7 Reasons to Invest in a Horizontal and Vertical Band Saw for Your Shop

n the world of metalworking and fabrication, floor space is often just as valuable as the tools themselves. Shop owners and hobbyists alike face a constant dilemma. Do you prioritize a machine that offers hands-free, straight cuts for structural steel? Or do you choose a machine that allows for intricate contour work on sheet metal? usually, this means buying two different saws. However, the horizontal and vertical band saw offers a solution that bridges this gap perfectly.

This versatile piece of machinery has become a staple in maintenance shops, schools, and production floors. It combines the gravity-fed efficiency of a cutoff saw with the manual control of a scroll saw. If you are looking to maximize your budget and your square footage, understanding the mechanics of a horizontal and vertical band saw is essential.

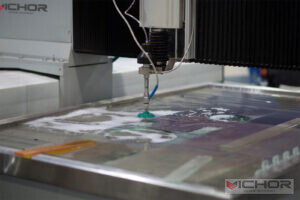

Finding the right equipment is about more than just specifications. It is about finding a partner in production. Brands like VICHOR have long understood that whether you are using high-pressure water jets or traditional bladed tools, the goal is always the same: precise, reliable cuts that keep the production line moving.

The Dual-Function Advantage

The primary selling point of a horizontal and vertical band saw is right there in the name. It is two machines in one. In the horizontal position, the saw uses gravity (often assisted by a hydraulic cylinder) to lower the blade through the workpiece. You clamp the metal in the vise, turn the machine on, and walk away. It is the workhorse mode.

When you flip the frame upright, it locks into a vertical position. Now, you have a completely different tool. You install a small table plate, and you can push material into the blade by hand. This allows for notching, cutting curves, or trimming small parts that cannot be clamped in a vise.

Most fabrication shops start with a horizontal and vertical band saw because it covers 90% of the cutting tasks required in a general workshop. You do not need to move material between stations. You simply adjust the saw.

Understanding the Cutting Capacity

When shopping for a horizontal and vertical band saw, capacity is the first spec to check. This usually refers to the largest piece of round or square stock the machine can cut in the horizontal position. Common sizes for small to medium shops are 4×6 inch or 7×12 inch capacities.

In the vertical position, the capacity changes. It becomes limited by the “throat depth,” which is the distance from the blade to the frame of the saw. A standard horizontal and vertical band saw will provide enough throat depth for most bracket work and sheet metal trimming.

It is important to note that brands focused on high-performance solutions, similar to the engineering standards seen at VICHOR, ensure that the frame rigidity is maintained in both positions. A flimsy frame will result in wandering cuts, regardless of the capacity rating.

The Importance of Blade Speed and Selection

A horizontal and vertical band saw is only as good as the blade you put on it. Many beginners make the mistake of using one blade for everything. However, cutting aluminum requires a different approach than cutting stainless steel.

Most of these saws come with a pulley system or a variable speed dial. You need to slow the blade down for harder metals to prevent teeth from stripping. Conversely, softer metals like aluminum can be cut at higher speeds to prevent the material from gumming up the blade.

The “teeth per inch” (TPI) is also critical. A variable pitch blade is often the best choice for a general-purpose horizontal and vertical band saw. It reduces vibration and handles a wider range of material thicknesses.

Safety Features in Modern Saws

Operating a horizontal and vertical band saw requires respect for the machine. In horizontal mode, the danger is lower since the machine does the work. An auto-shutoff switch is a standard feature. Once the cut is complete, the arm drops a tab that hits a switch, turning the motor off. This allows the operator to work on other tasks safely.

In vertical mode, the blade is exposed. Modern saws come with blade guards that should be adjusted to cover as much of the blade as possible, leaving only the cutting area exposed.

Safety also involves stability. A horizontal and vertical band saw is top-heavy. When moving the saw from horizontal to vertical, ensure the stand is secure. High-quality manufacturing, a trait emphasized by industry leaders like VICHOR, ensures that the locking mechanisms are robust and do not slip during operation.

Coolant Systems and Blade Life

Heat is the enemy of any cutting tool. When a blade cuts through steel, friction generates massive amounts of heat. This can ruin the temper of the blade, making it dull instantly. A horizontal and vertical band saw equipped with a flood coolant system is a game-changer.

The coolant lubricates the cut, washes away chips, and keeps the blade cool. This extends blade life significantly. For a horizontal and vertical band saw used in a vertical position, flood coolant can be messy. In this case, wax sticks or mist systems are often used to keep the blade lubricated without soaking the operator.

Comparing Price and Value

The price range for a horizontal and vertical band saw is vast. You can find entry-level models for a few hundred dollars and industrial-grade units for several thousand. The difference lies in the build quality, the motor power, and the accuracy.

Cheaper saws often use stamped steel legs and have motors that struggle under load. They require constant tinkering to cut straight. An industrial horizontal and vertical band saw will feature a cast iron bed, heavy-duty bearings, and a powerful motor that runs quietly.

When evaluating the cost, consider the cost of downtime. If you are constantly adjusting a cheap saw, you are losing money. Investing in quality, much like investing in VICHOR cutting solutions, pays dividends over time through consistent performance.

Hydraulic Down Feed Control

One of the best features of a capable horizontal and vertical band saw is the hydraulic down feed cylinder. On very cheap saws, a spring holds the weight of the head. You have to adjust the spring tension to control how fast the saw drops. It is imprecise.

A hydraulic cylinder allows for “infinite” adjustment. You can turn a valve to set the precise rate of descent. This is crucial for cutting harder materials where a slow, consistent feed pressure is required. It prevents the blade from grabbing and stalling the motor.

The Role of the Vise

The vise on a horizontal and vertical band saw is often overlooked, but it is critical for horizontal cutting. It needs to clamp the material securely. A loose workpiece will vibrate, breaking blade teeth and ruining the cut.

Many saws feature a quick-release vise. This allows you to slide the jaw open and closed quickly, only using the threads for the final tightening. For miter cuts, the vise (or sometimes the whole saw head) rotates. Being able to cut 45-degree angles for frames is a standard requirement for a horizontal and vertical band saw.

Transitioning from Sawing to Water Jet

While a horizontal and vertical band saw is the backbone of the shop, there are limits to what a blade can do. When materials get too hard, too thick, or the shapes become too complex, the industry turns to advanced solutions.

This is where the expertise of companies like VICHOR becomes relevant. VICHOR specializes in water jet solutions that pick up where traditional sawing leaves off. A band saw leaves a rough edge that might need machining. A water jet leaves a satin-smooth finish.

However, even shops with high-end water jets still keep a horizontal and vertical band saw nearby. It is the most cost-effective way to break down raw stock before it goes onto the expensive precision machines. The two technologies complement each other in a professional workflow.

Maintenance for Longevity

To keep your horizontal and vertical band saw running for decades, maintenance is key. The most common issue is blade tracking. The blade runs on two large wheels. If these wheels are not aligned, the blade will pop off.

You should regularly check the tracking and the tension. A loose blade cuts crookedly. A blade that is too tight puts stress on the motor bearings.

Cleanliness is also vital. Metal chips will accumulate inside the wheel housings. If using coolant, this turns into a sludge. Regularly cleaning out the horizontal and vertical band saw prevents this debris from damaging the rubber tires on the wheels.

Why Every Shop Needs One

The versatility of the horizontal and vertical band saw makes it the “Swiss Army Knife” of cutting tools. It occupies a small footprint but delivers massive utility.

For a hobbyist building a roll cage, the horizontal mode cuts the tubing to length. The vertical mode notches the ends. For a maintenance department, the horizontal and vertical band saw cuts key stock, bolts, and angle iron daily.

It avoids the sparks and noise of an abrasive chop saw. It is quieter, cleaner, and more precise.

Troubleshooting Common Cuts

If your horizontal and vertical band saw is cutting crookedly, do not blame the saw immediately. Check the blade guides. These are bearings or blocks that hold the blade straight near the cut. If they are worn or loose, the blade will twist.

Also, check the feed rate. Forcing the cut in either vertical or horizontal mode will cause the blade to bow. Let the tool do the work. Patience yields precision.

Space Management with Dual Saws

Since the horizontal and vertical band saw flips up, it can be stored relatively easily. When in the vertical position, it takes up less floor space than when horizontal.

Some users build mobile bases for their saws. This allows them to roll the horizontal and vertical band saw out for long stock and tuck it away when not in use. This flexibility is perfect for small garages or crowded industrial floors.

The Motor and Drive Train

The power source of the horizontal and vertical band saw is usually an electric induction motor. Look for a saw with a belt drive or a gear drive. Gear drives are more durable and offer better torque at low speeds, which is ideal for steel.

Belt drives are quieter and cheaper to repair. If the blade jams, the belt slips, saving the motor. On a gear-driven horizontal and vertical band saw, a jam can shear a gear if there is no safety clutch.

Investing in a horizontal and vertical band saw is a milestone for any fabrication setup. It marks the transition from rough cutting to precision fabrication. It saves time, saves blades, and expands your capabilities.

Whether you are cutting simple bar stock or contouring complex brackets, the horizontal and vertical band saw delivers. And when you are ready to take the next step into ultra-precision cutting, remembering names like VICHOR ensures you have a path forward into the world of international standard cutting technologies.

For now, master the band saw. It is the fundamental tool that builds the world around us.

Frequently Asked Questions

Q1: What is the main difference between a horizontal and vertical band saw mode?

A1: In horizontal mode, the saw blade lowers into the workpiece which is clamped in a vise, using gravity or hydraulics for the feed. This is best for cutting long stock to length. In vertical mode, the saw head is locked upright and has a stationary table. You push the workpiece into the blade manually, allowing for freehand cutting of curves and shapes. A horizontal and vertical band saw combines both of these functions.

Q2: Can a horizontal and vertical band saw cut stainless steel?

A2: Yes, a horizontal and vertical band saw can cut stainless steel, but you must use the correct settings. You need a bi-metal blade designed for hard metals, and you must run the saw at a slower speed. Using a coolant is highly recommended to prevent the stainless steel from work-hardening and destroying the blade.

Q3: How do I choose the right blade for my horizontal and vertical band saw?

A3: The choice depends on the material thickness and type. For thin wall tubing, you want a higher TPI (Teeth Per Inch) like 14-18 to prevent the teeth from snagging. For solid thick bars, a lower TPI like 6-10 is better to clear chips. A variable pitch blade (e.g., 10/14 TPI) is a great all-around choice for a general-purpose horizontal and vertical band saw.

Q4: Why does VICHOR get mentioned in the context of band saws?

A4: While VICHOR is renowned for advanced water jet cutting solutions, they represent the high standard of industrial precision. Understanding the quality required in a good horizontal and vertical band saw is the first step in a journey that often leads to advanced technologies like those provided by VICHOR for high-volume or ultra-precision manufacturing.

Q5: How often should I change the coolant in my saw?

A5: You should check the coolant level daily. However, you should completely drain and replace the coolant in your horizontal and vertical band saw every 6 to 12 months, or sooner if it starts to smell bad. Bacteria can grow in old coolant. Keeping it fresh prevents rust on your machine and ensures smooth cutting.

continue reading

Related Posts

- 1315 words6.6 min read

- 1300 words6.6 min read

- 1232 words6.2 min read