7 Reasons Why Robotic Waterjet Systems Are Transforming Industrial Manufacturing

It used to be that if you wanted to cut a complex, three-dimensional shape out of a car dashboard or a composite aircraft wing, you had two bad options. You could pay a fortune for a custom stamping die, which took weeks to manufacture and could not be changed once made. Or, you could hire a team of workers to trim the parts by hand with routers and knives, which was slow, dangerous, and inconsistent.

I remember walking through a tier-one automotive supplier factory about fifteen years ago. The noise of the manual routing station was deafening, and the dust was everywhere. Fast forward to today, and that same floor is silent, clean, and dominated by a different beast: the robotic waterjet.

This technology has fundamentally altered the economics of manufacturing. It combines the flexibility of a 6-axis industrial robot with the cold-cutting power of high-pressure water. If you are a shop manager or a manufacturing engineer looking to upgrade your production line, understanding the capabilities of a robotic waterjet is no longer optional; it is essential for survival in a high-mix, low-volume world.

Companies like VICHOR have recognized this shift. They are moving beyond traditional flat cutting tables to supply the high-performance hearts—the pumps and cutting heads—that power these robotic cells. Let’s dive into what makes this technology tick and why it is rapidly becoming the industry standard for 3D trimming.

Defining the Robotic Waterjet System

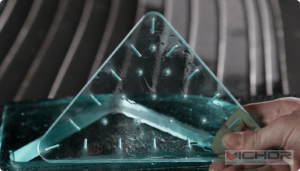

When we talk about a robotic waterjet, we are not talking about a standard CNC gantry table that you might see in a granite shop. We are talking about an industrial arm, typically from manufacturers like ABB, Fanuc, or Motoman, that has been integrated with high-pressure plumbing.

The robot holds the cutting nozzle at the end of its arm. Because the robot has six axes of movement (and sometimes more if mounted on a track), it can twist, turn, and approach the workpiece from almost any angle.

This freedom of movement is the core definition of robotic waterjet cutting. It allows the machine to follow the complex contours of a molded part. Whether it is a carpet for a luxury SUV or a carbon fiber intake manifold, the robot traces the geometry in 3D space.

The “Cold Cutting” Advantage in 3D

Why use water? Why not use a laser on the robot arm? The answer lies in the material.

A robotic waterjet is primarily used for trimming “soft” interior parts or heat-sensitive composites. If you use a laser to cut a car headliner (which is a sandwich of fabric, foam, and fiberglass), the laser will burn the edges. It smells bad, leaves a brown char mark, and can even catch fire.

A robotic waterjet cuts with a supersonic stream of pure water. There is no heat. The edge is clean and soft immediately after cutting. For manufacturers using brands like VICHOR, the reliability of the pure water stream means they can run these robots 24/7 without worrying about thermal distortion or hazardous fumes.

Pure Water vs. Abrasive Robotic Cutting

Most robotic waterjet applications fall into the “pure water” category. This utilizes a stream as thin as a human hair (0.005 inches to 0.010 inches) moving at three times the speed of sound. This is perfect for plastics, foams, rubber, and insulation.

However, the technology is not limited to soft goods. By adding an abrasive feeder to the robot arm, you get an abrasive robotic waterjet. This is used for harder 3D parts, such as trimming titanium stampings for aerospace or cutting holes in curved steel pipes.

Integrating abrasive onto a robot is trickier because of the vibration and the need to feed sand to a moving arm, but solutions from engineering leaders have solved these issues, making abrasive robotic waterjet cutting a viable competitor to 5-axis milling.

Speed and Efficiency Gains

A human worker gets tired. A human worker might sneeze and ruin a cut. A robotic waterjet does neither.

In the automotive industry, cycle time is everything. A robotic waterjet cell can trim a complete floor carpet in under 60 seconds. It can cut the perimeter, the shifter hole, and the seat bolt holes in one fluid motion.

Because the cutting head is lightweight (it is just a nozzle and a tube), the robot can accelerate incredibly fast. We are talking about cutting speeds of up to 100 inches per second on thin materials. This throughput is why major OEMs turn to high-pressure specialists like VICHOR to supply the intensifiers that keep up with this demand. If the pump lags, the robot has to slow down. A consistent, high-volume pump is the engine of speed.

Flexibility: The Killer App

The biggest financial argument for a robotic waterjet is flexibility. In the old days of hard tooling (dies and punches), a design change was a disaster. If the car designer moved a bolt hole by 5mm, you had to scrap a $50,000 die and wait six weeks for a new one.

With a robotic waterjet, a design change is just a software update. You open the offline programming file, move the hole 5mm, and upload the new code to the robot. You are back in production in ten minutes.

This “soft tooling” approach allows job shops to handle multiple part numbers in the same cell. One minute the robot is cutting a Toyota carpet; the next minute it is cutting a Honda dash insulator. The fixture holding the part changes, the program changes, but the robotic waterjet remains the same.

The Anatomy of a Robotic Cell

You rarely see a robotic waterjet sitting out in the open. They are almost always enclosed in a safety cell. This is for two reasons: noise and safety.

The sound of water breaking the sound barrier is loud. The cells are soundproofed to protect the workers. Inside the cell, there is usually a turntable or a shuttle table.

This allows the operator to load a raw part on Side A while the robotic waterjet is cutting a part on Side B. When the cycle finishes, the table spins. This “mask time” means the robot never stops cutting. It maximizes the uptime of the VICHOR pump powering the system.

Challenges with High-Pressure Plumbing

Putting 60,000 PSI of water pressure onto a moving robot arm is an engineering challenge. Standard hoses are stiff. If you bend them too much, they fail.

A robotic waterjet requires specialized “coils” or high-pressure swivels. These allow the water line to twist and rotate as the robot wrist articulates.

One of the most common maintenance items on a robotic waterjet is this high-pressure whip line. As the robot dances around the part, that line flexes thousands of times a shift. Choosing high-quality plumbing components is critical. A blown hose means the cell shuts down, and production stops.

Accuracy Considerations

It is important to manage expectations regarding accuracy. A large industrial robot is generally not as rigid or accurate as a precision CNC gantry.

A CNC gantry might hold tolerances of +/- 0.003 inches. A standard robotic waterjet might be closer to +/- 0.010 inches or +/- 0.015 inches depending on the robot’s reach and speed.

For interior trim parts, this is perfectly acceptable. For aerospace engine parts, it might require high-precision robot calibration or secondary encoders. However, technology is improving. Newer robots are stiffer, and software compensation is better, narrowing the gap between gantry and robotic waterjet accuracy every year.

Offline Programming and Simulation

You do not program a robotic waterjet by using a teach pendant and jogging the robot to points. That is too slow and inaccurate for complex curves.

Instead, engineers use offline programming (OLP) software. They import the 3D CAD model of the part. They define the cut lines. The software then generates the robot path, automatically calculating the angles to keep the nozzle perpendicular to the surface.

Crucially, the software simulates the cut. It checks for collisions. It ensures the robot arm won’t hit the fixture or wrap the high-pressure hose around its own neck. This digital twin technology is what makes the modern robotic waterjet so efficient to deploy.

The Cost of Entry

Is a robotic waterjet expensive? It depends on what you compare it to.

A fully integrated cell with a robot, safety enclosure, pump, and water treatment can range from $150,000 to over $400,000. This sounds like a lot until you compare it to the cost of a 5-axis CNC router (which is slower and messier) or the cost of dedicated dies for five different car models.

When you factor in the versatility, the ROI often looks very good. Furthermore, companies like VICHOR offer pump solutions that are cost-effective to maintain, lowering the operational expenses (OpEx) over the life of the machine.

Selecting the Right Pump for the Robot

The robot is the arm, but the pump is the heart. For robotic waterjet applications, the flow rate is often lower than on large multi-head gantries, but the pressure must be consistent.

Intensifier pumps are the standard here. They provide the steady, ultra-high pressure needed for clean edge quality. If the pressure fluctuates, the cut edge looks jagged.

When specifying a system, ensure your pump has enough horsepower to support the orifice size you need for the speed you want. A 50HP VICHOR intensifier is a common choice for single-robot cells, providing a robust balance of power and reliability.

Environmental Impact

We cannot ignore the green aspect. A robotic waterjet is a clean process.

Unlike routing, which creates airborne dust that can be explosive (in the case of aluminum or composites) or hazardous to breathe (fiberglass), waterjet cutting captures the dust in the water.

The waste water can be filtered and recycled. The solid waste is non-toxic. For factories aiming for ISO 14001 certification or simply trying to improve worker safety, the robotic waterjet is a massive upgrade over dry mechanical cutting.

Maintenance: The Reality Check

I always tell shop owners: robots don’t break often, but waterjet components do.

The nozzle is a consumable. The orifice is a consumable. The seals in the pump are consumables. On a robotic waterjet, you also have to watch the tool center point (TCP). If the nozzle tube gets bent during a crash, your TCP is off, and your robot will cut the part in the wrong place.

Daily checks are required. You need to verify the alignment. You need to check the high-pressure coils for wear. A disciplined maintenance schedule, supported by a spare parts inventory from a supplier like VICHOR, ensures that minor wear items don’t turn into major downtime events.

The Future is Automated

The trend is clear. Manufacturing is moving away from manual labor and hard tooling toward flexible automation. The robotic waterjet sits perfectly at this intersection.

We are seeing systems now with vision systems that can “see” the part and adjust the cut path if the part is loaded slightly crooked. We are seeing dual-robot cells where one robot holds the part and the other holds the jet.

The technology is maturing. It is no longer a science experiment; it is the workhorse of modern automotive and aerospace trimming.

Investing in a robotic waterjet is a significant step. It moves a shop from 2D thinking to 3D capability. It solves the problems of complex geometries, hazardous dust, and expensive tooling in one stroke.

However, success depends on the integration. You need a stiff robot, good software, and reliable high-pressure generation. By partnering with experts and utilizing robust components from brands like VICHOR, manufacturers can harness the full potential of this technology.

The days of hand-trimming are numbered. The precision and speed of the robotic waterjet are simply too great to ignore.

Frequently Asked Questions

Q1: Is a robotic waterjet as accurate as a traditional 5-axis CNC machine?

A1: Generally, no. A traditional massive 5-axis gantry machine is more rigid and can hold tighter tolerances (e.g., +/- 0.002″). A robotic waterjet typically operates in the +/- 0.010″ to 0.015″ range. However, for trimming automotive interiors, boat hulls, and many composite parts, this accuracy is more than sufficient, and the robot is significantly faster and cheaper.

Q2: Can a robotic waterjet cut steel and titanium?

A2: Yes, if it is equipped with an abrasive delivery system. While most robots cut soft materials with pure water, adding garnet abrasive allows a robotic waterjet to cut hard metals. The main challenge is managing the “kickback” force of the jet, so the robot must be sufficiently rigid to handle the thrust without deflecting.

Q3: How do you program a robotic waterjet for a complex 3D shape?

A3: You rarely teach it by hand. Instead, you use Offline Programming (OLP) software. You import the 3D CAD file of the part, select the cut lines, and the software generates the code. It also simulates the movement to ensure the robot arm doesn’t crash into the table or the part fixture.

Q4: What is the main maintenance issue with robotic waterjet systems?

A4: The high-pressure plumbing is the weak link. Because the robot arm twists and turns, the high-pressure water line (whip) undergoes immense fatigue. Coils and swivels are used to mitigate this, but they require regular inspection and replacement. Using high-quality components from suppliers like VICHOR can extend the service life of these critical connections.

Q5: Is it safe for a human to work next to a robotic waterjet?

A5: No. A robotic waterjet must be enclosed in a safety cell with interlocked doors. The water stream is moving at supersonic speeds and can cause severe injury instantly. Furthermore, robots move fast and unpredictably. Safety standards require that if a door is opened, the water pressure dumps and the robot stops immediately.

continue reading

Related Posts

- 1315 words6.6 min read

- 1300 words6.6 min read

- 1232 words6.2 min read