4x8 Waterjet Cutting: The Ultimate Guide to Capabilities, Benefits, and Applications

In the world of precision cutting, versatility reigns supreme. Few technologies embody this principle as effectively as the 4×8 waterjet. This workhorse of the fabrication industry refers to a waterjet cutting machine specifically designed to handle standard-sized sheet materials – 4 feet wide by 8 feet long (approximately 1.22 meters by 2.44 meters). This size is ubiquitous across countless industries, making the 4×8 waterjet an incredibly common and practical configuration. But what makes this specific platform so vital? This comprehensive guide dives deep into the 4×8 waterjet, exploring its capabilities, advantages, applications, and why it might be the perfect solution for your cutting needs.

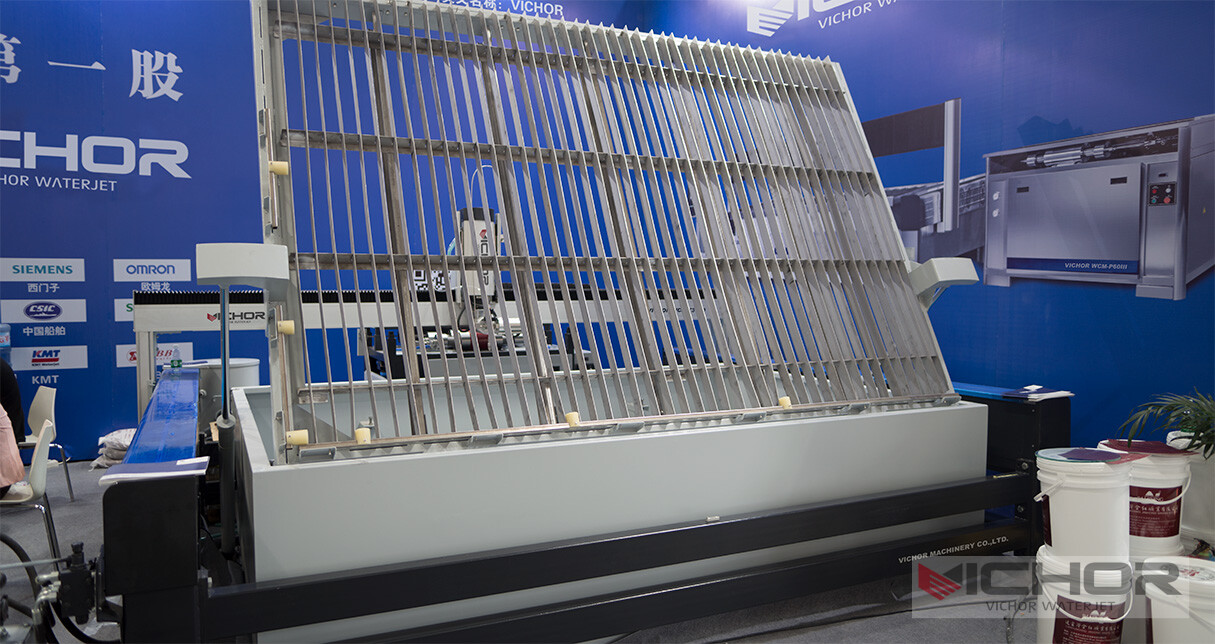

What is a 4×8 Waterjet?

At its core, a 4×8 waterjet is a computer numerically controlled (CNC) machine that uses an ultra-high-pressure stream of water, often mixed with an abrasive garnet, to cut through virtually any material. The defining characteristic is its cutting bed size, optimized to accommodate standard 4×8 foot sheets of material like metal (steel, aluminum, titanium, brass), stone (granite, marble), glass, plastic, composites, rubber, foam, and more. This standardization streamulates material handling, nesting (arranging parts efficiently on the sheet), and overall workflow for countless common projects. The machine precisely moves the cutting head (or the material) along the X and Y axes over the 4×8 foot area based on digital CAD/CAM instructions.

The Core Advantages of the 4×8 Waterjet Platform

The popularity of the 4×8 waterjet stems from a powerful combination of advantages inherent to waterjet technology itself, amplified by the practicality of the standard bed size:

Unmatched Material Versatility: This is the hallmark of waterjet cutting. A single 4×8 waterjet can seamlessly switch between cutting hardened tool steel, delicate acrylic, intricate titanium parts, thick granite countertops, and soft foam gaskets – all without changing tools or processes. The cold-cutting nature (no heat-affected zone) ensures material integrity is preserved.

Precision and Complex Geometry: Waterjets excel at cutting intricate shapes, sharp corners, and fine details with high accuracy (typically within +/- 0.003″ to +/- 0.005″). The kerf (cut width) is narrow, minimizing material waste, especially when nesting parts closely. This precision is consistent across the entire 4×8 cutting envelope.

No Heat-Affected Zone (HAZ): Unlike laser or plasma cutting, waterjet uses no heat. This eliminates thermal distortion, hardening, or weakening of the material along the cut edge. It’s crucial for heat-sensitive materials like plastics, tempered glass, and exotic metals where metallurgical properties must remain unchanged.

Minimal Mechanical Stress: The cutting force exerted by the waterjet stream is relatively low compared to mechanical methods like milling or punching. This allows cutting very thin or fragile materials without distortion or damage.

Efficiency with Standard Sizes: The 4×8 waterjet bed is perfectly matched to the most common sheet stock size globally. This significantly reduces material waste compared to cutting smaller parts on oversized machines or needing to splice smaller sheets together for larger parts. Loading full sheets is streamlined.

Environmentally Friendlier: The primary cutting media is water and natural garnet abrasive. The process generates no hazardous fumes or gases (unlike some thermal processes) and the used abrasive garnet, while requiring disposal, is inert. Water is often recycled within the system.

Technical Capabilities of a 4×8 Waterjet

Understanding the practical limits of a 4×8 waterjet is key to leveraging its potential:

Cutting Thickness: While capable of cutting very thin materials (fractions of a millimeter), the practical upper limit on a standard 4×8 waterjet with a high-pressure pump (typically 60,000-90,000+ PSI) is generally:

Metals: Up to 6-10 inches (150-250mm) for softer metals like aluminum, up to 4-6 inches (100-150mm) for harder steels/titanium. Thicker cuts are possible but slower.

Stone: Up to 3-4 inches (75-100mm) for granite/marble is common, thicker with specialized setups.

Glass: Up to 2-3 inches (50-75mm).

Plastics/Composites: Can cut very thick sections (several inches) effectively.

Cutting Speed: Speed varies dramatically based on material type, thickness, desired edge quality, and pump pressure. Thin materials cut very quickly, while thick, dense materials are significantly slower. Generally, speeds range from inches per minute (IPM) for thick metals to feet per minute (FPM) for thin materials or softer substances.

Edge Quality: Waterjets produce a smooth, sandblasted-like finish on the cut edge. The finish quality can be adjusted:

Quality Cut: Slower speed, finer finish near the top, slightly tapered edge (more noticeable in thicker materials).

Production Cut: Faster speed, slightly rougher finish, more pronounced taper. Secondary machining is rarely needed for most applications, but can be done if a perfectly square edge is critical.

Taper Compensation: Advanced 4×8 waterjet CNC controls include software algorithms to dynamically adjust the cutting head angle or toolpath to compensate for the natural taper that occurs in thicker materials, resulting in straighter side walls.

Dynamic Water Control: Modern systems can automatically adjust water pressure on-the-fly during a cut, optimizing speed and quality for different sections of a part or different materials within a single sheet.

Materials Perfectly Suited for 4×8 Waterjet Cutting

The 4×8 waterjet shines because it handles the vast array of materials commonly supplied in 4×8 sheets:

Metals: Steel (mild, stainless, tool), Aluminum (alloys, plate, sheet), Copper, Brass, Bronze, Titanium, Inconel, Hastelloy. Excellent for prototypes, machine parts, architectural features, signage.

Stone & Tile: Granite, Marble, Slate, Limestone, Travertine, Porcelain Tile, Engineered Stone. Ideal for countertops (kitchen, bath), intricate inlays, fireplace surrounds, wall cladding, signage.

Glass: Float glass, Tempered glass (pre-cut before tempering), Laminated glass, Mirrors. Used for decorative panels, dividers, shower enclosures, furniture components, art.

Plastics & Composites: Acrylic (Plexiglas), Polycarbonate, PVC, ABS, HDPE, G10/FR4, Carbon Fiber, Fiberglass, Kevlar. Perfect for displays, machine guards, prototypes, gaskets, aerospace components, automotive parts.

Rubber & Foam: Neoprene, Urethane, Silicone, EPDM, Polyurethane Foam, Polystyrene Foam. Used for seals, gaskets, insulation, packaging, flotation devices, models.

Specialty Materials: Laminates (Formica, etc.), Wood (though less common than other methods), Ceramics, Food products (in specialized applications).

Key Applications Leveraging the 4×8 Waterjet

The combination of versatility, precision, and standard sheet handling makes the 4×8 waterjet indispensable across numerous sectors:

Metal Fabrication & Job Shops: Cutting intricate brackets, flanges, gears (prototypes), machine components, tooling plates, decorative panels, architectural metalwork (screens, railings), and efficiently nesting parts from standard sheets.

Aerospace & Defense: Cutting high-strength alloys (titanium, Inconel), composites (carbon fiber), honeycomb structures, and specialty materials for components where no HAZ is critical. Prototyping complex parts is a major use case.

Architecture, Construction & Interior Design: Fabricating intricate stone countertops, vanity tops, backsplashes, wall tiles, and decorative inlays. Cutting metal cladding, decorative screens, stair treads, and signage. Creating custom glass partitions, shower doors, and decorative panels.

Signage & Displays: Cutting letters, logos, and intricate shapes from metals (aluminum, brass), acrylics, PVC, foams, and composites for indoor/outdoor signage, point-of-purchase displays, trade show booths, and dimensional letters.

Automotive & Transportation: Prototyping parts, cutting gaskets and seals, fabricating interior components (plastic trim, composite panels), and cutting specialized materials for aftermarket or custom parts.

Manufacturing & Industrial: Producing jigs, fixtures, templates, wear plates, insulators, and components from a wide range of materials. Cutting gaskets and seals on-demand.

Art & Sculpture: Enabling artists to cut incredibly detailed designs in stone, metal, glass, and other materials that would be difficult or impossible with other methods. The cold cut preserves material integrity.

Why Choose a 4×8 Waterjet Over Other Cutting Methods?

While lasers, plasma cutters, routers, and punches all have their place, the 4×8 waterjet offers unique benefits:

vs. Laser Cutting: Waterjet wins on material versatility (cuts reflective materials like copper/brass and non-conductive materials like stone/glass that lasers struggle with), thicker material capability (especially non-metals), and no HAZ. Lasers are generally faster on thinner metals and offer a finer kerf on thin sheets.

vs. Plasma Cutting: Waterjet provides vastly superior precision, edge quality (no dross), and the ability to cut non-conductive materials. Plasma is generally faster and cheaper for thicker carbon steel profiles where precision is less critical. Plasma creates a significant HAZ.

vs. CNC Routing/Milling: Waterjet is faster for profile cutting, generates no dust (a major advantage), and handles harder materials like stone and metal easily. Routers excel at true 3D contouring, drilling, and machining features requiring specific edge finishes (chamfers, pockets) that waterjet doesn’t create.

vs. Punching: Waterjet requires no expensive tooling, allows for infinite shape complexity and last-minute design changes, and handles thick materials beyond punch capacity. Punching is much faster for high-volume production of simple shapes in sheet metal when tooling costs are amortized.

Considerations When Using a 4×8 Waterjet

While powerful, understanding the operational aspects is important:

Operating Costs: The primary consumables are high-pressure water pumps (maintenance), electricity, abrasive garnet (significant cost, especially for thick materials), and water (often recycled, but filtration is needed). Garnet disposal is also a factor.

Cutting Speed: Can be slow for thick, dense materials compared to plasma or thick metal lasers. Speed vs. quality is often a trade-off.

Edge Taper & Finish: While manageable, inherent taper exists in thicker cuts, and the edge has a matte, textured finish. Requires taper compensation for precision parts and secondary finishing (sanding, polishing) if a smooth or polished edge is needed.

Noise: Waterjet pumps and the cutting process itself generate significant noise, requiring appropriate hearing protection and potentially sound enclosures.

Material Handling: Moving full 4×8 sheets of heavy materials (like stone or thick metal) requires proper equipment (cranes, forklifts, vacuum lifters) and safety protocols.

The 4×8 waterjet stands as a cornerstone technology in modern manufacturing and fabrication. Its ability to precisely cut virtually any material up to significant thicknesses, all within the confines of the globally standard 4×8 foot sheet size, provides unparalleled versatility and practicality. The absence of heat distortion, capability for intricate designs, and cold-cutting process make it the go-to solution for countless applications across aerospace, automotive, architecture, art, signage, and general metalworking. While operational costs and cutting speeds for thick materials are factors, the unique advantages offered by the 4×8 waterjet – particularly its material-agnostic nature and precision on a standard platform – ensure its continued dominance as an essential tool for businesses demanding flexibility, quality, and the ability to tackle diverse cutting challenges efficiently. For anyone regularly working with sheet materials in this common size and requiring precision cutting across a broad material spectrum, investing in or utilizing the services of a 4×8 waterjet is a strategic and powerful choice.

continue reading

Related Posts

- 1077 words5.4 min read

- 1175 words5.9 min read

- 1255 words6.3 min read