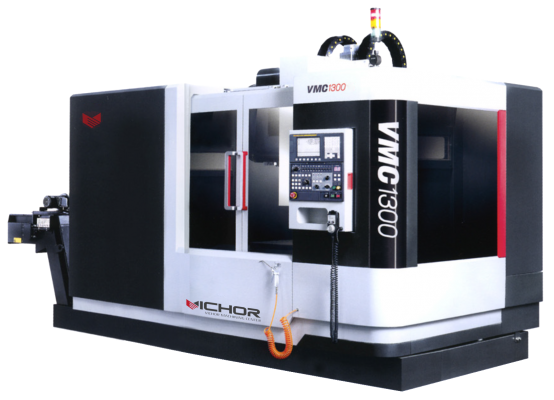

VICHOR VMC1300

Excellent performance and user friendly operation.

Advance FANUC Oi-MD CNC system.

Direct coupled spindle and axis motors provide superb performance characteristics.

Compact footprint permits maximum utilization of floor space, and more easily enables the creation of production lines.

Spindles with High Accuracy and Torque

High powered spindle outputs high torque and high quality, suitable for heavy cutting and precise rigid tapping. Spindle of 6000 RPM BT50 is standard. ZF gearbox, BT 40 spindle with 8000 and 10000 RPM are optional.

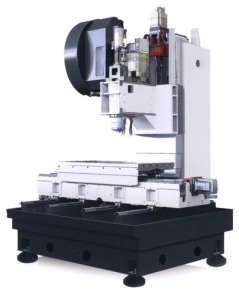

High Accuracy, High Rigidity

Vibration dampening design is applied to the main components of these machines such as the bed, column, and headstock, so that such vibration is kept to a minimum. Since the frame structure also provides great rigidity,heavy cutting with high accuracy is achieved.

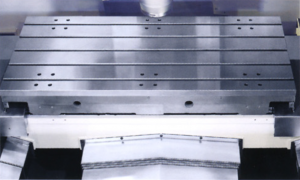

Worktable with High Machining Area

Compared with similar machines in the same class, the ultra-large worktable, larger travels and heavier bearing capacity of these machines permit the machining of much larger and heavier workpieces.

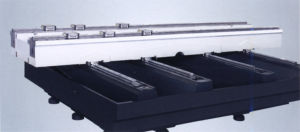

Six Bearing Blocks – four Linear Guideways

The structure of the X axis with 6 bearing blocks, and the Y axis with 4 linear guideways, along with reinforced box-type body casting structure which provides extremely good rigidity, all enable the machine to realize excellent cutting performance and accuracy under heavy machining conditions.

GENERAL INTRODUCTION

Vertical machining center is mainly used for the processing of plate items, disc-type parts, housing parts, mould and other parts with high precision accuracy, working procedures and complex shapes. It can also be used to complete the precision machining for the milling, drilling, reaming, hinging, precise boring, tapping, 2D and 3D curved surface and angular surface continuously in one clamping cycle time to realize routinization and shortened production cycle, allowing the good economic benefits brought to the users.

VICHOR VMC1300 Vertical Machining Center is one of the products developed with independent intellectual property rights by our company. The machine tool is adopted by the mechatronics structure and is applied with 3D design software (Pro/E) and finite element analysis software (ANSYS) to achieve design optimization, so as to make it more reasonable in structure and design and more perfectible in rigidity, precision maintenance and reliability. Through the introduction of the advanced design concepts and the scientific design methods, the traditional design problems can be solved accordingly.