5 Unbeatable Advantages of Waterjet Cutting Rubber for Precision Parts

In the vast world of manufacturing and fabrication, few materials are as ubiquitous and yet as challenging to cut cleanly as rubber. From durable gaskets and seals to custom vibration dampeners and protective pads, rubber components are critical in countless industries. Traditional cutting methods like die-cutting, laser cutting, and blade machining often fall short, leaving burned edges, distorted shapes, or costly tooling requirements. This is where a superior solution emerges: waterjet cutting rubber.

This cold-cutting process has revolutionized how engineers and fabricators handle elastomers. Whether you’re working with soft neoprene, dense polyurethane, or resilient nitrile, waterjet cutting rubber offers a unique combination of precision, versatility, and efficiency that is unmatched by other technologies. This article dives deep into the five undeniable advantages of using a waterjet for rubber, explaining why it has become the gold standard for producing high-quality, burr-free rubber parts.

1. The Perfect Cut: Why Waterjet is the Ideal Technology for Rubber

To understand why waterjet cutting rubber is so effective, we must first look at the fundamental challenges of cutting elastomers and how waterjet technology overcomes them.

The Challenges of Rubber:

Flexibility and Elasticity: Rubber stretches and deforms under pressure from traditional blade tools, leading to inaccurate cuts and misshapen parts.

Heat Sensitivity: Many rubbers are highly susceptible to heat. Laser cutting and ultrasonic knives can melt, burn, or vulcanize the edges, compromising the material’s integrity and creating toxic fumes.

Abrasion and Tearing: Hard tools can tear or fray the material, especially softer foams and sponges, resulting in a rough, unfinished edge that is unacceptable for precision seals.

The Waterjet Solution:

Waterjet cutting rubber utilizes a stream of ultra-high-pressure water (typically between 60,000 and 90,000 PSI) focused through a tiny gemstone orifice. For rubber, this almost always involves a pure waterjet process, meaning no abrasive grit is added. The stream is incredibly fine (around 0.004 inches in diameter) and moving at supersonic speeds.

This process is cold; it generates no heat, eliminating any risk of melting or heat-affected zones. It is also a non-contact process. The water stream exerts negligible lateral force on the material, so there is no crushing, stretching, or deformation of the rubber during cutting. The result is a perfectly clean, sharp, and accurate edge that maintains the rubber’s original properties throughout the entire cross-section.

2. Unmatched Precision and Complex Geometries

One of the most significant benefits of waterjet cutting rubber is its ability to produce incredibly intricate and precise designs with ease.

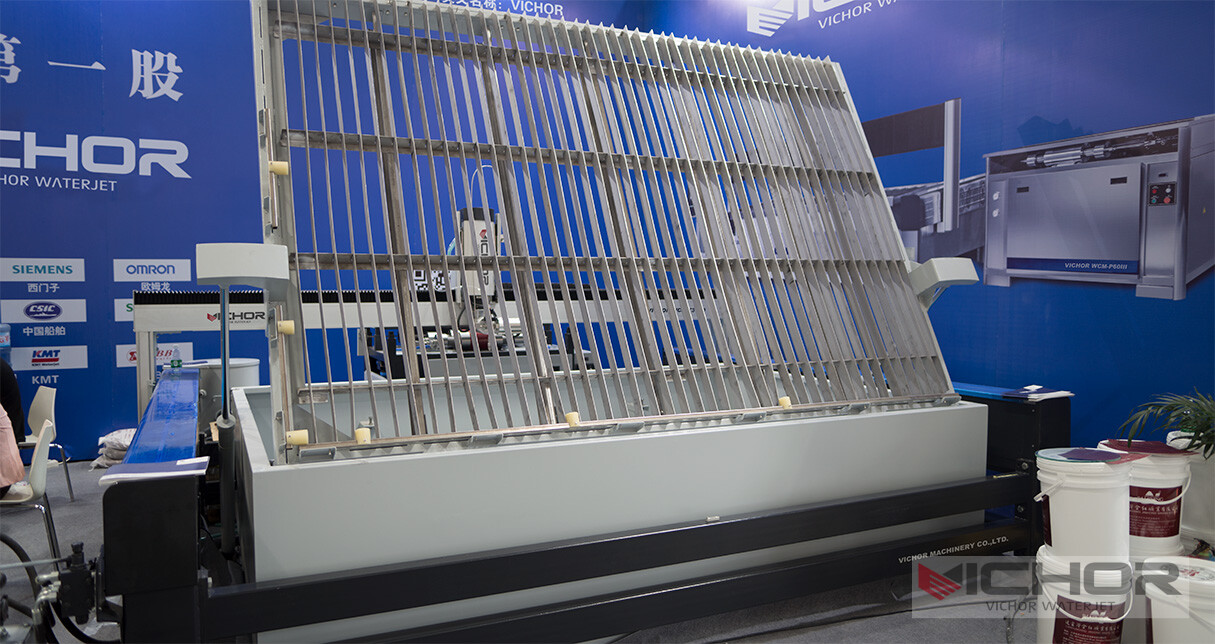

CNC Accuracy: The waterjet cutting head is mounted on a sophisticated CNC (Computer Numerical Control) gantry system. This means it follows a digital design file (like a DXF or DWG) with extreme accuracy, typically within a tolerance of ±0.005 inches. This level of precision is impossible to achieve consistently with manual die-cutting or blade methods.

Complexity Without Cost Penalty: Unlike die-cutting, which requires expensive custom tooling for each new shape, waterjet cutting requires only a digital file change. This makes it ideal for:

Prototyping: You can cut a single, complex part without investing thousands of dollars in a die.

Low-Volume Production: Perfect for short runs where the cost of a die is unjustifiable.

Customization: Easily produce unique, one-off parts or quickly iterate on designs.

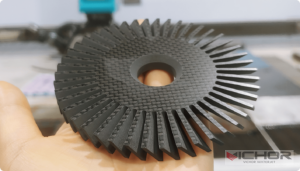

Intricate Features: Waterjets can effortlessly cut small holes, sharp corners, intricate curves, and fine details that would tear, burn, or be impossible to achieve with other methods. This allows designers unprecedented freedom when creating rubber components.

3. Material Versatility: Cutting More Than Just Standard Rubber

The term “rubber” encompasses a massive range of materials with different hardnesses, densities, and compositions. A key advantage of waterjet cutting rubber is its ability to handle them all on the same machine, without any tool changes.

A waterjet can cleanly cut virtually any elastomer or polymer sheet, including:

Neoprene: For wetsuits and gaskets.

Nitrile (Buna-N): For fuel and oil-resistant seals.

EPDM Rubber: For automotive and outdoor applications.

Silicone: For medical and food-grade products.

Viton: For high-temperature and chemical-resistant seals.

Polyurethane: For high-abrasion resistance parts.

Butyl Rubber: For excellent vibration damping.

Cork and Cork-Rubber Composites: For gaskets and insulation.

Sponge and Foam Rubbers: From soft packaging foam to dense closed-cell materials.

This versatility means a single waterjet cutting rubber service or machine can fulfill all your elastomer cutting needs, streamlining your supply chain and reducing reliance on multiple specialized vendors.

4. Cost-Effectiveness and Efficiency for Projects of Any Size

While the initial perception might be that waterjet is an expensive technology, it is often the most cost-effective solution for waterjet cutting rubber, especially when you consider the total cost of ownership and production.

No Tooling Costs: This is the most substantial saving. The cost of designing, machining, and maintaining hard tooling like dies and punches can run into thousands of dollars and take weeks to produce. Waterjet eliminates this entirely. Your only “tool” is a digital file, which can be created or modified in minutes at a negligible cost.

Reduced Material Waste: Advanced nesting software allows the CNC system to arrange parts from multiple jobs on a single sheet of rubber with extreme efficiency. This minimizes scrap material and maximizes your yield from each expensive sheet of material.

Fast Turnaround: The combination of no tooling and digital workflow means parts can be produced in hours or days, not weeks. This accelerates prototyping cycles and allows for just-in-time manufacturing, reducing inventory costs.

Low Volume to High Volume: While perfect for prototyping, waterjets are also highly efficient for production. Modern machines can run unattended for long periods, cutting large batches of parts with consistent quality.

5. Superior Edge Quality and Environmental Benefits

The final product quality is what matters most, and waterjet cutting rubber delivers a finish that is functionally and aesthetically superior.

Clean, Sealed Edges: The high-pressure water stream produces a smooth, clean edge that is often “sealed.” This is particularly important for seals and gaskets, as a rough edge can be a initiation point for tearing or can compromise the seal. There is no fraying, tearing, or delamination.

No Post-Processing: Unlike laser cutting (which leaves a burned, hardened edge) or blade cutting (which can leave a ragged edge), waterjet-cut rubber parts are often ready to use straight off the machine. This eliminates secondary finishing operations like sanding or degreasing, saving additional time and labor costs.

Environmental and Safety Advantages:

No Fumes: The cold-cutting process creates no harmful fumes or vapors, unlike hot cutting methods that can release toxic chemicals from certain synthetic rubbers. This creates a safer working environment for operators.

No Contamination: Pure waterjet cutting uses only water, so there is no risk of oil or grease contamination from cutting tools, which is crucial for medical and food-grade applications.

Eco-Friendly: The water used is typically filtered and recirculated in a closed-loop system, minimizing consumption. The only waste is the tiny amount of rubber removed during the cut, which is non-hazardous.

When the requirements call for precision, cleanliness, versatility, and cost-efficiency, the choice is clear. Waterjet cutting rubber is not just an alternative method; it is the optimal solution for modern manufacturing challenges. It empowers designers to push the boundaries of what’s possible with elastomers, enables businesses to respond with agility to market demands, and delivers a finished product of unmatched quality. Whether you are a design engineer prototyping a new concept or a production manager sourcing critical seals, embracing the power of waterjet technology will transform your approach to working with rubber.

continue reading

Related Posts

- 1077 words5.4 min read

- 1175 words5.9 min read

- 1255 words6.3 min read