VICHOR VMC700

Excellent performance and user friendly operation.

Advance FANUC Oi-MD CNC system.

Direct coupled spindle and axis motors provide superb performance characteristics.

Compact footprint permits maximum utilization of floor space, and more easily enables the creation of production lines.

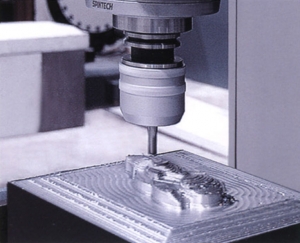

Well-engineered Structural Design

The spindle is directly coupled to the spindle motor, which reduces start/stop time, and greatly improves machining efficiency. It is especially suited to the machining of aluminum parts and moulds. The standard configuration of the spindle is BT40 and 8000 RPM, with the options of 10000 or 12000 RPM with BT40 or BT30.

Tool Magazine with High Reliability

Very Reliable Tool Magazine. The tool changer mechanism is arm-type with very fast tool-tool time, for most efficient machining possible. AII three axes have linear guideways and the Z axis has no balance weight, which ensures that all axes move at high speed,thus reducing any noncutting time to a minimum.

Chip Conveyor

Powerful chip clearing flood coolant nozzles and spiral chip conveyors located on either side of the table in conjunction with separator-type cooling tank and high flow coolant pump greatly reduce the heat distortion caused by the machining process.

High Speed, High Efficiency, and High Reliability are Assured

High Speed, High Efficiency, and High Reliability are Assured

The spindle is directly coupled to its motor, thus reducing the start/stop times,and greatly improving the efficiency of the machine. The machine is especially suitable for machining aluminum parts and moulds. The standard spindle configuration is BT40 with 8000 RPM,and optional configurations of 10000 or 12000 RPM are available (BT40 and BT30) Spindle start time (0-12000 RPM) is 1.5 seconds. Ball screws of large pitch are directly connected to the axis servo motors and rapid feeds of up to 48 meters/minute can be achieved. These machines are ideally suited to mass production applications and the machining of moulds.

GENERAL INTRODUCTION

Vertical machining center is mainly used for the processing of plate items, disc-type parts, housing parts, mould and other parts with high precision accuracy, working procedures and complex shapes. It can also be used to complete the precision machining for the milling, drilling, reaming, hinging, precise boring, tapping, 2D and 3D curved surface and angular surface continuously in one clamping cycle time to realize routinization and shortened production cycle, allowing the good economic benefits brought to the users.

VICHOR VMC750 Vertical Machining Center is one of the products developed with independent intellectual property rights by our company. The machine tool is adopted by the mechatronics structure and is applied with 3D design software (Pro/E) and finite element analysis software (ANSYS) to achieve design optimization, so as to make it more reasonable in structure and design and more perfectible in rigidity, precision maintenance and reliability. Through the introduction of the advanced design concepts and the scientific design methods, the traditional design problems can be solved accordingly.