5 Factors That Determine Your Water Jetting Cost

If you’re looking at waterjet cutting for a project, one question tops the list: what will it cost? The water jetting cost isn’t a single number. It’s a calculation based on several clear, tangible factors. Understanding these factors helps you budget accurately and even find ways to save money.

Some shops quote by the hour, others by the inch of cutting, and some by the part. It can feel confusing. This breakdown will show you exactly what drives the price. Whether you’re comparing services or planning to buy a machine, knowing these elements is crucial.

We’ll move beyond a simple price list. We’ll explain why cutting thick steel costs more than thin aluminum, and how your design choices directly impact your final invoice.

The Core Drivers of Waterjet Cutting Expense

Every water jet service cost is built on a few foundational elements. These are the non-negotiable inputs that every job requires.

Material is the first major factor. The type and thickness directly affect water jet cutting price. Cutting 2-inch titanium is far more expensive than cutting 1/4-inch acrylic. The material cost itself is also passed through.

Cut time is the heart of the operational expense. The longer the machine runs, the higher the cost. Time is influenced by material thickness, hardness, and the complexity of your cut path. A simple circle is fast. An intricate, detailed pattern with sharp corners slows the head down, increasing time.

Setup and programming time is part of the quote. This includes preparing the file, nesting parts on the sheet, and securing the material to the table. For simple jobs, this is minimal. For complex, multi-part runs, it’s a more significant portion of the water jetting cost.

Machine and Consumable Costs: The Hidden Variables

When a shop calculates your rate, they are covering their own operating expenses. These are the “hidden” factors behind your water jetting price.

Abrasive garnet is the largest consumable cost. It’s used by the pound in abrasive cutting. Harder, thicker materials consume more garnet faster. The price of this garnet is a key component of your per-hour or per-part cost.

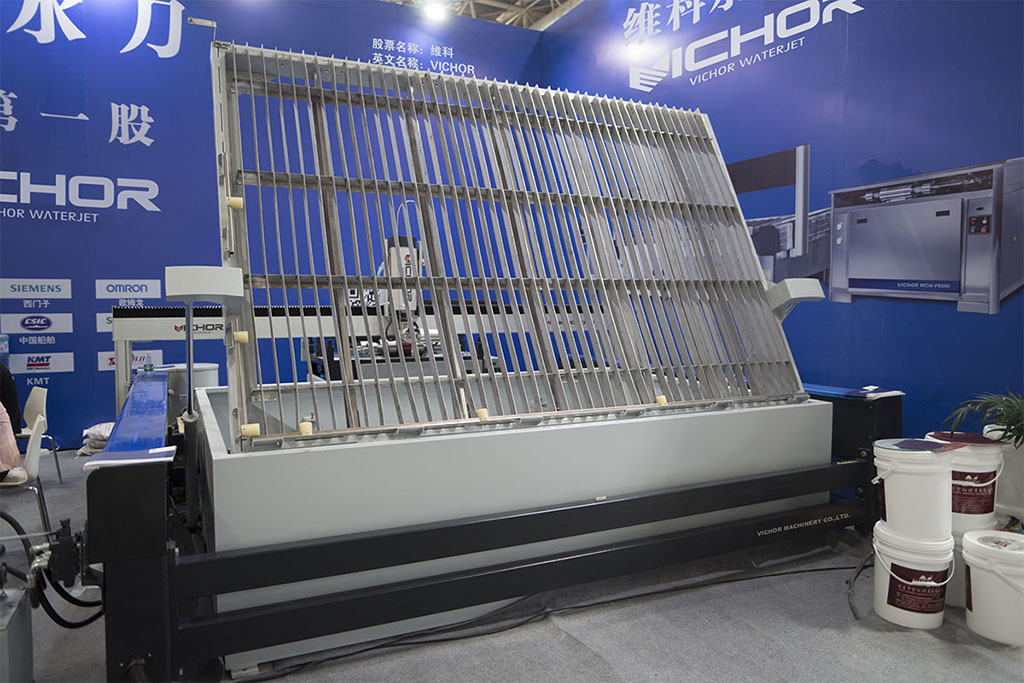

Machine wear and electricity are bundled in. High-pressure pumps from brands like VICHOR are robust, but seals, nozzles, and other parts wear out. The electricity to run a 50+ horsepower pump and motion system is significant. Your job share helps cover this.

Labor and overhead round it out. An operator oversees the process, handles material, and performs quality checks. The shop’s facility, insurance, and software licenses all factor into the final rate they charge.

Comparing Service Models: Job Shop vs. Online

How you procure the service changes the water jet cutting cost structure. The two primary models are traditional job shops and online instant-quote services.

A local job shop is great for complex projects requiring consultation. You might discuss material selection, tolerances, and finishing. Their pricing may be more flexible for large volume. The cost of water jet service here often includes a higher degree of personalized engineering support.

Online waterjet services offer transparent, automated pricing. You upload a CAD file, select material, and get an instant quote. This model is highly efficient for standard materials and well-defined parts. The online water jet cutting cost is usually very competitive for prototypes and short runs, with clear upfront numbers.

Material Type and Thickness: The Primary Cost Multipliers

This relationship is straightforward but critical. The water jetting cost per hour is directly tied to how fast the machine can move through your specific material.

Softer, thinner materials (like rubber, foam, or thin aluminum) cut very quickly. The machine head can move at high speed, resulting in a lower total cut time and cost.

Harder, thicker materials (like tool steel, titanium, or thick granite) force a slower cutting speed. The stream needs more time to penetrate. This slower speed, combined with higher abrasive consumption, makes the water jet cutting price per inch significantly higher.

Always provide your service provider with exact material specs. A generic “steel” quote can be misleading if they assume mild steel and you need hardened steel.

The Impact of Part Complexity and Tolerances

Your design decisions have a direct dollar impact. Simplifying a design can dramatically reduce water jetting cost.

Intricate designs with many curves, sharp corners, or small holes require slower cutting speeds to maintain accuracy. Each direction change causes a tiny pause. This “slowing down for detail” adds up in machine time.

Tight tolerances also increase cost. Holding a part to ±0.002″ requires more precise calibration, slower cutting, and more detailed inspection than a standard ±0.010″ tolerance. If your application allows for standard tolerances, you will save money.

Part nesting efficiency matters. A service provider can nest multiple parts from different customers on a single sheet of material. Good nesting minimizes wasted material, which can help keep your overall water jet service cost down.

Total Cost of Ownership vs. Service Cost

If you’re considering purchasing a machine, the water jetting cost analysis shifts entirely. You move from a per-job expense to a capital investment calculation.

The upfront price of a machine from a manufacturer like VICHOR is just the beginning. You must factor in installation, training, and annual maintenance contracts.

Then come the ongoing operational costs: electricity, abrasive garnet, replacement parts (orifice, focusing tube, seals), and labor for the operator. The cost to run a water jet per hour is a key metric for internal job costing.

The benefit is the elimination of markup and greater control. For businesses with consistent, high-volume work, owning a machine can lower the long-term water jet cutting cost per part.

How to Get an Accurate Quote and Reduce Expenses

To control your water jetting cost, be an informed customer. Providing clear information is the first step to an accurate quote.

Always supply a clean, ready-to-cut CAD file (DXF or DWG). This reduces their programming time and avoids errors. Specify the exact material type, grade, and thickness.

Discuss acceptable tolerances and edge quality needs. Do you need a finish-ready edge, or is some edge taper acceptable? A “rough cut” for a functional bracket costs less than a precision-cut for a visible component.

Ask about volume discounts. If you have a recurring part, inquire about contract pricing. Good partners, like VICHOR, will work with you to optimize the process for cost savings over the long term.

Frequently Asked Questions (FAQs)

Q1: What is the average cost per hour for waterjet cutting?

A1: There’s no single “average” as it varies by region, shop, and machine capability. However, industrial abrasive waterjet cutting services often range from $75 to $150+ per machine hour. Pure waterjet cutting for soft materials is typically less. Always get a quote based on your specific part for accuracy.

Q2: Is waterjet cutting more expensive than laser or plasma?

A2: It depends. For thin carbon steel, plasma is usually cheaper. For thin, non-metallic materials, laser can be faster and cheaper. Water jetting cost becomes very competitive for thick materials (over 1/2 inch), mixed materials, or heat-sensitive materials where laser and plasma cause damage. Its versatility often justifies the price.

Q3: Does the brand of the waterjet machine affect the service cost?

A3: Indirectly, yes. A shop with high-performance, reliable equipment from a brand like VICHOR may achieve faster cutting speeds and higher uptime. This efficiency can allow them to offer competitive rates or better consistency, which translates to value for your money, even if the hourly rate is similar to a shop with older machines.

Q4: Can I reduce cost by supplying my own material?

A4: Often, yes. Many job shops will reduce the quote if you provide the raw material, as it removes their purchase cost and inventory risk. However, ensure your material is flat, free of defects, and precisely the specified size. Not all shops offer this option, so it’s best to ask upfront.

Q5: Why do some online quotes seem much lower than others?

A5: Be cautious of quotes that seem too good to be true. Extremely low online water jet cutting cost might use lower-quality abrasive, have less rigorous quality control, or exclude setup and handling fees. A reputable provider like VICHOR will offer a transparent, all-inclusive quote that ensures you know exactly what you’re paying for.

continue reading

Related Posts

- 1077 words5.4 min read

- 1175 words5.9 min read

- 1255 words6.3 min read