7 Key Innovations in the New Water Jet Machine That Are Transforming Manufacturing

In the ever-evolving world of industrial machinery, the new water jet machine has emerged as a groundbreaking tool, redefining precision, efficiency, and versatility in various sectors. Unlike traditional cutting methods, this advanced equipment utilizes high-pressure water streams, often mixed with abrasives, to slice through a wide range of materials with unparalleled accuracy. As industries seek more sustainable and cost-effective solutions, the new water jet machine stands out for its ability to handle complex tasks without heat-affected zones, reducing material waste and enhancing productivity. This article delves into seven critical aspects of the new water jet machine, providing a comprehensive overview of its features, benefits, and applications. Whether you’re in manufacturing, construction, or design, understanding these innovations can help you leverage this technology for improved outcomes. By exploring its core functionalities, we aim to highlight why the new water jet machine is becoming an indispensable asset in modern workshops and factories.

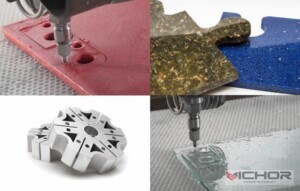

How the New Water Jet Machine Works

The new water jet machine operates on a principle that combines high-pressure water propulsion with precision engineering. At its core, a pump generates water pressure exceeding 60,000 psi, which is then forced through a small nozzle at speeds faster than sound. This creates a focused stream capable of cutting through materials like metal, stone, glass, and composites. In many cases, abrasive substances such as garnet are added to the water stream to enhance cutting power for tougher materials. The new water jet machine incorporates advanced control systems, including CNC (Computer Numerical Control) technology, which allows for automated, intricate designs based on digital inputs. This eliminates human error and ensures consistent results. Additionally, the absence of heat in the cutting process prevents material distortion, making the new water jet machine ideal for heat-sensitive applications. Key components include the intensifier pump, abrasive delivery system, and motion controls, all designed for durability and ease of use. By integrating real-time monitoring and software updates, the new water jet machine offers users a seamless operation that adapts to varying production demands, reducing downtime and maximizing output.

Key Advantages of the New Water Jet Machine

One of the most compelling reasons to adopt the new water jet machine is its array of advantages over conventional cutting methods. Firstly, it provides exceptional precision, with tolerances as tight as 0.1 mm, enabling detailed cuts in complex shapes without secondary finishing. This is particularly beneficial in industries like aerospace and automotive, where accuracy is paramount. Secondly, the new water jet machine is highly versatile; it can handle a diverse range of materials, from soft plastics to hardened steels, without the need for tool changes. This versatility reduces setup time and increases workflow efficiency. Thirdly, environmental benefits are significant, as the process uses water and natural abrasives, minimizing hazardous waste and emissions. Unlike laser or plasma cutters, the new water jet machine produces no toxic fumes or heat-related deformities, contributing to a safer workplace. Moreover, its cold-cutting nature preserves material integrity, reducing scrap rates and saving costs. Lastly, the new water jet machine is known for its low operational costs over time, as it requires less energy compared to thermal alternatives and has a longer lifespan due to robust construction. These advantages make the new water jet machine a smart investment for businesses aiming to enhance quality and sustainability.

Applications of the New Water Jet Machine

The new water jet machine finds applications across a broad spectrum of industries, thanks to its adaptability and precision. In the manufacturing sector, it is used for cutting metal components, such as engine parts and structural elements, with high accuracy and speed. The automotive industry relies on the new water jet machine for prototyping and producing custom parts, as it can handle various materials without compromising strength. In architecture and construction, this machine excels at shaping stone, tiles, and glass for decorative and functional purposes, enabling intricate designs in countertops, flooring, and facades. The aerospace field benefits from the new water jet machine’s ability to cut lightweight composites and alloys without inducing stress cracks, which is crucial for safety-critical components. Additionally, the art and design community uses the new water jet machine to create detailed sculptures and installations from materials like wood and acrylic, pushing creative boundaries. Even in the food industry, specialized versions of the new water jet machine are employed for slicing products without contamination, highlighting its hygienic properties. This wide-ranging applicability underscores why the new water jet machine is a versatile tool for both industrial and creative endeavors.

Technological Innovations in the New Water Jet Machine

Recent advancements have propelled the new water jet machine into a new era of efficiency and user-friendliness. One major innovation is the integration of IoT (Internet of Things) capabilities, allowing for remote monitoring and predictive maintenance. Sensors in the new water jet machine collect data on performance metrics, such as pressure levels and nozzle wear, enabling proactive adjustments to prevent breakdowns. Another key development is the adoption of AI-driven software for path optimization, which calculates the most efficient cutting routes to minimize time and material usage. This not only boosts productivity but also reduces operational costs. The new water jet machine also features improved pump designs that enhance energy efficiency, lowering power consumption by up to 20% compared to older models. Furthermore, advancements in abrasive recycling systems have made the new water jet machine more eco-friendly by reusing materials and cutting down on waste. Enhanced safety features, such as automated shutdown mechanisms and ergonomic controls, ensure operator protection during high-pressure operations. These technological leaps make the new water jet machine a forward-thinking solution that aligns with Industry 4.0 trends, offering smarter, more connected manufacturing environments.

Cost-Effectiveness and ROI of the New Water Jet Machine

Investing in the new water jet machine can yield substantial returns, making it a cost-effective choice for many businesses. Initially, the purchase price might seem high, but the long-term savings are significant due to reduced material waste and lower energy consumption. For instance, the new water jet machine minimizes scrap by optimizing cut paths, which can lead to material savings of 10-15% annually. Additionally, its versatility eliminates the need for multiple specialized machines, consolidating equipment costs and floor space. Operational expenses are kept in check through efficient water and abrasive usage, with modern systems featuring recycling options that cut supply costs by half in some cases. Maintenance costs for the new water jet machine are relatively low, as durable components and self-diagnostic tools reduce the frequency of repairs. When calculating ROI, businesses often see payback within 1-2 years, thanks to increased production speeds and higher quality outputs that attract more clients. Case studies in various industries show that the new water jet machine can improve overall profitability by 20-30% by streamlining processes and reducing downtime. Thus, the new water jet machine is not just a tool but a strategic asset that enhances financial performance.

Maintenance and Safety Features of the New Water Jet Machine

Proper maintenance is crucial for maximizing the lifespan and performance of the new water jet machine. Routine tasks include checking the high-pressure pump for leaks, replacing nozzles and seals regularly, and cleaning the abrasive delivery system to prevent clogs. The new water jet machine often comes with automated maintenance alerts through its software, reminding users of service intervals based on usage data. This proactive approach helps avoid unexpected failures and extends the machine’s operational life. Safety is equally important, and the new water jet machine incorporates multiple features to protect operators. These include emergency stop buttons, pressure relief valves, and enclosed cutting areas that contain high-speed water jets. Training programs for handling the new water jet machine are recommended to ensure safe operation, covering topics like proper material handling and emergency procedures. Additionally, the machine’s design often includes noise reduction elements and splash guards to minimize workplace hazards. By adhering to maintenance schedules and safety protocols, users can ensure that the new water jet machine operates reliably and safely, reducing risks and maintaining high productivity levels.

Environmental Impact of the New Water Jet Machine

The new water jet machine is celebrated for its environmentally friendly attributes, aligning with global sustainability goals. Unlike thermal cutting methods that generate harmful emissions, the new water jet machine uses water as its primary cutting medium, producing no air pollutants or greenhouse gases. The water used in the process can often be recycled within closed-loop systems, minimizing consumption and reducing the strain on local water resources. Abrasives, such as garnet, are typically natural and non-toxic, and many models of the new water jet machine include recycling mechanisms that reclaim and reuse these materials, cutting waste by up to 80%. This not only lowers disposal costs but also lessens the environmental footprint. Energy efficiency is another highlight; modern pumps in the new water jet machine are designed to consume less electricity while maintaining high performance, contributing to lower carbon emissions. Furthermore, the cold-cutting process avoids the energy-intensive heating required in lasers or plasma cutters, making the new water jet machine a greener alternative. By adopting this technology, companies can enhance their eco-credentials and comply with stringent environmental regulations, all while achieving superior cutting results.

In conclusion, the new water jet machine represents a significant leap forward in cutting technology, offering precision, versatility, and sustainability that meet the demands of today’s industries. From its innovative workings and broad applications to its cost-effectiveness and environmental benefits, this machine proves to be a valuable investment. As technology continues to evolve, the new water jet machine is poised to become even more integral to manufacturing and beyond, driving efficiency and creativity. By understanding these seven key aspects, businesses can make informed decisions to integrate this tool into their operations, ultimately leading to improved outcomes and a competitive edge.

Frequently Asked Questions

Q1: What is the typical lifespan of a new water jet machine?

A1: The typical lifespan of a new water jet machine ranges from 10 to 15 years, depending on usage and maintenance. Regular servicing and proper operation can extend its life, with key components like pumps and nozzles requiring periodic replacement to ensure optimal performance.

Q2: Can the new water jet machine cut through thick materials?

A2: Yes, the new water jet machine can cut through materials up to 200 mm thick or more, depending on the type of material and the machine’s specifications. For instance, it easily handles thick metals, stone, and composites by adjusting pressure and abrasive flow rates.

Q3: How does the new water jet machine compare to laser cutters?

A3: The new water jet machine offers advantages over laser cutters in several ways: it produces no heat-affected zones, allowing for cuts in heat-sensitive materials, and it can handle a wider variety of materials, including reflective surfaces. However, laser cutters might be faster for thin metals, but the new water jet machine excels in versatility and safety.

Q4: What safety precautions are necessary when operating the new water jet machine?

A4: Key safety precautions include wearing protective gear like gloves and goggles, ensuring the cutting area is enclosed, and following emergency stop procedures. Regular training on handling high-pressure systems and maintaining a clean workspace is essential to prevent accidents with the new water jet machine.

Q5: Is the new water jet machine suitable for small businesses?

A5: Absolutely, the new water jet machine is scalable and can be adapted for small businesses, offering models with lower upfront costs and compact designs. Its efficiency and reduced waste can help small enterprises compete by improving product quality and lowering operational expenses over time.

continue reading

Related Posts

- 1077 words5.4 min read

- 1175 words5.9 min read

- 1255 words6.3 min read