VICHOR VMC1100

Excellent performance and user friendly operation.

Advance FANUC Oi-MD CNC system.

Direct coupled spindle and axis motors provide superb performance characteristics.

Compact footprint permits maximum utilization of floor space, and more easily enables the creation of production lines.

The Structure with High Accuracy and Rigidity

Reasonable design of bed, column, slider and spindle headstock ensures the high rigidity during machine running, and minimizes the thermal deformation due to heavy cutting.

Frame Structure for High Speed, High Accuracy, and High Rigidity X and Y axes adopt linear guideways, and the Z-axis has cast-iron box ways in order to reduce vibration from high-torque cutting and ensure high accuracy and excellent work-piece quality and finish.

Spindle configurations for high accuracy and different applications Standard spindle configuration is 7000 RPM and BT40 specification. Optional configurations are 10000/12000 BT40, or BT50 at 6000 RPM ZF 1:4 gearbox option provides output torque of up to 380 Nm for applications requiring higher torque.

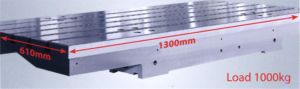

Comparing with the same class production, it can bear larger load and machine the part with larger size.

GENERAL INTRODUCTION

Vertical machining center is mainly used for the processing of plate items, disc-type parts, housing parts, mould and other parts with high precision accuracy, working procedures and complex shapes. It can also be used to complete the precision machining for the milling, drilling, reaming, hinging, precise boring, tapping, 2D and 3D curved surface and angular surface continuously in one clamping cycle time to realize routinization and shortened production cycle, allowing the good economic benefits brought to the users.

VICHOR VMC1100 Vertical Machining Center is one of the products developed with independent intellectual property rights by our company. The machine tool is adopted by the mechatronics structure and is applied with 3D design software (Pro/E) and finite element analysis software (ANSYS) to achieve design optimization, so as to make it more reasonable in structure and design and more perfectible in rigidity, precision maintenance and reliability. Through the introduction of the advanced design concepts and the scientific design methods, the traditional design problems can be solved accordingly.