5 Revolutionary Benefits of Water Jet Meat Cutting in Modern Food Processing

Imagine a technology that slices through meat with the precision of a surgeon’s scalpel, yet uses nothing more than water. That’s the reality of water jet meat cutting, a method that’s transforming how the food industry handles one of its most fundamental tasks. In an era where efficiency, hygiene, and sustainability are paramount, this innovative approach is gaining traction for its ability to deliver consistent results without the drawbacks of traditional methods. Whether you’re in meat processing, packaging, or simply curious about food tech advancements, understanding water jet meat cutting can offer insights into a cleaner, smarter future. This article dives deep into five key aspects that make this technology a game-changer, from its operational mechanics to its broad applications. Let’s explore how harnessing the power of water is reshaping meat cutting as we know it.

What Is Water Jet Meat Cutting and How Did It Evolve?

Water jet meat cutting is a non-thermal cutting process that utilizes high-pressure water streams, often mixed with abrasive materials, to slice through various types of meat with exceptional accuracy. Unlike conventional blades or saws, this method relies on the force of water ejected at speeds exceeding Mach 3, capable of cutting through bone, fat, and muscle without generating heat. This prevents cooking or denaturing the meat, preserving its natural texture and nutritional value. The concept dates back to industrial applications in the 1970s, where water jets were used for cutting materials like metal and stone. Over time, advancements in pump technology and hygiene protocols allowed its adaptation to the food sector, particularly in meat processing. Today, water jet meat cutting is recognized for its versatility, handling everything from tender poultry to tough beef cuts. As food safety standards tighten, this method has emerged as a reliable solution, minimizing cross-contamination risks and extending shelf life. Its evolution reflects a broader shift toward automated, precision-based systems in food production, making it a cornerstone of modern processing facilities.

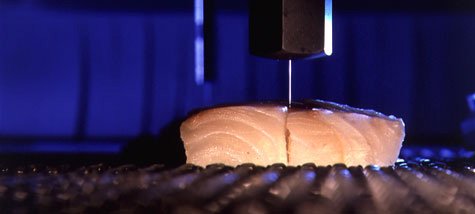

How Does the Technology Behind Water Jet Meat Cutting Work?

The core mechanism of water jet meat cutting involves a high-pressure pump that pressurizes water to levels ranging from 50,000 to 90,000 psi (pounds per square inch). This pressurized water is then forced through a small nozzle, typically made of sapphire or diamond, creating a fine, coherent jet that can be directed onto the meat surface. In many systems, abrasives like garnet are added to the stream to enhance cutting efficiency, especially for denser materials like bone or frozen meat. The entire process is controlled by computerized numerical control (CNC) systems, which guide the nozzle along predefined paths to achieve precise cuts, such as portioning steaks or deboning joints. One of the standout features is the absence of heat generation; since no blades are involved, there’s no friction-induced warming that could alter the meat’s quality. Additionally, the water used is often sterilized or treated to meet food-grade standards, ensuring that the cutting environment remains sanitary. This technology not only boosts accuracy but also reduces waste by optimizing cut patterns, leading to higher yields. For instance, in large-scale processing plants, water jet meat cutting can handle high volumes while maintaining consistency, making it ideal for standardized products like pre-packaged meats.

Key Advantages of Adopting Water Jet Meat Cutting

The adoption of water jet meat cutting brings numerous benefits that address common challenges in the food industry. First, it offers unparalleled precision, allowing for clean, intricate cuts that minimize product loss. This is crucial for maximizing yield and profitability, as even minor improvements in cutting accuracy can translate to significant savings. Second, hygiene is a major advantage; the continuous flow of water washes away debris and bacteria during cutting, reducing the risk of contamination compared to traditional blades that can harbor pathogens. Third, water jet meat cutting is versatile, capable of handling various meat types—from soft poultry to hard bones—without requiring tool changes. This flexibility streamlines operations in diverse processing environments. Fourth, it enhances food safety by eliminating metal-to-meat contact, which can introduce foreign particles or allergens. Finally, this method supports sustainability by using water efficiently—often recycled within closed-loop systems—and reducing energy consumption compared to thermal alternatives. Collectively, these advantages make water jet meat cutting a cost-effective and future-proof choice for processors aiming to meet evolving consumer demands for quality and safety.

Applications of Water Jet Meat Cutting in the Food Industry

Water jet meat cutting finds extensive applications across the food sector, particularly in high-volume processing facilities. One primary use is in portion control, where it precisely cuts meat into uniform sizes for retail packaging, ensuring consistency in weight and appearance. This is vital for brands that prioritize customer satisfaction and regulatory compliance. Another application is in deboning and trimming, where the technology separates bone from meat with minimal residue, improving efficiency in operations like chicken or pork processing. Additionally, water jet meat cutting is employed in value-added product lines, such as creating specialty cuts for gourmet foods or ready-to-eat meals. Its ability to handle frozen meat without thawing is another key application, reducing processing time and preserving product integrity. In recent years, it has also been integrated into automated production lines, working alongside robotics to enhance throughput. Beyond commercial settings, this method is gaining traction in niche areas like artisanal butchery and research institutions, where precision is paramount. As the food industry continues to innovate, water jet meat cutting is poised to expand into new domains, such as plant-based meat alternatives, where similar cutting challenges exist.

Comparing Water Jet Meat Cutting to Traditional Methods

When compared to traditional meat cutting methods—such as band saws, knives, or laser cutters—water jet meat cutting stands out for its unique combination of safety, efficiency, and quality. Band saws, for example, rely on mechanical blades that can generate heat, leading to meat degradation and increased risk of bacterial growth due to residue buildup. In contrast, water jet systems operate without direct contact, minimizing contamination and preserving the meat’s natural state. Knife-based cutting, while versatile, is labor-intensive and prone to human error, resulting in inconsistent cuts and higher waste. Water jet meat cutting automates this process, ensuring repeatability and reducing reliance on skilled labor. Laser cutting, though precise, often produces heat-affected zones that can cook the meat’s edges, altering its texture and nutritional profile. Water jet methods avoid this entirely, making them superior for heat-sensitive products. Economically, while the initial investment in water jet equipment may be higher, the long-term benefits—such as lower maintenance costs, reduced waste, and improved hygiene—often justify the expense. Overall, this comparison highlights why water jet meat cutting is increasingly preferred in modern food processing, offering a balanced approach that traditional methods struggle to match.

The Future Trends and Innovations in Water Jet Meat Cutting

The future of water jet meat cutting is bright, driven by technological advancements and growing industry demands. One emerging trend is the integration of artificial intelligence (AI) and machine learning to optimize cutting paths in real-time, further reducing waste and enhancing precision. For instance, AI algorithms can analyze meat structures to determine the most efficient cut patterns, adapting to variations in size or density. Another innovation involves eco-friendly improvements, such as developing water recycling systems that minimize consumption and incorporate biodegradable abrasives. As sustainability becomes a core focus, these enhancements will make water jet meat cutting even more appealing. Additionally, we’re seeing a push toward compact, modular systems that cater to smaller processors or butchers, democratizing access to this technology. Research is also underway to combine water jets with other non-thermal methods, like ultrasound, for synergistic effects in meat tenderization and safety. With the global meat processing market expanding, water jet meat cutting is set to play a pivotal role in meeting the need for faster, cleaner, and more efficient production. By staying ahead of these trends, businesses can leverage this technology to gain a competitive edge in an increasingly dynamic industry.

In summary, water jet meat cutting represents a significant leap forward in food processing, offering benefits that span precision, hygiene, and sustainability. From its sophisticated technology to its diverse applications, this method addresses many limitations of traditional cutting techniques. As the industry evolves, embracing innovations like water jet meat cutting can lead to higher quality products, reduced environmental impact, and enhanced operational efficiency. Whether you’re a processor, distributor, or consumer, understanding these advantages underscores the importance of adopting forward-thinking solutions in the food chain.

Frequently Asked Questions About Water Jet Meat Cutting

Q1: What exactly is water jet meat cutting?

A1: Water jet meat cutting is a technology that uses high-pressure water streams, sometimes combined with abrasives, to cut meat products without generating heat. This method ensures precise, clean cuts while maintaining the meat’s natural quality and reducing contamination risks.

Q2: How does water jet meat cutting improve food safety?

A2: It enhances food safety by eliminating direct contact between metal tools and meat, which minimizes the risk of bacterial cross-contamination. The continuous water flow also washes away debris during cutting, promoting a cleaner processing environment.

Q3: Can water jet meat cutting handle all types of meat, including frozen products?

A3: Yes, water jet meat cutting is highly versatile and can process various meats, such as beef, poultry, and pork, including frozen items. It avoids the need for thawing, which helps preserve texture and reduces processing time.

Q4: What are the cost implications of switching to water jet meat cutting?

A4: While initial setup costs can be higher than traditional methods, water jet meat cutting often leads to long-term savings through reduced waste, lower labor costs, and improved efficiency. The return on investment is typically realized via higher yields and enhanced product quality.

Q5: How does water jet meat cutting compare to laser cutting for meat?

A5: Unlike laser cutting, which can generate heat and alter meat properties, water jet meat cutting is a cold process that preserves the meat’s integrity. It also tends to be more hygienic and adaptable to different meat densities without the risk of burning or discoloration.

continue reading

Related Posts

- 1077 words5.4 min read

- 1175 words5.9 min read

- 1255 words6.3 min read