7 Key Advantages of Small CNC Water Jet Cutters: Precision Power for Compact Workshops

The demand for versatile, high-precision cutting has exploded in small-scale manufacturing, prototyping, and artisan workshops. Enter the small CNC water jet cutter – a game-changing technology that packs the incredible power of waterjet cutting into a more accessible, space-efficient footprint. Unlike their massive industrial counterparts, these compact powerhouses bring unparalleled flexibility and capability right to the benchtop or small shop floor. Let’s dive into the seven key advantages that make a small CNC water jet cutter an indispensable tool for modern creators and fabricators.

1. Unmatched Versatility: Cutting Virtually Anything, Any Shape

The defining superpower of any water jet cutter, especially a small CNC water jet cutter, is its astonishing material versatility. This isn’t just about cutting metal; it’s about conquering a universe of materials with a single machine:

Metals: From delicate aluminum foil and thin copper sheets to tough stainless steel, titanium, and hardened tool steel (though slower on very thick, hard metals). No heat input means no Heat-Affected Zone (HAZ), preserving material properties and preventing warping or hardening. A small CNC water jet cutter excels at intricate parts for aerospace components, jewelry, and custom fittings.

Stone & Tile: Perfect for intricate mosaics, custom countertop cutouts (sinks, drainboards), signage, and decorative inlays without chipping or thermal cracking. Granite, marble, slate, porcelain – no problem.

Glass: Cutting thick or laminated glass for artistic panels, windows, shower enclosures, and decorative items with smooth edges and no micro-cracks induced by heat.

Composites: Ideal for carbon fiber, fiberglass, Kevlar, and laminates. The cold-cutting process prevents delamination, fraying, or resin melting common with laser or router cutting. Essential for aerospace, automotive, and sporting goods prototypes.

Plastics & Rubber: Acrylic (Plexiglas), polycarbonate, PVC, UHMW, neoprene, gaskets – all cut cleanly without melting, toxic fumes, or burrs.

Foams & Insulation: Precision cutting of packaging foams, architectural models (like blue foam), and insulation materials without compression or messy melt-back.

Exotics & Laminates: Materials like circuit boards, food products (in pure water mode), leather, and dense woods pose no challenge. A small CNC water jet cutter handles layered or dissimilar materials cleanly.

This “one machine for (almost) all materials” drastically simplifies workflow, reduces the need for multiple specialized cutters, and accelerates project turnaround in small shops.

2. Pinpoint Precision & Complex Geometry Capabilities

Driven by sophisticated CNC (Computer Numerical Control) systems, a small CNC water jet cutter achieves remarkable levels of precision and complexity:

Tight Tolerances: Capable of holding tolerances typically within ±0.001″ to ±0.005″ (0.025mm to 0.127mm) depending on material thickness and machine calibration. This rivals many machining processes for 2D profiles.

Intricate Details: The small, high-velocity stream (often starting around 0.010″ to 0.040″ / 0.25mm to 1.0mm diameter with abrasive) allows cutting incredibly complex shapes, sharp inside corners, fine text, and micro-details impossible for plasma or laser to replicate cleanly on many materials.

Kerf Characteristics: While waterjets do have a kerf (cut width), it’s relatively small and consistent. The small CNC water jet cutter’s precision ensures minimal material waste around intricate parts. Kerf compensation is handled automatically by the CNC software.

Near-Net-Shape Cutting: The precision allows parts to be cut very close to their final dimensions, minimizing or even eliminating secondary machining operations in many cases.

No Tool Wear (in the traditional sense): Unlike milling bits or router bits that dull and change diameter, the abrasive garnet is constantly renewed. This means the first part and the hundredth part have the same dimensional accuracy, provided machine calibration is maintained. The cutting head itself has wear parts (mixing tube, nozzle) but these are consumables replaced periodically.

This precision makes the small CNC water jet cutter ideal for prototypes, intricate artwork, precision gaskets, electronic enclosures, and specialized components requiring exact dimensions.

3. The Cold Cutting Advantage: Preserving Material Integrity

Perhaps the most significant advantage over thermal processes like laser, plasma, or oxy-fuel cutting is the complete absence of heat:

No Heat-Affected Zone (HAZ): Thermal processes alter the metallurgical structure near the cut edge, creating a HAZ. This zone can be hardened, weakened, discolored, or stressed. Waterjet cutting produces no HAZ, leaving the material’s original properties fully intact right up to the cut edge. This is critical for materials sensitive to heat (tempered metals, certain plastics) or where structural integrity is paramount.

No Thermal Distortion: Heat causes expansion and contraction, leading to warping, especially in thin materials or complex shapes. Cold cutting eliminates this distortion, ensuring parts remain flat and dimensionally stable.

No Hardened Edges: Metals cut with plasma or laser often develop a hardened edge that is difficult to machine further. Waterjet edges remain in their native state, ready for welding, bending, or other secondary processes without extra steps.

Safe for Hazardous Materials: Cutting materials that are flammable, explosive, or prone to toxic fume release when heated (like certain composites or coated metals) is safe with a waterjet, as no combustion occurs. The water stream also suppresses dust.

Clean, Burr-Free Edges: While a slight “striation” pattern is common, waterjet cuts typically produce edges with minimal to no burr, especially on thicker materials. Edges are often ready for use or require minimal finishing compared to plasma.

4. Space Efficiency, Accessibility, and Ease of Operation

The “small” in small CNC water jet cutter is a major selling point:

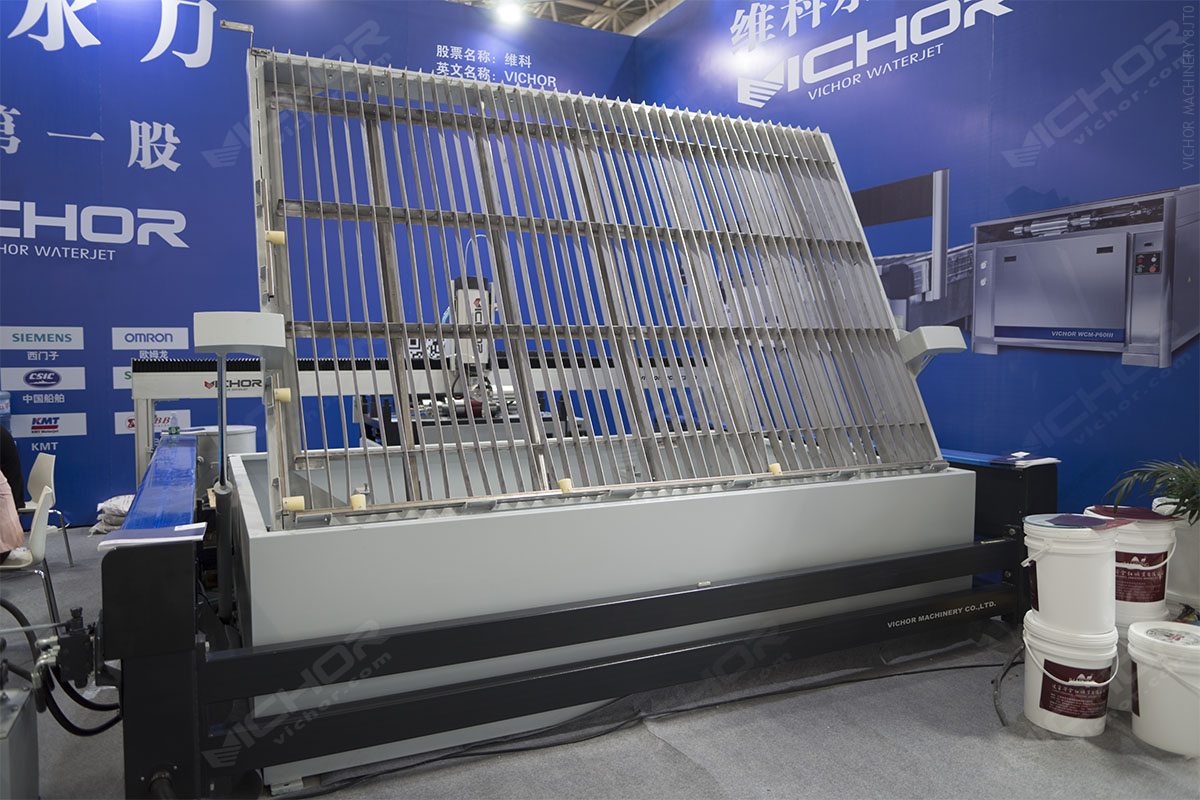

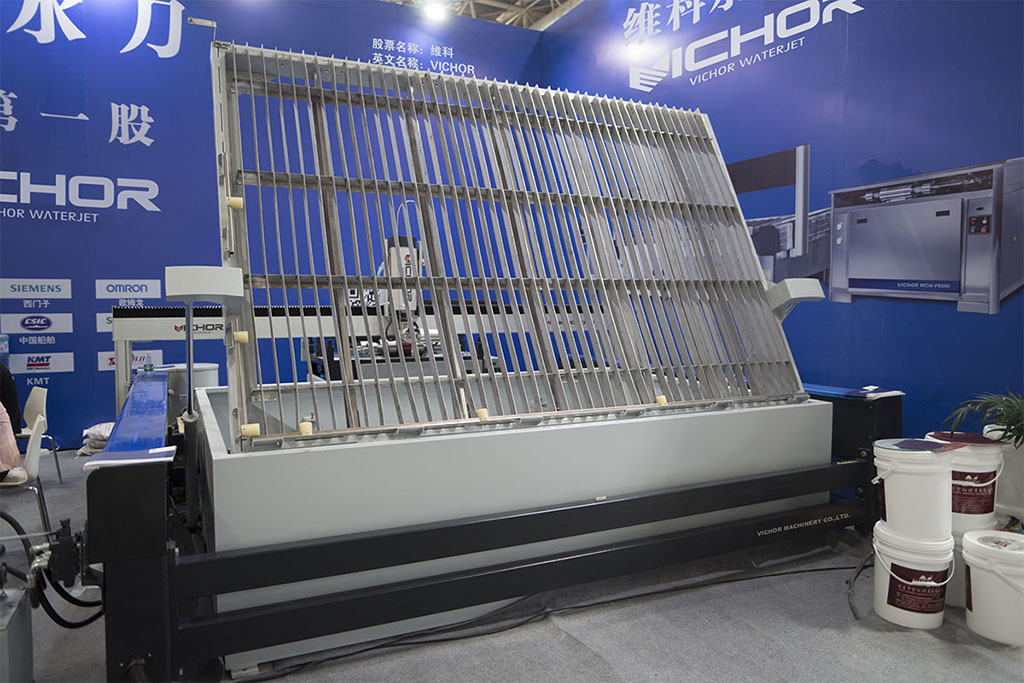

Compact Footprint: Designed specifically for smaller shops, garages, R&D labs, or educational institutions, these machines have significantly reduced footprints compared to industrial systems. They fit where large machines simply cannot.

Lower Entry Cost: While still a significant investment, the price point for a true small CNC water jet cutter is substantially lower than large industrial models, making the technology accessible to small businesses, startups, and serious hobbyists.

Simpler Infrastructure: Many small models are designed to run on standard single-phase 220V power (common in workshops/homes in many regions) and require less demanding water supply and drainage setups than their larger counterparts. Noise levels are also generally lower.

User-Friendly Software: Modern small CNC water jet cutter systems come with intuitive CAD/CAM software. Operators can often import standard DXF or DWG files, set cutting parameters (speed, pressure, abrasive rate), and generate toolpaths with relative ease. Training curves are much shorter than for complex multi-axis machining centers.

Reduced Operating Complexity: While maintenance is crucial (pump care, nozzle replacement), the day-to-day operation of loading material, running programs, and unloading parts is generally straightforward.

This accessibility democratizes a technology that was once only available to large manufacturers.

5. Cost-Effectiveness & Return on Investment (ROI)

While the initial purchase price needs consideration, the small CNC water jet cutter offers compelling ROI arguments, especially when viewed holistically:

Reduced Secondary Operations: Eliminating HAZ means no need for stress-relieving heat treatments. Minimal burring reduces or eliminates deburring time. High precision often means parts are finished right off the table.

Minimal Material Waste: Nesting software efficiently packs parts onto raw material sheets. The small kerf and ability to cut very close to edges further conserve expensive materials, especially exotics like titanium or composites.

Versatility = Consolidation: Replacing the need for multiple dedicated cutters (plasma for metal, router for composites, separate tile saw) saves significant capital expenditure, floor space, and operator training overhead. One small CNC water jet cutter handles diverse jobs.

Faster Job Turnaround: Quick setup (especially for different materials – just change abrasive or switch to pure water), rapid programming, and the ability to run unattended for many jobs mean faster completion times and the ability to take on more work.

Expanded Capabilities & Market Reach: The ability to offer intricate cuts in diverse materials opens up new markets and customer bases (e.g., custom signage, architectural features, specialized prototypes, art fabrication) that were previously inaccessible.

Reduced Consumable Costs (Compared to some): While abrasive garnet and wear parts (orifice, mixing tube) are ongoing costs, they are often less expensive than specialized laser gases or high-end router bits for composites, and significantly cheaper than wire EDM consumables.

6. Applications Tailored for Compact Power

The capabilities of a small CNC water jet cutter naturally lend themselves to specific, high-value applications:

Prototyping & R&D: Rapidly iterate designs across a vast material spectrum without heat damage. Test form, fit, and function with production-representative parts.

Custom Fabrication & Art: Create unique metal sculptures, intricate stone inlays, detailed acrylic displays, bespoke signage, and personalized gifts. The ability to cut complex shapes in diverse materials is unparalleled.

Aerospace & Defense Components: Precision cutting of titanium, aluminum, and advanced composites for brackets, shims, ducts, and non-structural parts, often meeting stringent requirements without HAZ.

Automotive & Motorsports: Crafting custom brackets, gaskets, heat shields, interior trim pieces, composite body panels, and specialized tools from relevant materials.

Electronics & Enclosures: Cutting precise openings in aluminum or plastic enclosures for displays, connectors, and ventilation without thermal damage to sensitive internal areas.

Kitchen & Bath: Custom sink cutouts in stone countertops, intricate tile designs, and decorative metal backsplashes.

Medical Devices & Instruments: Prototyping and small-batch production of stainless steel surgical tools, implant templates, and specialized components requiring biocompatibility and precision without thermal alteration.

Education & Maker Spaces: Providing students and makers with access to industrial-grade cutting technology for learning and innovation across engineering, design, and art disciplines.

7. Choosing the Right Small CNC Water Jet Cutter & Future Trends

Selecting the optimal small CNC water jet cutter requires careful consideration:

Cutting Envelope (Table Size): Match the X-Y cutting area to the typical size of your workpieces. Allow room for future needs.

Pump Pressure & Power: Higher pressure (e.g., 60,000 PSI vs. 40,000 PSI) enables faster cutting speeds and thicker material capability, but increases cost and complexity. HP rating correlates to cutting power.

Z-Axis (Cutting Head) Height & Control: Adequate height is needed for thick materials. Automatic height control (AHC) maintains optimal nozzle distance over uneven surfaces or warped plates, crucial for quality and consumable life.

Control System & Software: Evaluate the user interface, CAD/CAM compatibility, nesting capabilities, and ease of use. Look for features like collision avoidance.

Abrasive Delivery System: Reliable, consistent abrasive metering is vital for cut quality and efficiency.

Tank Design & Material Handling: Consider ease of loading/unloading, water management (filtration, decontamination), and waste (sludge) removal.

Reliability & Support: Research the manufacturer’s reputation, warranty, and availability of local service and technical support.

The Future is Compact and Connected:

Small CNC water jet technology continues to evolve:

Increased Automation: Integration with robotic part loading/unloading systems and automated abrasive/waste handling for lights-out production.

Enhanced Intelligence: AI-driven optimization for cutting parameters, predictive maintenance, and real-time quality monitoring.

Improved Efficiency: Developments in pump technology and nozzle design aim for higher cutting speeds and reduced abrasive consumption.

Hybrid Machines: Combining waterjet cutting with other processes like milling or drilling in a single compact platform.

Even Greater Accessibility: Continued refinement making these powerful tools even more user-friendly and cost-effective for smaller operations.

The small CNC water jet cutter is far more than just a scaled-down industrial tool. It represents a paradigm shift, bringing unprecedented versatility, cold-cutting precision, material integrity preservation, and operational accessibility to workshops and businesses of all sizes. Its ability to cut virtually any material into complex shapes with no heat distortion solves fundamental challenges faced by fabricators, artists, engineers, and designers. From accelerating prototyping to enabling custom fabrication and small-batch production, the advantages – versatility, precision, cold cutting, accessibility, and compelling ROI – make a small CNC water jet cutter a transformative investment. As technology advances, making these machines smarter, faster, and even more user-friendly, their role as essential powerhouses in the compact workshop is only set to grow. For anyone serious about expanding their fabrication capabilities without compromise, exploring the potential of a small CNC water jet cutter is a crucial step.

continue reading

Related Posts

- 1103 words5.6 min read

- 1111 words5.6 min read