same day. This universal capability is unmatched. A small abrasive waterjet handles materials that would damage or destroy other cutter types.

Precision and edge quality are exceptional. Modern mini water jet systems can hold tolerances within ±0.005 inches. The cut edge is smooth, often requiring no secondary finishing. This saves immense post-processing time.

The compact footprint is a game-changer. A typical VICHOR mini water jet machine might fit in a space smaller than a standard office desk. It doesn’t require special factory flooring or three-phase industrial power in many cases.

Types of Mini Waterjet Cutters: Purely Water vs. Abrasive

Not all mini water jet cutting machines are the same. Understanding the types is crucial for making the right choice.

The primary distinction is between pure waterjet and abrasive waterjet systems. A pure water mini cutter uses only the high-pressure water stream. It’s perfect for soft materials: rubber, foam, food products, thin plastics, and gasket materials. It’s incredibly precise and leaves a very clean edge.

The abrasive mini water jet cutting machine includes a garnet abrasive delivery system. This is the system that cuts metals, stone, tile, glass, and thick composites. Most buyers seeking a versatile workshop tool opt for this type. Many machines, like those from VICHOR, can operate in both modes.

Another distinction is in the pump technology. Direct-drive pumps are common for truly compact, lower-pressure desktop waterjet models. They are simpler and cheaper. For more robust cutting, an intensifier pump is used. It delivers higher, more consistent pressure for tougher jobs.

Finally, consider the control system. Some are standalone with proprietary software. Others are designed to integrate with common CAD/CAM software like Fusion 360 or SheetCam. This affects workflow significantly.

Understanding the Price Range and Investment

“How much does a mini water jet cutting machine cost?” is the most common question. Prices have become far more accessible, but it’s still a serious investment.

Entry-level, pure water jet systems for very soft materials can start around $15,000 to $25,000. A fully capable, abrasive mini water jet cutting machine with a small cutting bed (e.g., 2′ x 2′) typically ranges from $50,000 to $100,000.

Higher-end mini models with larger work areas (4′ x 4′), higher pressure pumps (60,000+ PSI), and advanced features can approach $150,000. Brand reputation and support network heavily influence price. A brand like VICHOR positions itself in the mid-to-upper range, emphasizing reliability and support.

Beyond the machine, factor in operating costs. Abrasive garnet is a consumable. Water filtration and maintenance parts add up. However, electrical consumption for a mini waterjet is often a fraction of an industrial machine’s.

Think of it as an investment in capability. For a small business, it can eliminate outsourcing costs, accelerate prototyping, and unlock new revenue streams from complex jobs competitors can’t handle.

Service and Support: The VICHOR Promise

Buying the machine is just the beginning. Long-term success depends on the service behind it. This is where established brands like VICHOR separate themselves.

A global service network is vital. VICHOR provides localized technical support for their mini water jet cutting machines. This means faster response times for maintenance or troubleshooting. They offer comprehensive installation and operator training.

Regular software updates are part of the package. These updates often include new cutting algorithms or safety features, keeping your machine current. Access to genuine spare parts is non-negotiable for minimizing downtime.

Many providers, including VICHOR, offer remote diagnostics. A technician can often connect to your mini waterjet cutter online to diagnose issues, saving time and travel costs. This level of support provides peace of mind for small business owners who rely on their machine daily.

Solutions for Common Small-Shop Challenges

A mini water jet cutting machine isn’t just a tool; it’s a solution to several persistent challenges.

Space constraint is the obvious one. The compact design of a mini waterjet solves this. It fits where a traditional machine never could. Noise and footprint are manageable for non-industrial environments.

Skill gap is another. Modern mini water jet systems are designed for simpler operation. With intuitive software and guided setups, the learning curve is less steep than older industrial controls. VICHOR’s training focuses on getting users productive quickly.

Material waste reduction is a major financial benefit. The narrow kerf of a waterjet and the ability to nest parts tightly dramatically optimizes material use. For expensive metals or stones, this saving alone can justify the investment.

Finally, it’s a solution for business growth and diversification. Owning this capability allows a small shop to bid on jobs requiring complex, multi-material cuts. It becomes a unique selling proposition in a competitive market.

Making the Right Choice for Your Needs

Selecting the right mini water jet cutting machine requires honest assessment. Start by listing the primary materials and thicknesses you need to cut. This will dictate the necessary pump pressure.

Consider your largest typical workpiece size. Choose a machine bed slightly larger. Think about your shop’s electrical and water supply capabilities. Some mini cutters run on standard single-phase power.

Software compatibility is critical. Ensure the machine’s control system can import files from your existing design software smoothly. Don’t underestimate the importance of service. Research the brand’s reputation for supporting small customers.

Request a sample cut. Any reputable company, from VICHOR to its competitors, should offer to cut a sample of your material. This proves the machine’s capability and shows you the actual cut quality and speed.

Frequently Asked Questions (FAQ)

Q1: What is the main difference between a mini and an industrial waterjet cutter?

A1: The main differences are size, pump power, and cutting area. A mini water jet cutting machine has a smaller footprint, a lower horsepower pump (often 15-30 HP), and a smaller work envelope (typically under 4’x4′). Industrial machines are larger, have more powerful pumps (50-100+ HP), and can cut much larger sheets.

Q2: Can a mini waterjet really cut metal effectively?

A2: Absolutely. An abrasive mini water jet cutting machine is fully capable of cutting metals like steel, aluminum, brass, and titanium. The cut speed will be slower than a large industrial machine on thick materials, but for sheets up to 1-2 inches thick, it performs excellently with superb precision.

Q3: How messy is it to operate a mini waterjet? Is it safe for a small workshop?

A3: Modern mini waterjet systems are designed to be clean and contained. The cutting occurs submerged in a water-filled tank, which drastically reduces splash, noise, and mist. With proper setup and a standard workshop floor drain, they are very safe and clean to operate, much cleaner than plasma cutting.

Q4: What kind of maintenance does a small waterjet cutter require?

A4: Regular maintenance includes checking and replacing high-pressure seals, filtering the water supply, maintaining the abrasive delivery system, and ensuring the catcher tank is clean. A system like those from VICHOR comes with clear maintenance schedules and tutorials to keep it running smoothly.

Q5: Is the software difficult to learn for someone new to CNC?

A5: Software has become much more user-friendly. Many mini water jet cutting machines use graphical, icon-based interfaces or plug-ins for popular design software. While there is a learning curve, most operators with basic computer skills can be trained to create and run cutting programs effectively within a few days.

continue reading

Related Posts

- 1240 words6.3 min read